Drawing frame for a spinning machine

A drafting device and spinning machine technology, applied in the field of aprons, can solve the problems of stick-slip effect, increased wear, premature replacement of aprons, etc., and achieve the effect of wear resistance and friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

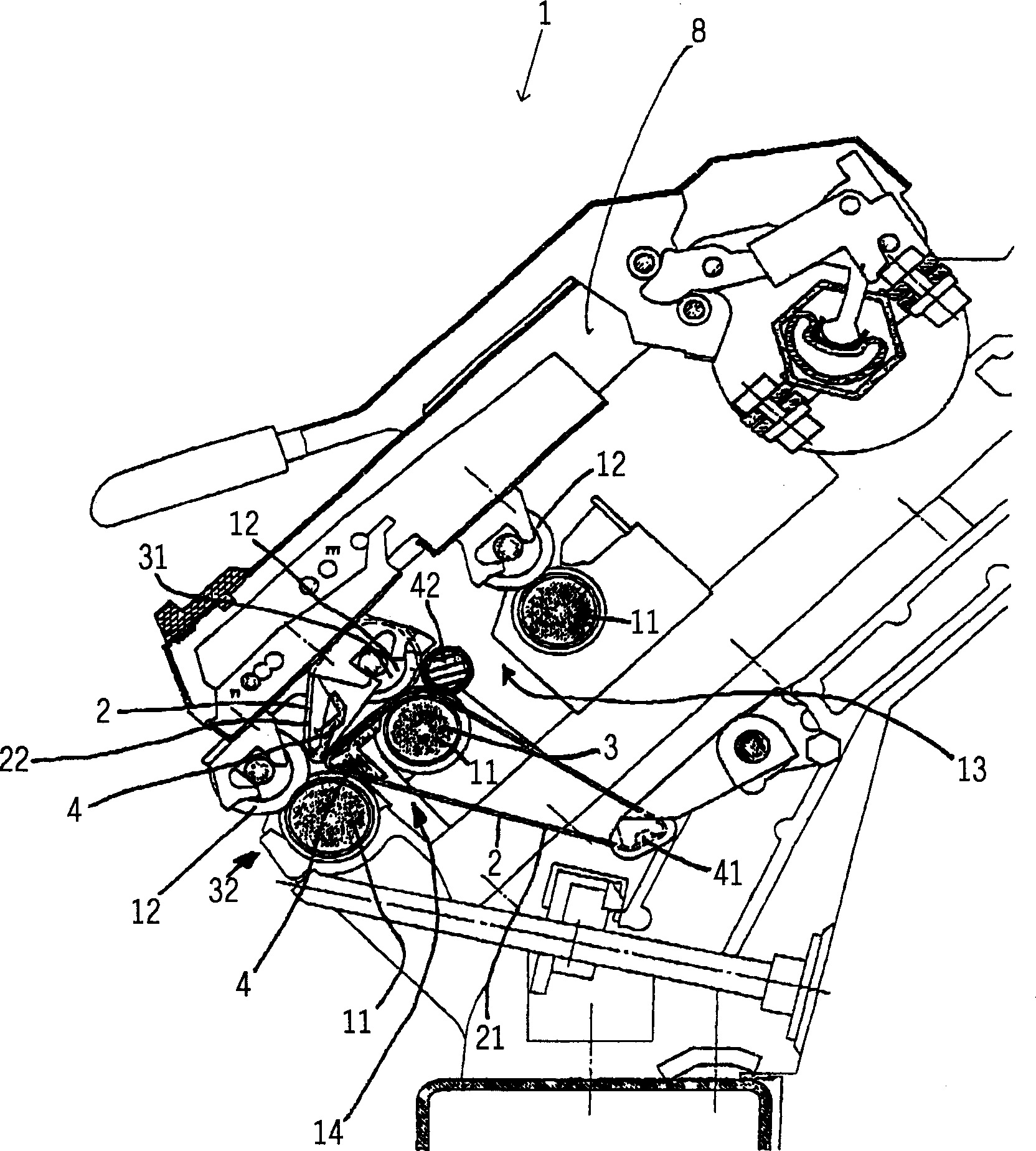

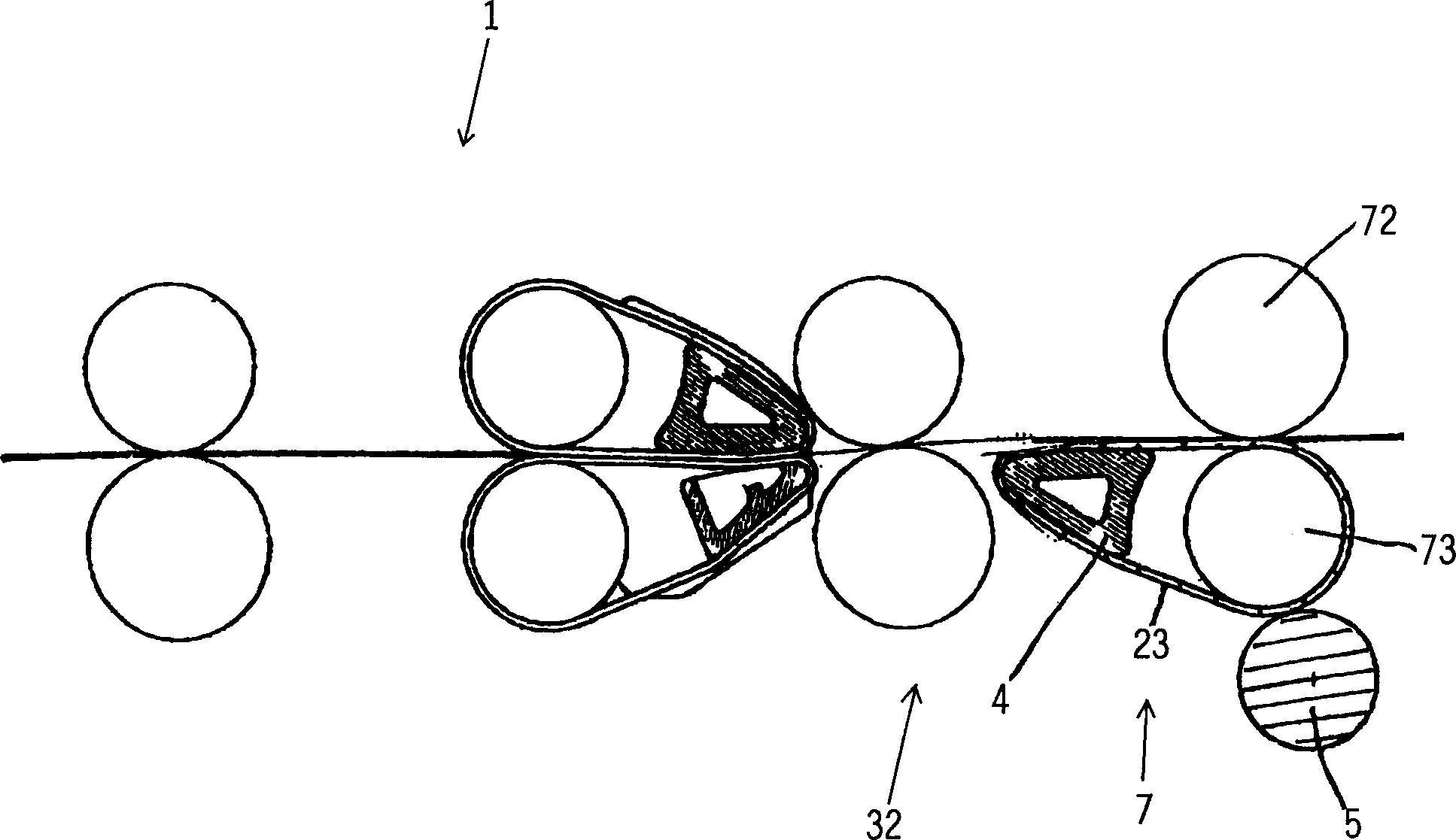

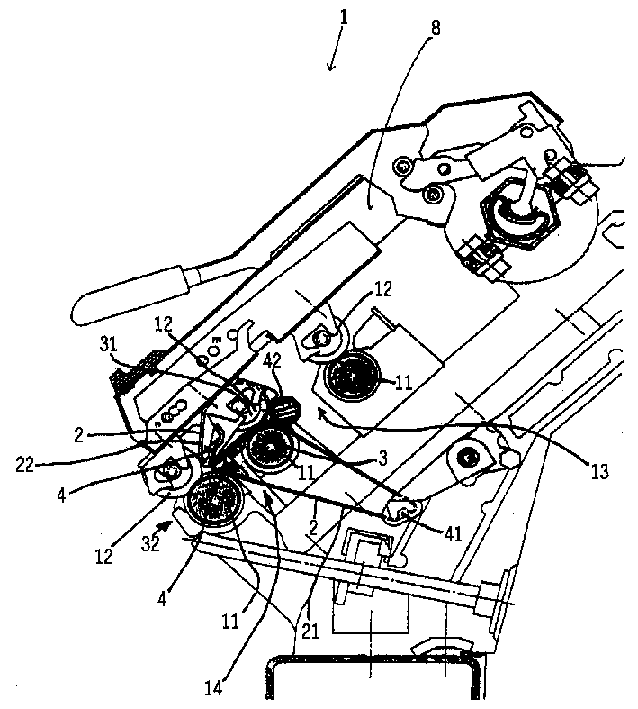

[0026] figure 1 A sectional view of the drafting device of the ring spinning machine of the present invention is shown. The drafting device 1 is a three-roller double-apron drafting device. The drafting device 1 comprises three driven bottom rollers 11 (Unterzylindern), on which three top rollers 12 (Oberwalzen) are mounted. The pre-drafting zone 13 is followed by a main drafting zone 14 in which two aprons 2 for guiding the fibers are arranged in the main drafting zone 14 for guiding the fibers. To this end, the middle roller 3 (Mittelzylinder) and the opposite top roller 31 (Oberwalze) are each wound by their aprons 21 , 22 , which are guided in the direction of the delivery roller pair 32 by means of the guide 4 . Two aprons 2 slide on the guide 4, and they are guided from the guide 4 by the middle roller 3 and the top roller 31 to the wedge-shaped gap of the output roller pair. The apron of top roller 31 is placed on the apron 2 of middle roller 3. The bottom apron 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com