Fixture for video camera onto base board of tripod

A technology for a camera and a locking device, which is applied to the machine/stand, the body of the camera, the camera, etc., and can solve the problem of the camera being unstable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

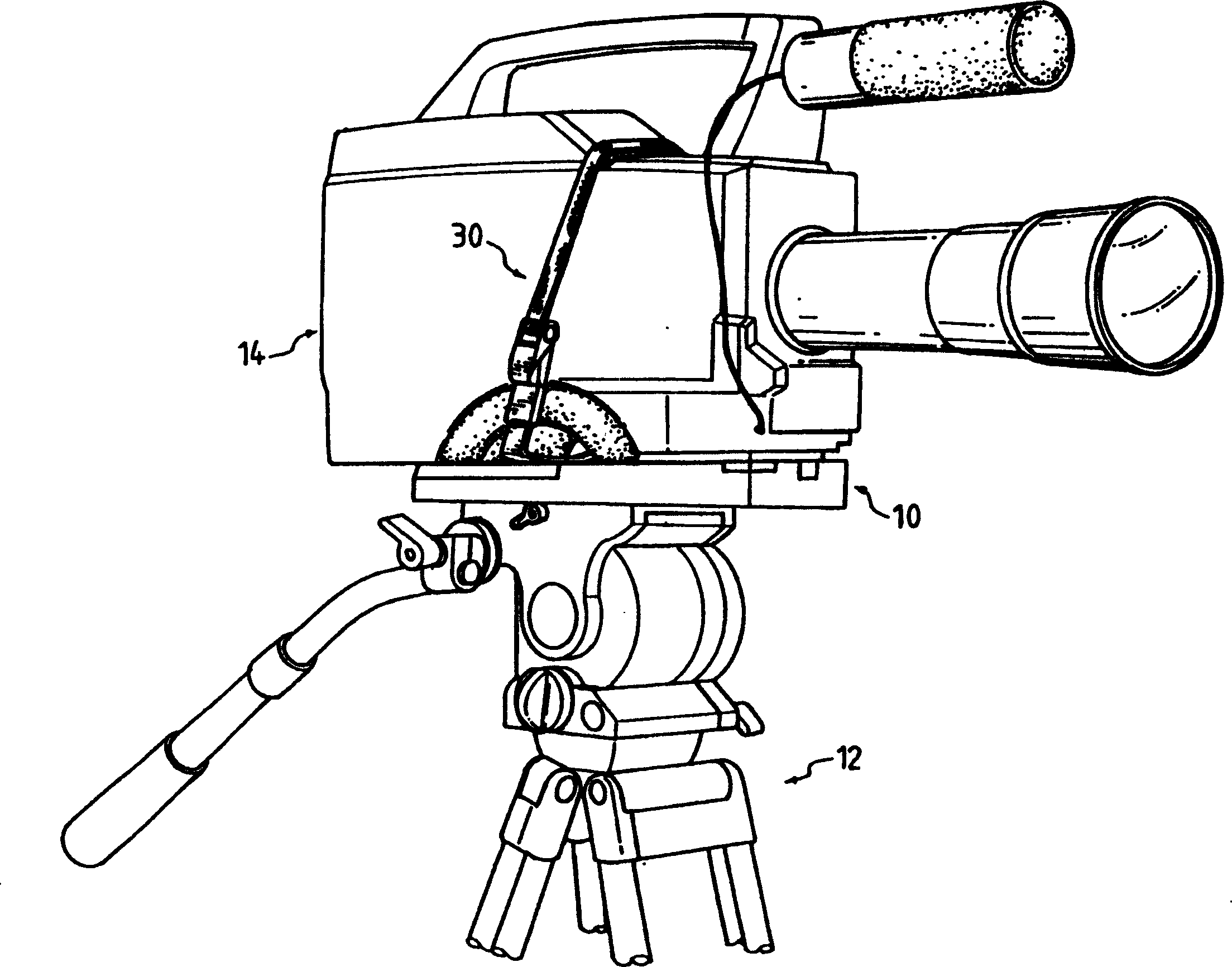

