Transfor platform capable of forming picture and text symbols and its producing method

A technology of symbols and graphics, applied in the transfer printing platform and its manufacturing field, can solve the problems of ambiguity, high viscosity, and unclear fonts of graphic symbols, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

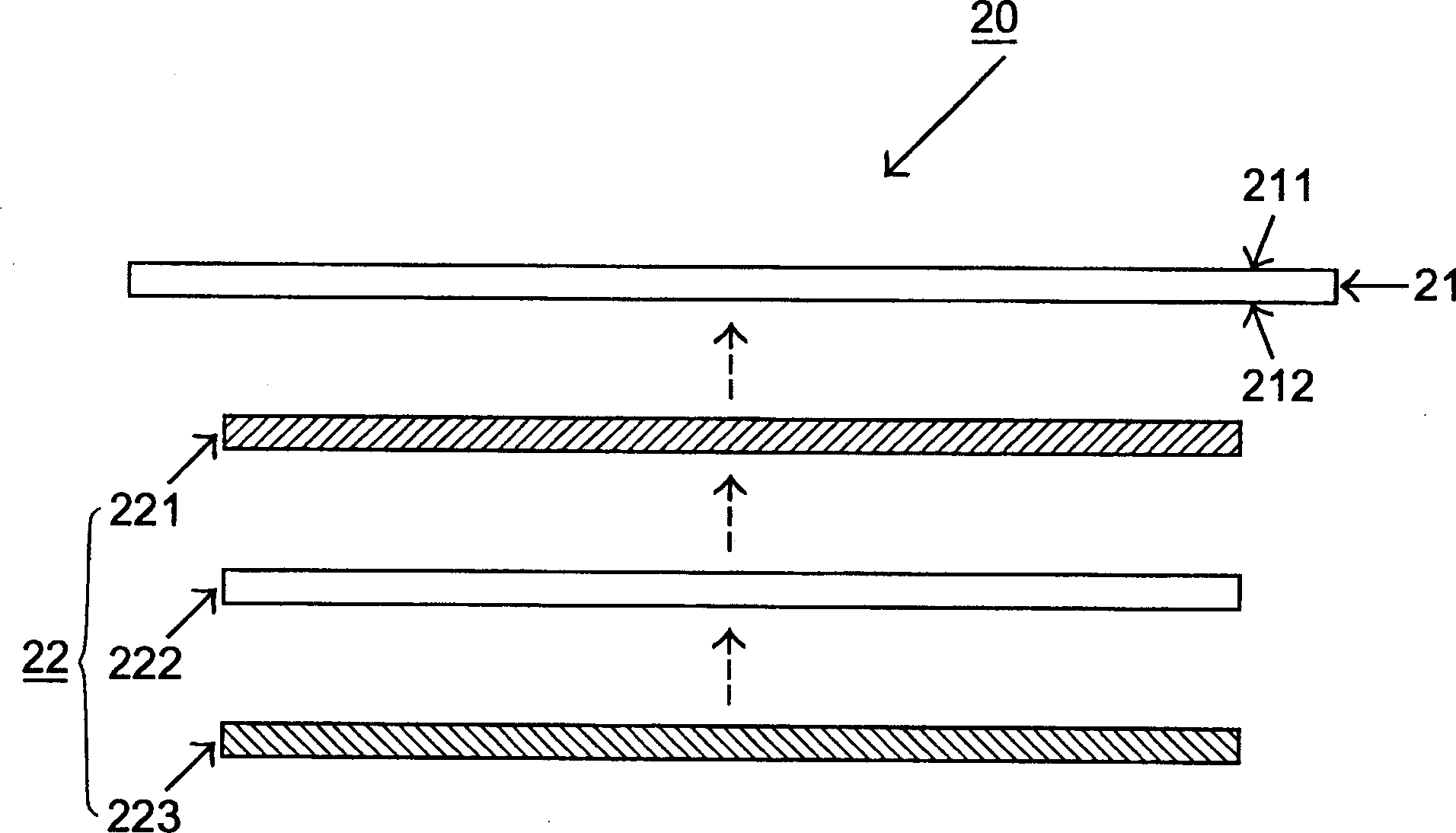

[0096] Please refer to FIG. 2( a ) and FIG. 2( b ), which are schematic diagrams of a side view and a top view of a first preferred transfer printing platform 20 shown in the present invention, respectively. Different from the known structure shown in Fig. 1 (a) and Fig. 1 (b), this first preferred transfer printing platform 20 shown in the present invention consists of a transparent sheet 21, an ink layer 221, a transparent viscous reducing The agent layer 222 and a sensing adhesive layer 223 are formed. Wherein, the transparent sheet 21 can be a transparent film of B.O.P.P. material, and the transparent sheet 21 also has a first and a second surface 211, 212 (for example, they can be upper and lower surfaces respectively). In addition, the ink layer 221 , the viscosity reducing agent layer 222 and the induction adhesive layer 223 are overlapped to form a transfer material 22 .

[0097] One of the characteristics of this embodiment is that the material type of the ink layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com