Natural potato chips and producing process thereof

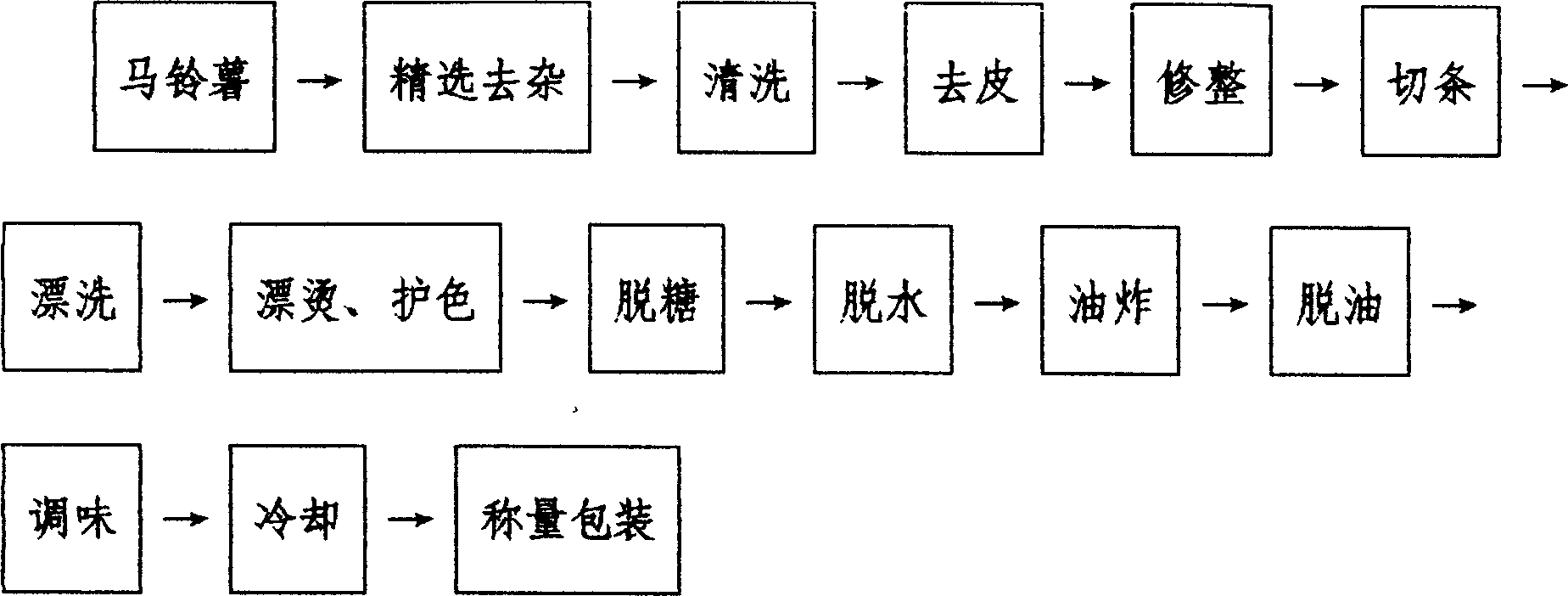

A production process, French fries technology, applied in the field of natural French fries production technology, can solve the problems of non-oil removal, poor color, not crispy taste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] 1. Select 1,000 kg of potato raw materials as required.

[0025] 2. Firstly, clean and peel the raw materials.

[0026] 3. Put the raw materials into the cleaning machine to wash away the sediment and other sundries. After cleaning, put them into the peeling machine to remove the outer skin, then dig out the bud eyes and mildewed parts and peel off the parts that do not meet the cutting requirements.

[0027] 4. Then do the preparatory work before frying, and deform the raw materials-cutting strips, extracting starch, and desugaring.

[0028] 5. Put the prepared clean and regular potatoes that meet the cutting standards into the cutting machine and cut them into strips of about 4-5 cm.

[0029] 6. Put it directly into clean water to wash off the starch on the surface of the sliver.

[0030] 7. In order to reduce the maturation time during frying, the slivers after removing the starch should be put into water at 80-100° C. and added with a small amount of color protect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com