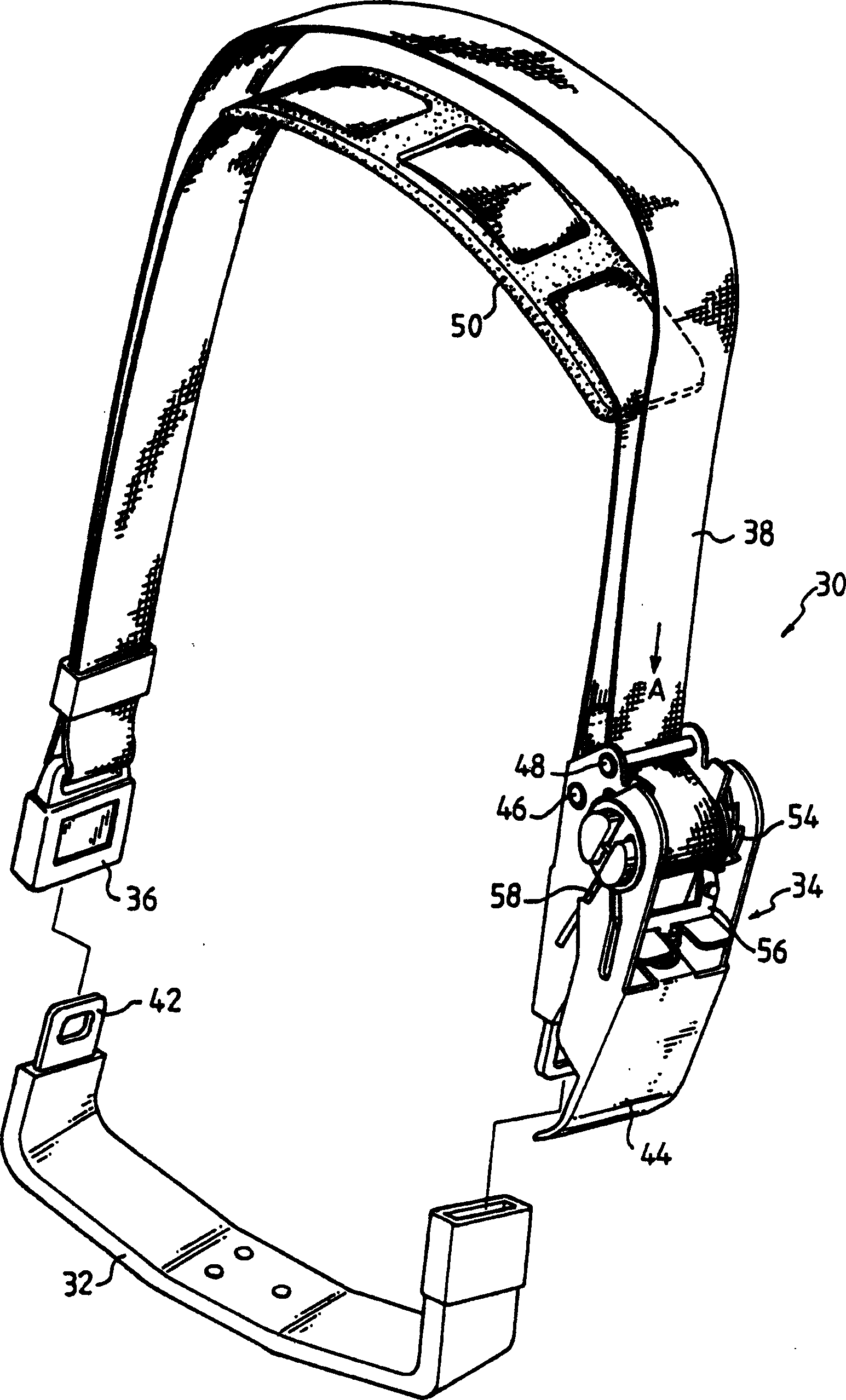

[0021] Now refer to figure 2 , with reference numeral 30 designating a device for fixing a camera 14 on a tripod with a base plate. Details of device 30 are shown in image 3 . The device 30 mainly includes: a seat portion 32 , a tension member 34 , a locking device 36 and a buckle 38 .

