Correcting method for electronic part mounting device and device for using said method

A calibration method and component technology, applied to measuring devices, electrical components, projection devices, etc., can solve problems such as time-consuming and complicated calibration operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, a method for correcting a position recognition camera, an apparatus thereof, and an electronic component mounting apparatus using a jig substrate and a jig component for correcting the position of a recognition camera according to an embodiment of the present invention will be described with reference to the accompanying drawings.

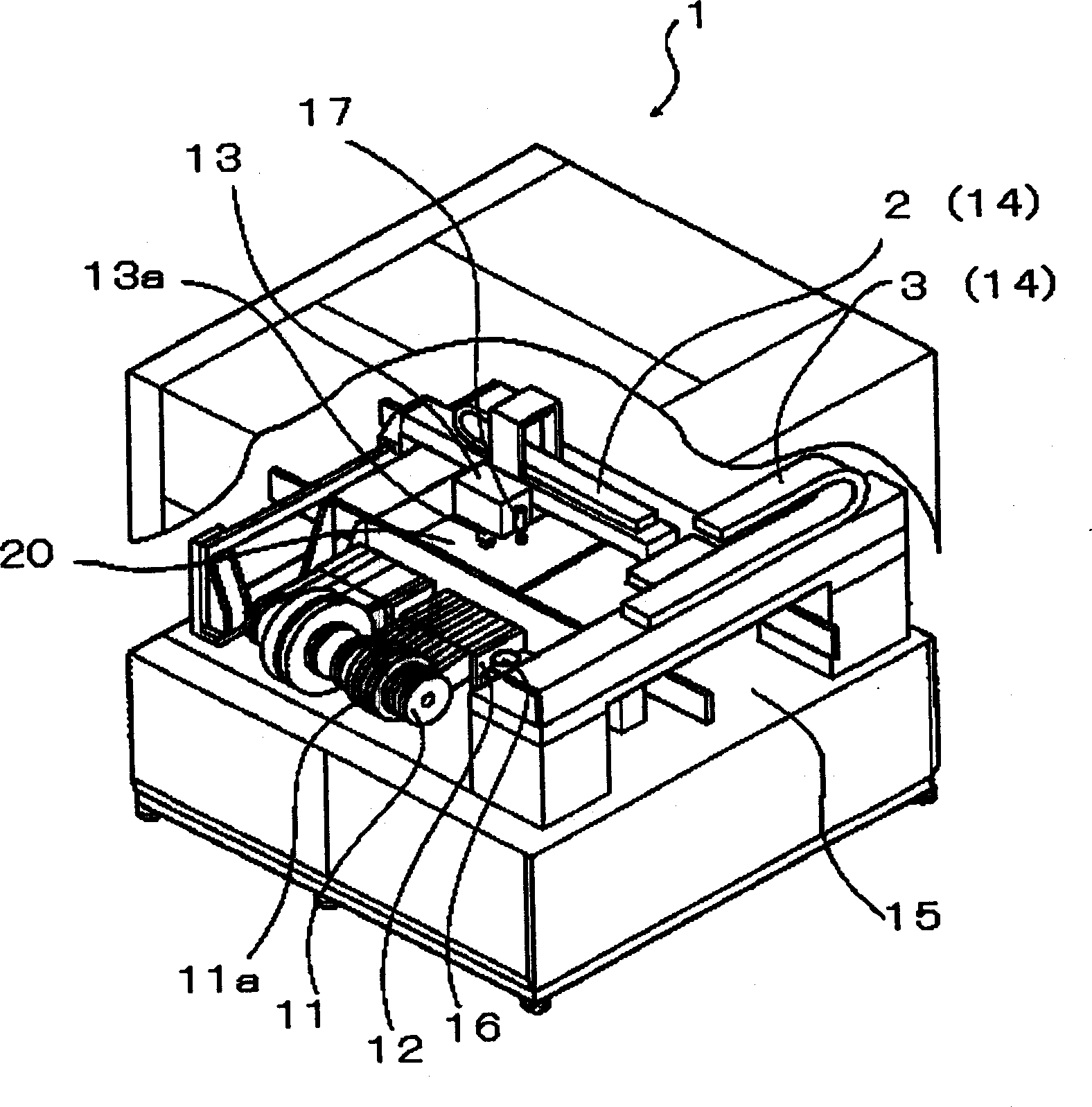

[0027] This electronic component mounting apparatus 1 is a so-called multifunctional component mounting machine, and is configured to mount various electronic components such as surface mount components such as chip capacitors and chip resistors, and multi-lead components such as QFPIC.

[0028] figure 1 It is a schematic diagram of the electronic component mounting apparatus. As shown in this figure, the electronic component mounting apparatus 1 has: a component supply unit 12, and a substrate conveyance path 15 extending from the central part in the left and right directions slightly behind, and is arranged on the electronic co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com