Spin-drying controlling method for drum washer

The technology of a drum washing machine and a control method, which is applied to the control device of the washing machine, other washing machines, spin dryers, etc., can solve the problems of reduced reliability of eccentricity detection, reduced drying performance of the washing machine, damage to washing machine parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, preferred embodiments of the present invention will be described with reference to the accompanying drawings.

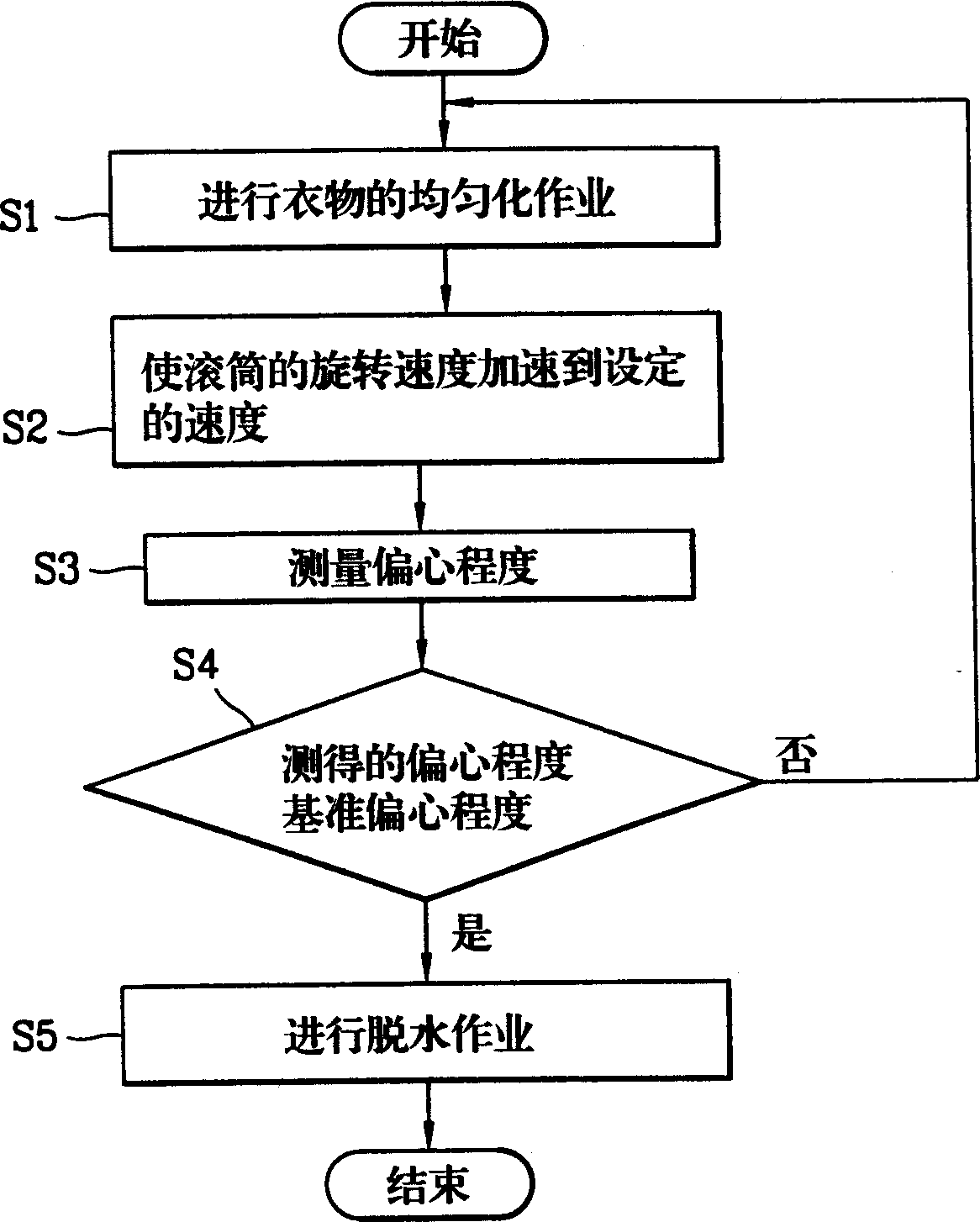

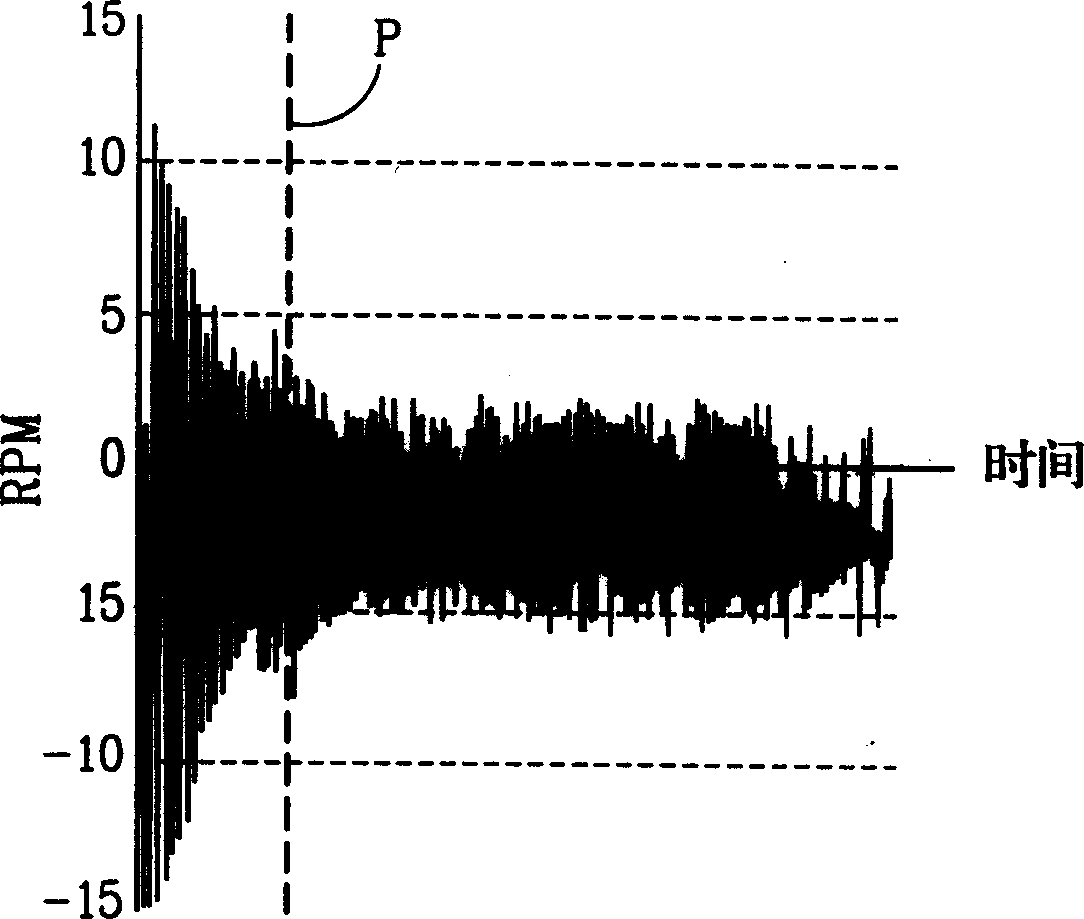

[0039] Figure 5 is a block diagram illustrating the spin drying control device of the drum washing machine according to the present invention; Image 6 is a flow chart illustrating the spin-drying control method of the drum washing machine according to the present invention; and Figure 7 It is a graph showing the measurement procedure of the degree of eccentricity in the spin-drying operation according to the present invention.

[0040] The spin-drying control device of the present invention includes: a rotational speed per minute detection device 50 installed on the driving motor for driving the drum and used to detect the rotational speed per minute of the driving motor; A control device 60 for judging the degree of eccentricity generated by a signal from the control device 60 ; and a drive motor 70 for adjusting the rotation speed of the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com