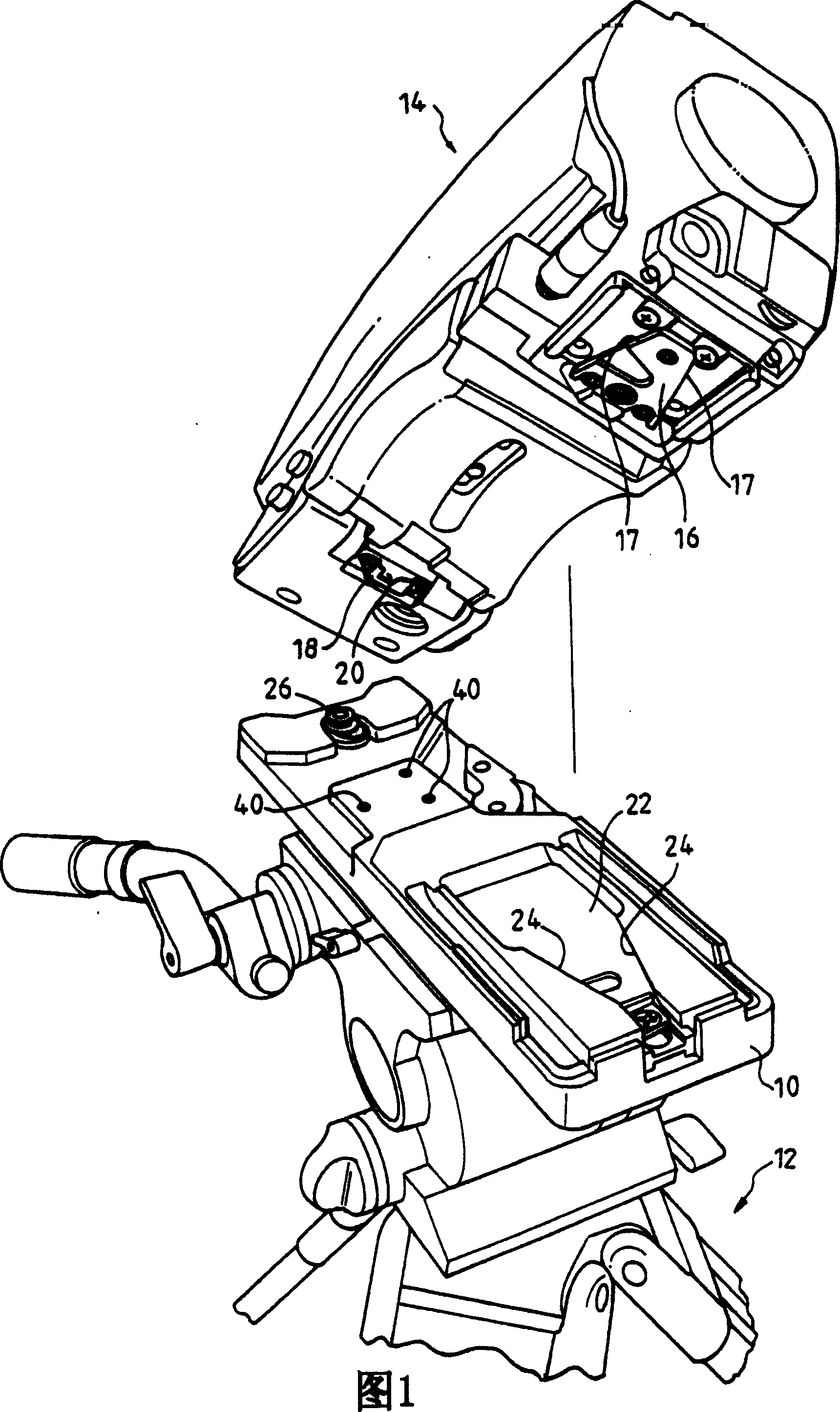

[0022] The seat 32 is generally designed to match the contour of the bottom of the camera 14 and can be fixed to the base plate 10 by screws. It should be noted here that the base plate 10 provided by the camera supplier already includes the screw hole 40 ( FIG. 1 ), and this has become a standard configuration of each base plate supplier. The seat 32 may contain the same number of openings so that it can be properly fastened to the base plate 10 by screws. Seat 32 is generally U-shaped with a locking member 42 at each end, such as a conventional latch or conventional latch release. image 3 The tensioning member 34 shown can be made by modifying commercially available tensioning devices...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com