Controller for electric spark line processing machine tool

A technology for processing machine tools and electric discharge wires, which is applied to electric processing equipment, metal processing equipment, circuits, etc., and can solve problems such as reduced processing accuracy and high discharge pulse intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

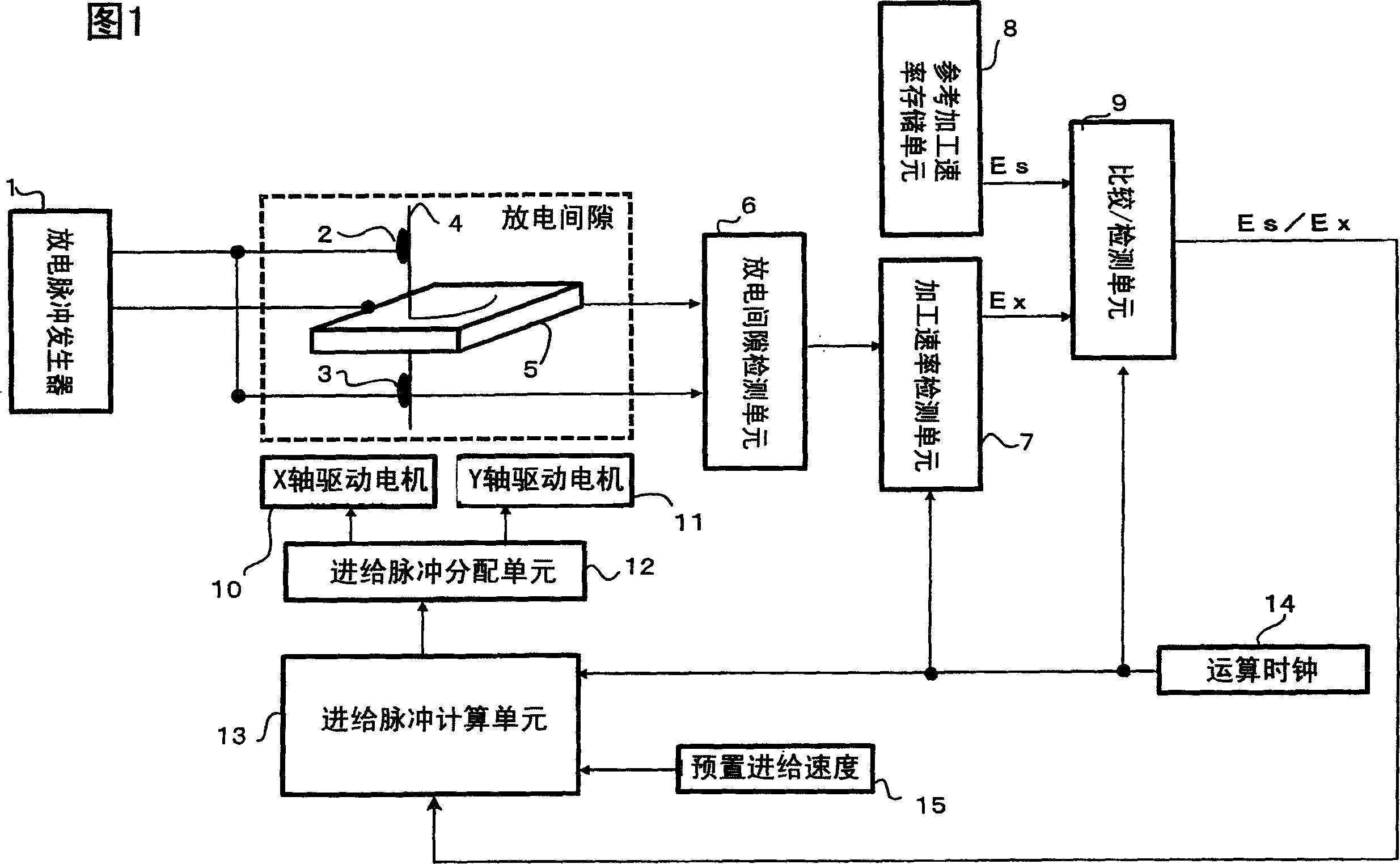

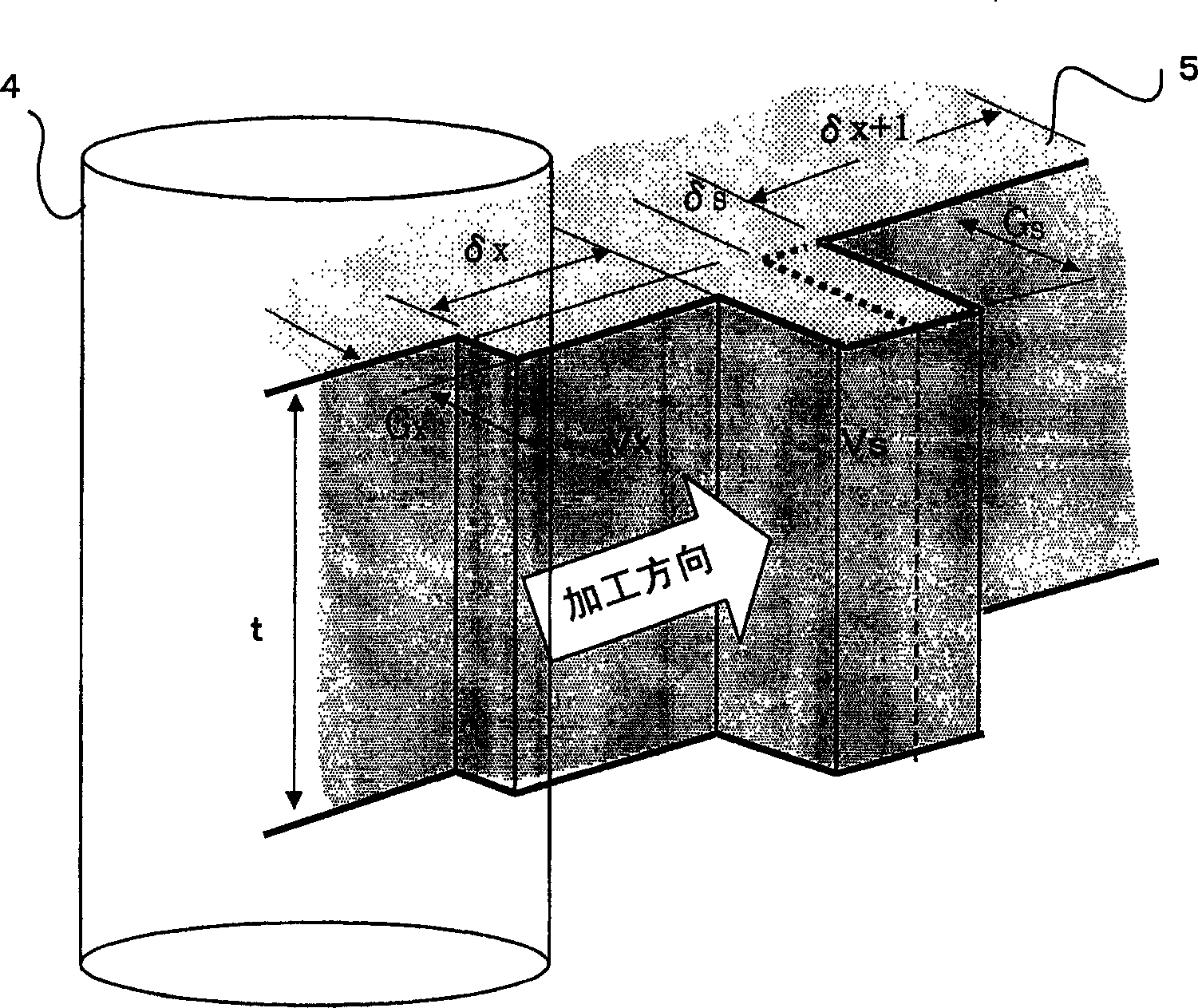

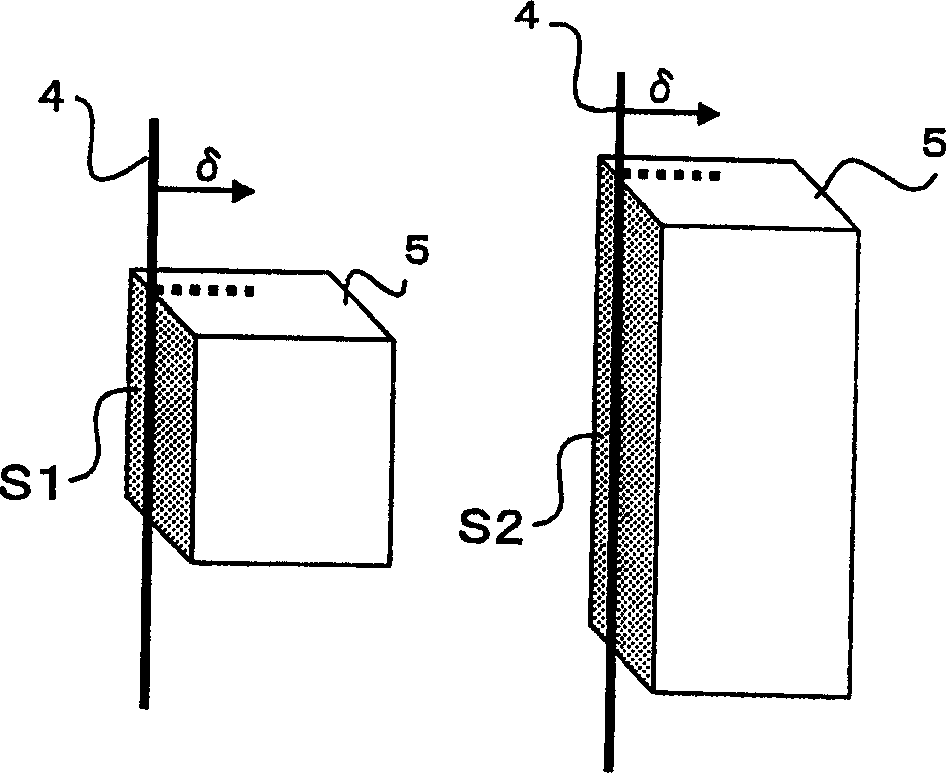

[0043] Fig. 1 is a block diagram showing relevant parts of a controller of a wire electric discharge machining machine according to the present invention. The discharge pulse generator 1 applies a discharge pulse voltage to the gap between the wire electrode 4 and the workpiece 5 for discharge machining, and includes a DC power supply, a circuit including a switching element such as a transistor, a charging and discharging circuit of a capacitor, and the like. The conductive brushes 2 and 3 pass current through the wire electrodes, and are connected to one of both ends of the discharge pulse generator 1 . The workpiece 5 is connected to the other end of the discharge pulse generator 1 . The discharge pulse generator 1 applies a pulse voltage between the moving wire electrode 4 and the workpiece 5 . The table (not shown) on which the workpiece 5 is placed is driven by the X-axis drive motor control unit 10 , the Y-axis drive motor control unit 11 and the pulse distribution uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com