Driving device fr calendering roller

A technology of transmission device and calender roll, which is applied in the direction of textiles and papermaking, winding mechanism, fiber processing, etc., and can solve problems such as slipping, gear wear, and unfavorable low-noise equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

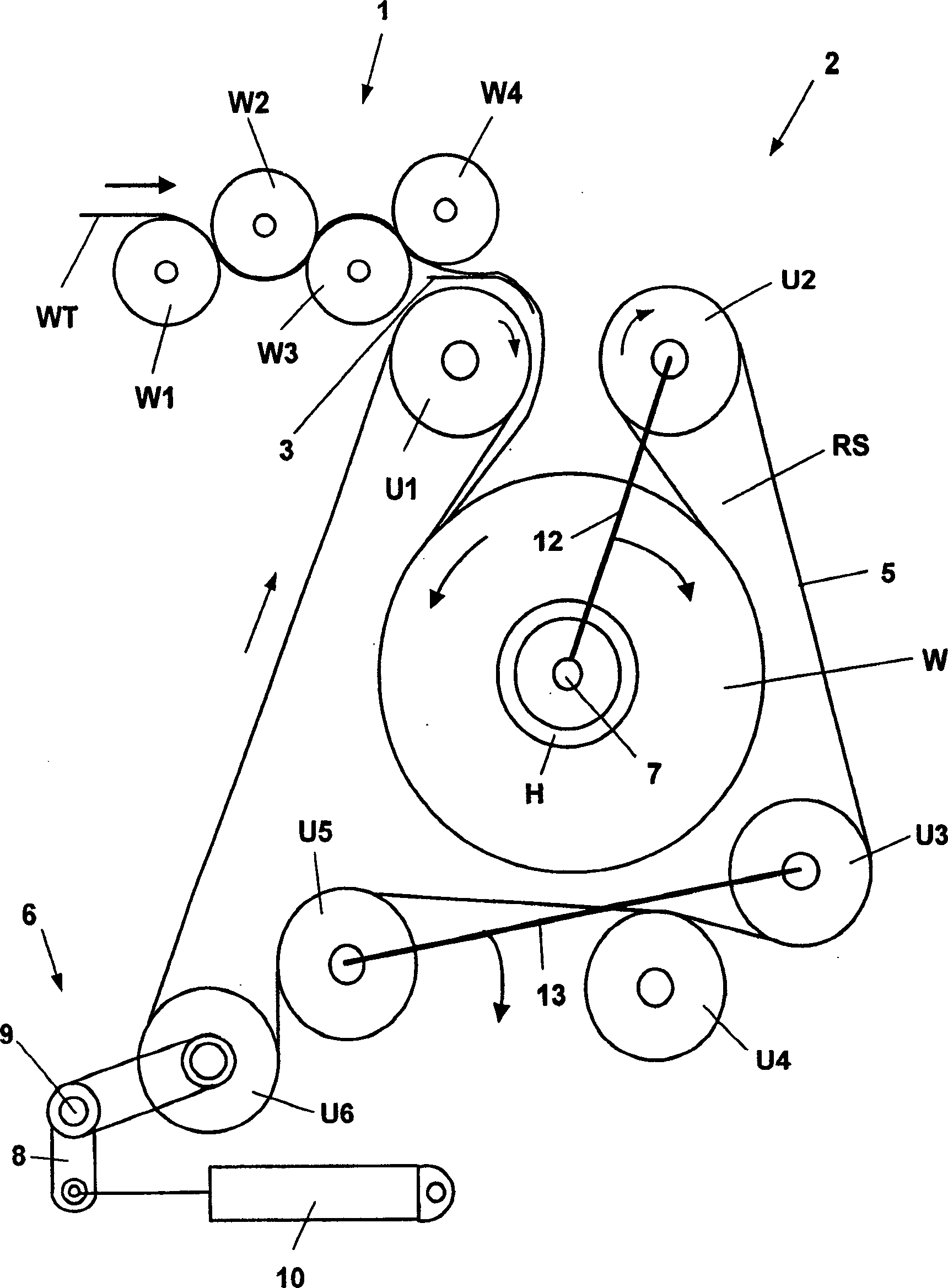

[0025] figure 1 A set of calender rolls 1 is shown which consists of four calender rolls W1-W4 arranged one behind the other. The calender rolls are arranged slightly staggered back and forth, and between the calender rolls the cotton WT is conveyed meanderingly to a subsequent roll-forming device 2 . Furthermore, the cotton WT passes through a slope 3 between the two deflection rollers U1 and U2, below which there is a belt loop RS of a belt 5 which is guided by the other deflection rollers U3, U4, U5 and U6. A small roll W is formed within the belt loop RS, in which the cotton WT is wound on a sleeve H. The sleeve H is supported rotatably about the axis 7 by means of transverse supports (not shown in detail). The belt 5 of the roll forming device 2 is tensioned by means of deflection rollers U6 which are arranged to be rotatable in relation to the axis of rotation 9 by means of a double arm lever 8 . The double arm rod 8 receives the force of a cylinder 10 mounted in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com