Apparatus and method for heating filament yarn

A heating device, filament technology, used in textiles and papermaking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

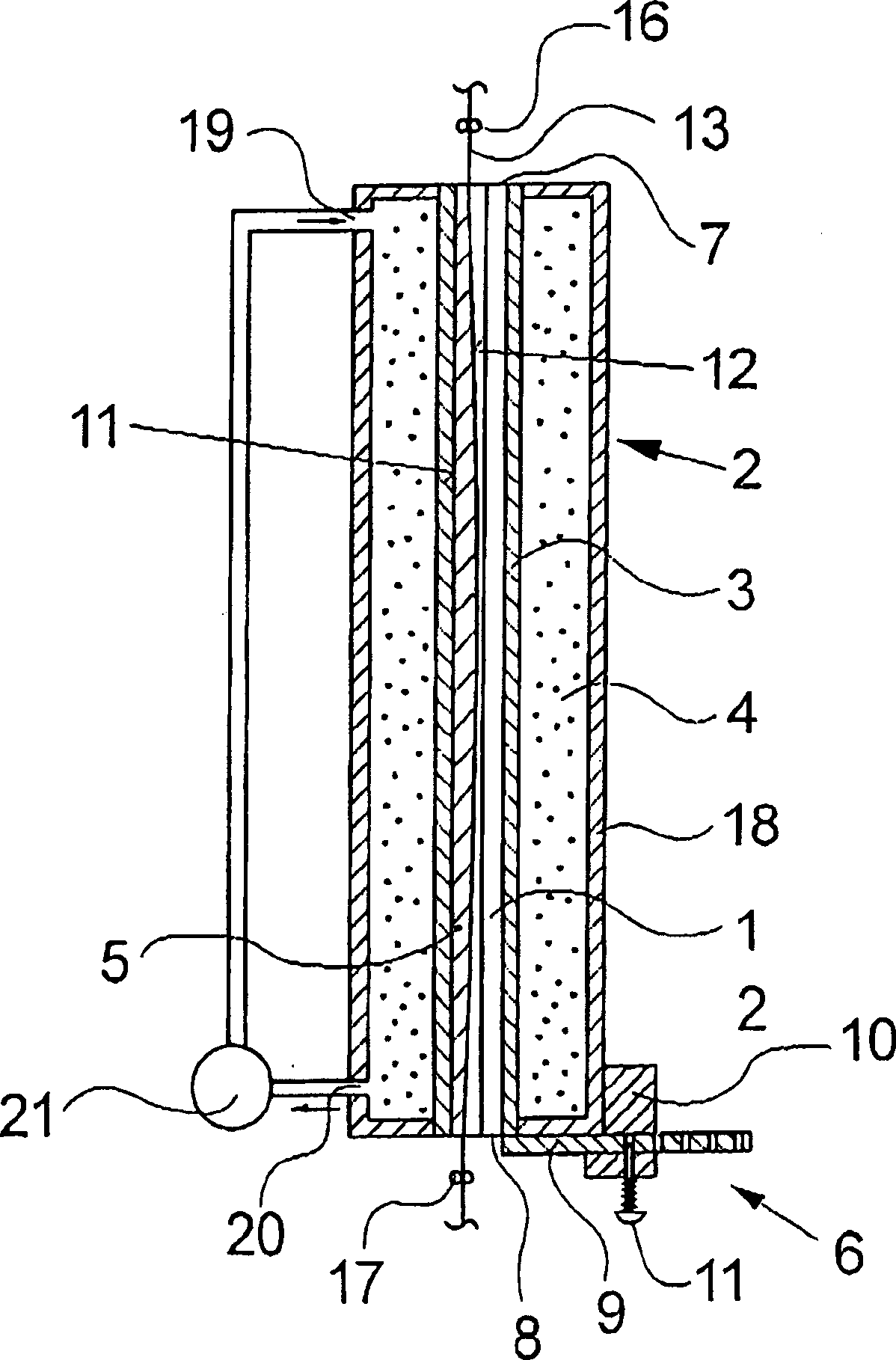

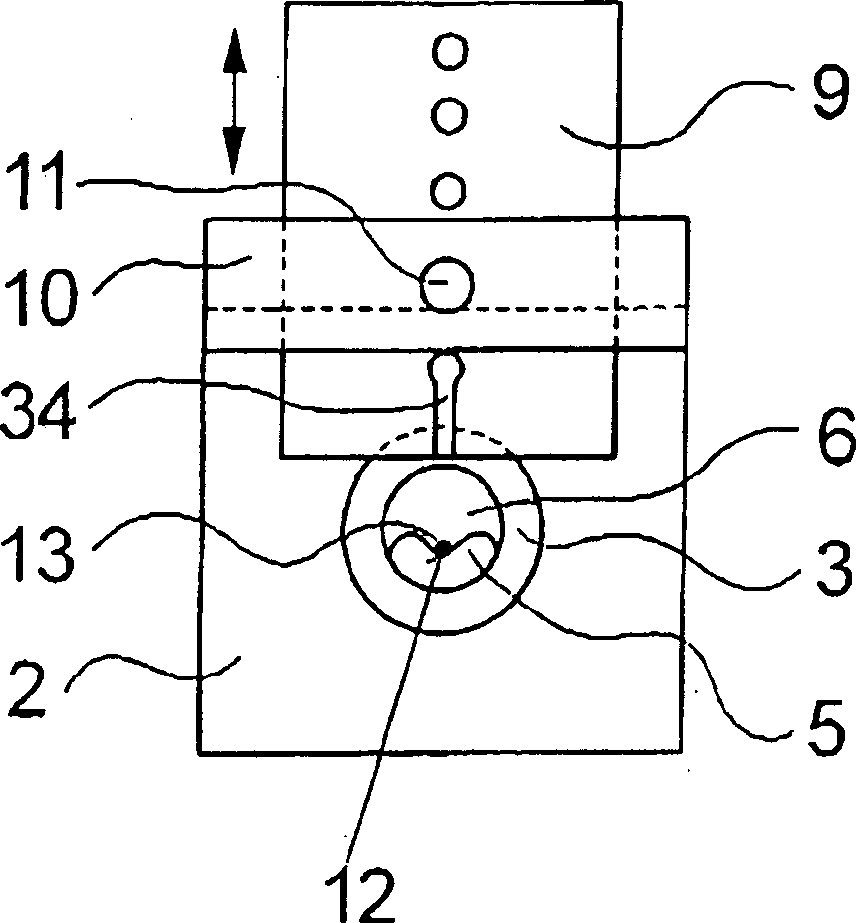

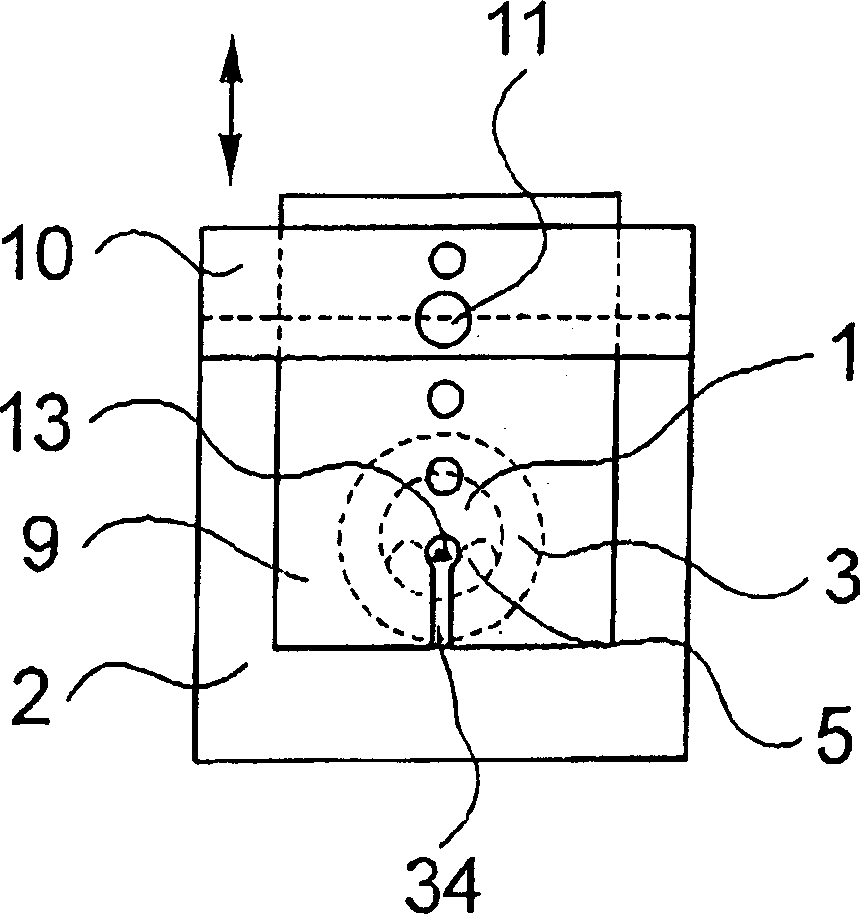

[0028] exist figure 1 shows schematically a longitudinal section through a first embodiment of a heating device according to the invention, which can be used, for example, in a texturing machine to heat texturized filaments for stress treatment in the shrinkage zone. FIG. 2 shows a front view of an exemplary embodiment of a heating device according to the invention. The following description applies to both figures unless specifically stated for one figure.

[0029] An exemplary embodiment of the heating device according to the invention has a long heating channel 1 with a wall 3 . In the present embodiment, the heating channel 1 with the wall 3 is formed by a thin-walled tube. The heating channel 1 is open at the end faces. An insert 5 is inserted into the heating channel 1 . The insert 5 has a longitudinal groove 12 in which the filaments 13 run in contact therewith. For this purpose, the longitudinal grooves 12 have a curvature on the groove base which is arranged in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com