Elevator building project layout mode

A technology of civil engineering and elevators, which is applied in the directions of elevators, transportation and packaging in buildings, and can solve the problems of large machine room area, occupied space, and large occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

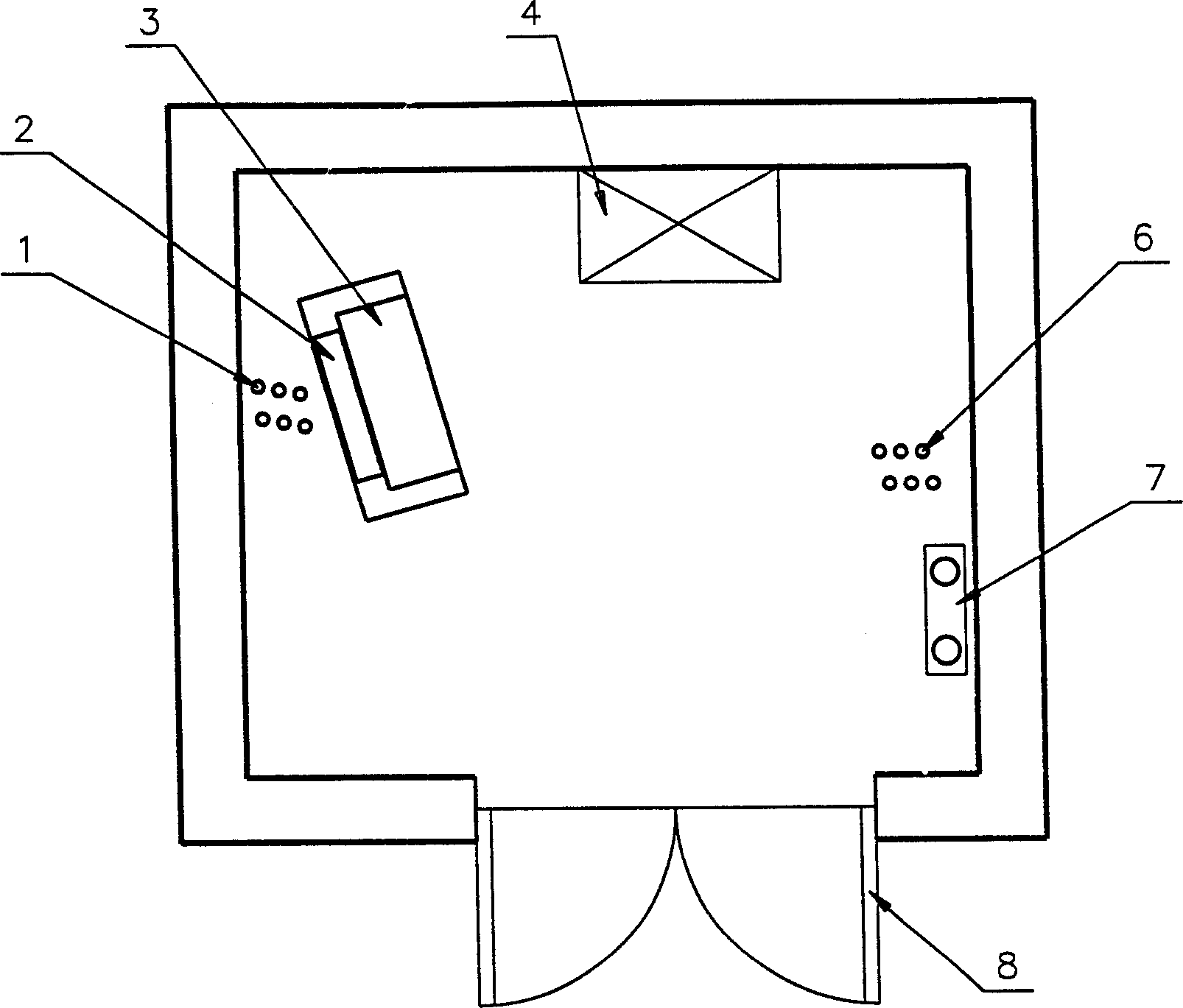

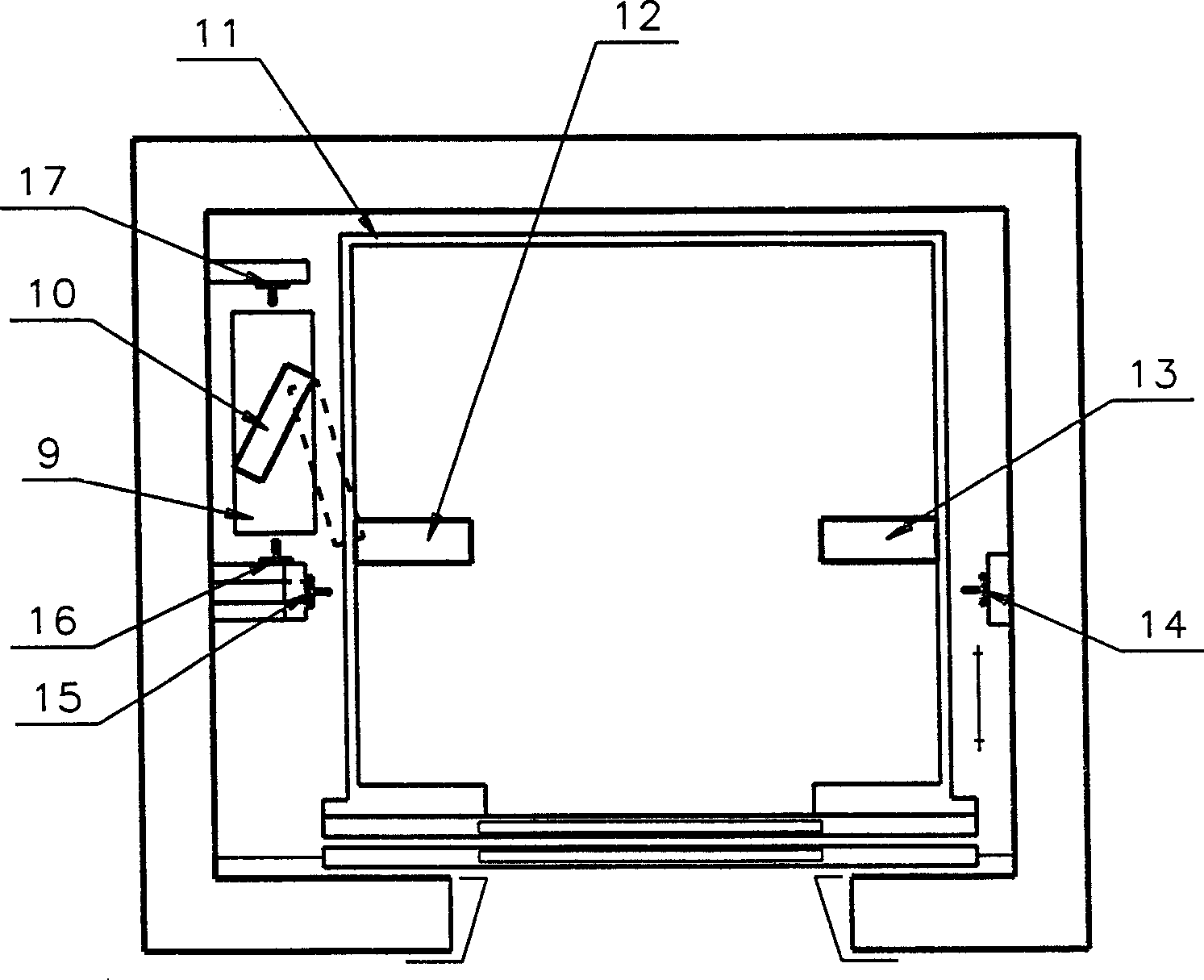

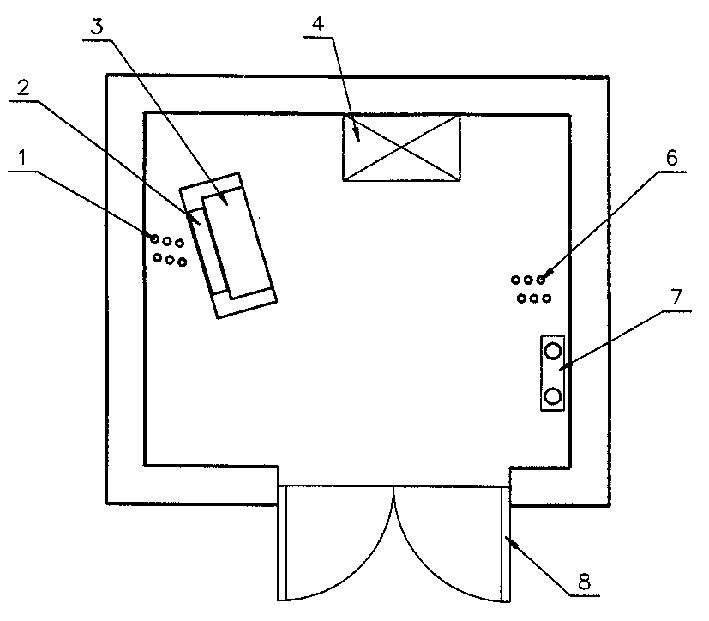

[0011] An elevator civil construction layout method, in which the planes of the elevator machine room and the hoistway are completely equal, the wall of the machine room extends vertically upward from the hoistway, and the traction equipment (3) is arranged in the machine room at the upper part of the hoistway, and is kept at the same level as the left wall of the hoistway The deflection angle is conducive to the arrangement of the wire rope. The traction wire rope is suspended on the traction sheave (2) of the traction device (3), and goes around the counterweight (9) from one side of the traction sheave (2) downwards. Heavy anti-rope pulley (10) enters the rope end (6) of machine room car side upwards and is close to the machine room wall on the right side again. Such as figure 2 Shown, control panel (4) and overspeed governor (7) all arrange in the machine room near wall position, make machine room door (8) to the center of machine room. There is a clear area left for pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com