Sewing machine

A sewing machine and needle technology, applied in the field of sewing machines, can solve the problems of good operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

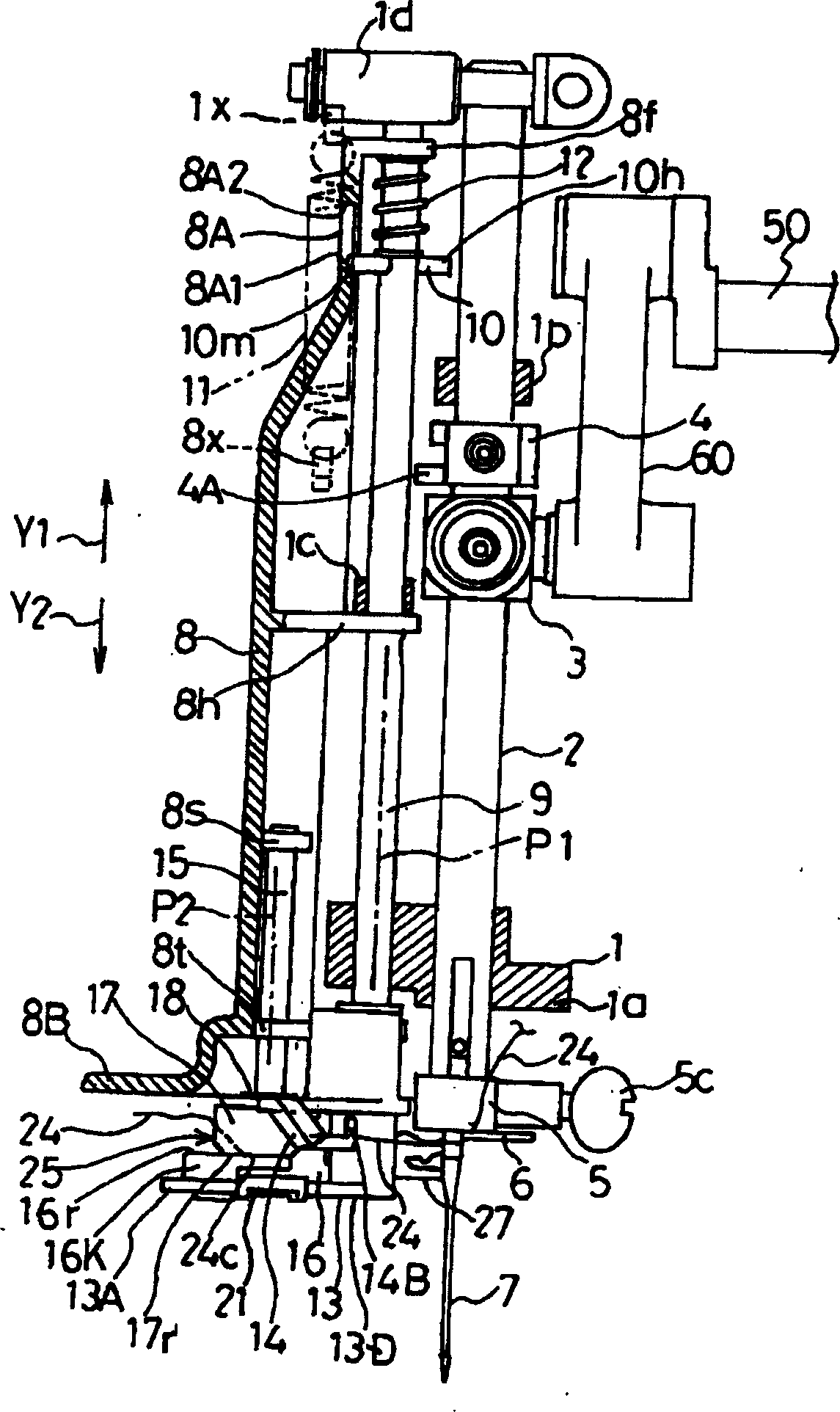

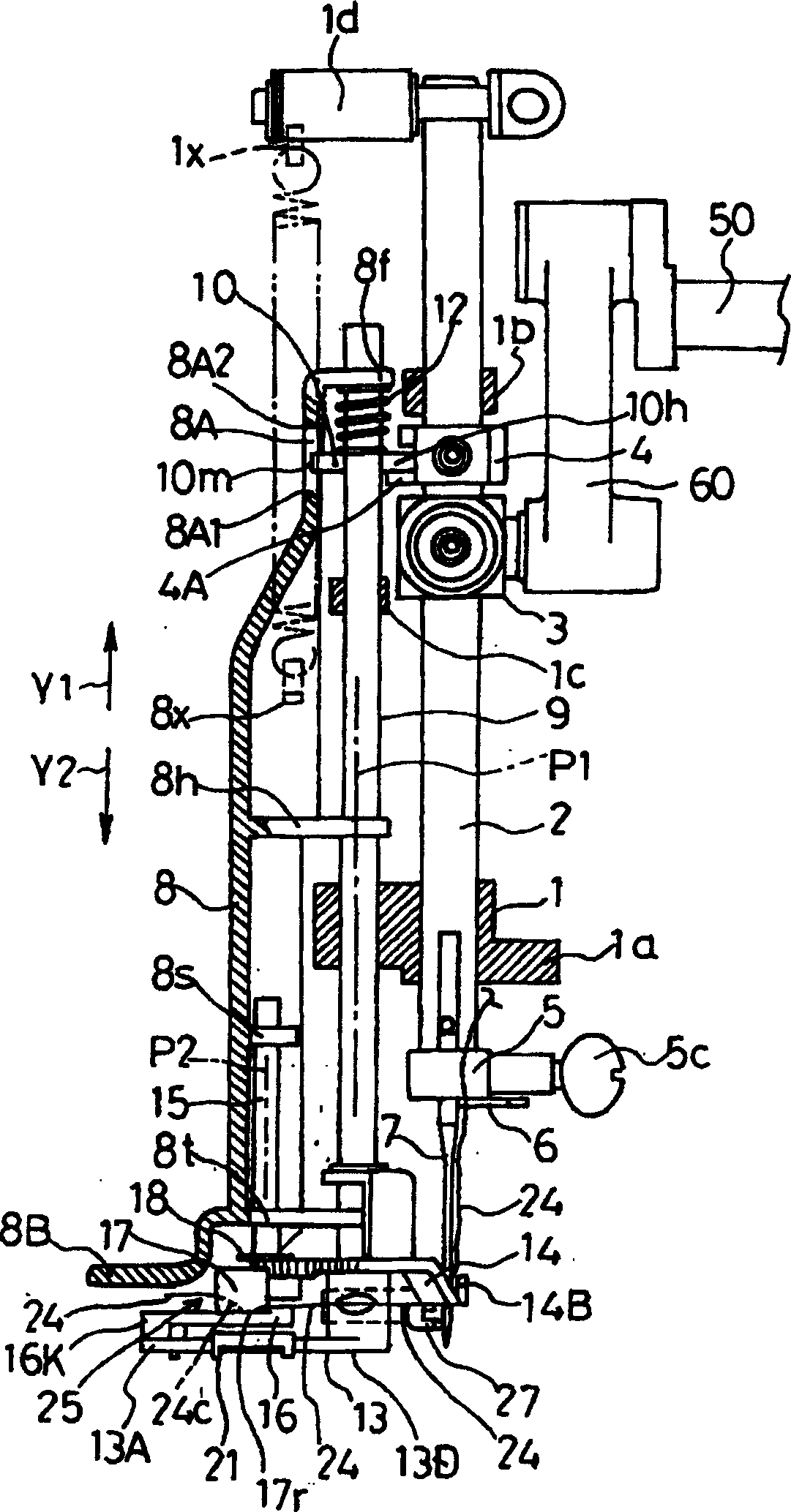

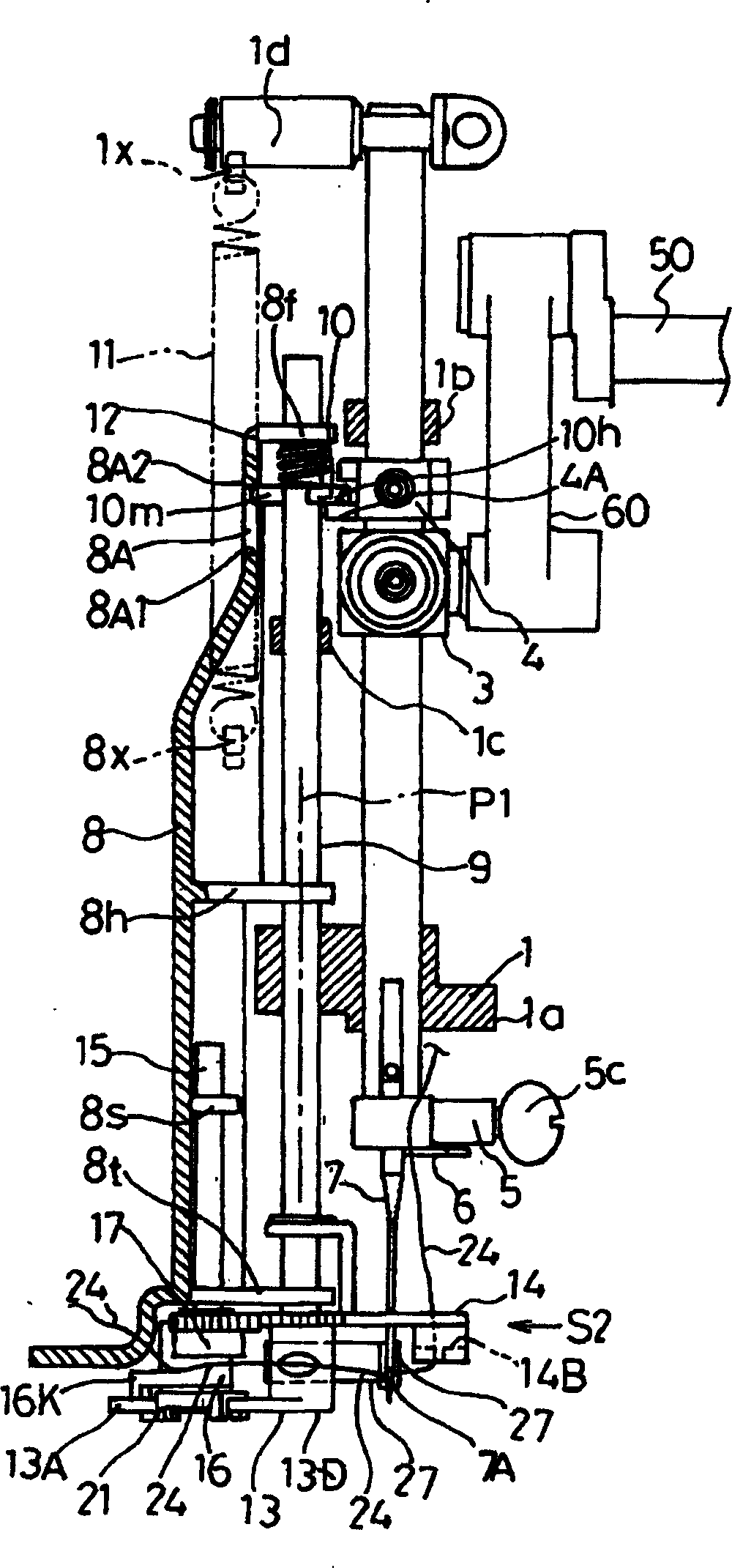

Embodiment Construction

[0026] According to the sewing machine of the present invention, at least one of the following solutions can be adopted.

[0027] A threading lever that holds a threading hook rotatably provided on the needle bar arm may be provided, and the thread guide is rotated in a direction opposite to that of the threading hook in conjunction with the threading lever as the threading lever rotates. scheme of the gear mechanism. At this time, it is possible to insert the hook of the threading hook into the eye of the machine needle by rotating the threading lever around its axis in accordance with the operation of the operating lever, so that the threading hook and the thread guide rotate in opposite directions to each other. scheme. The rotation of the threading hook body and the rotation of the thread guide body can be synchronized. It is possible to employ a speed-increasing mechanism that makes the rotation speed of the thread guide that holds the thread in the horizontal direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com