Fixed type constant-speed universal joint

A technology of constant velocity universal joints and internal components, which is applied to steering columns, steering controls installed on vehicles, and rotating parts that resist centrifugal force, etc., and can solve problems such as inability to rotate with freewheeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

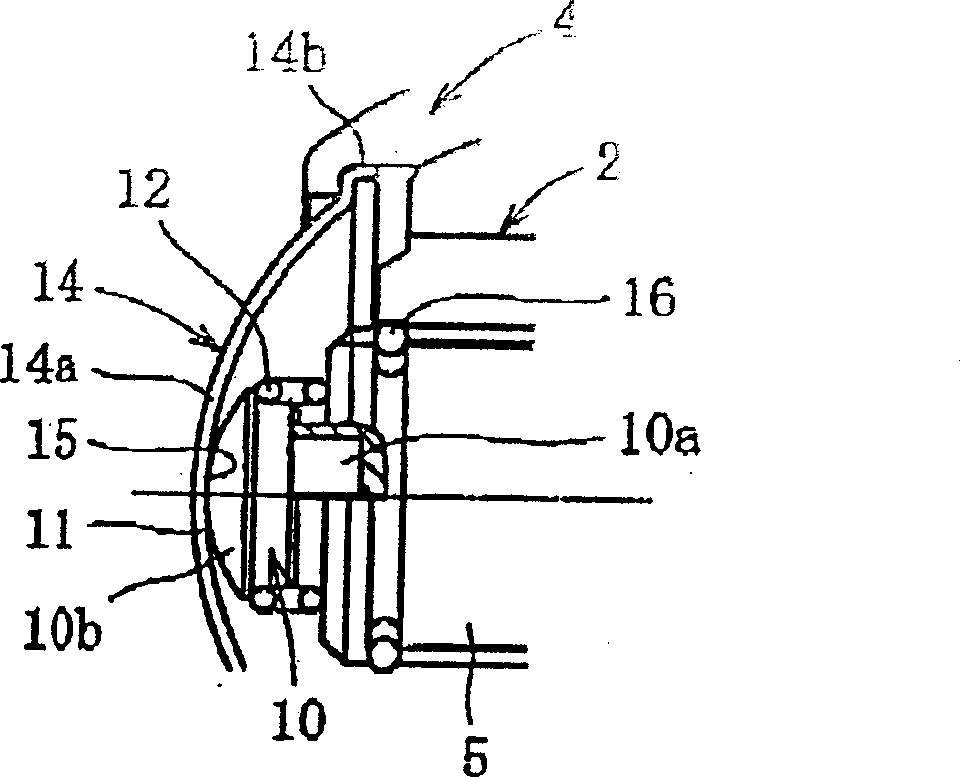

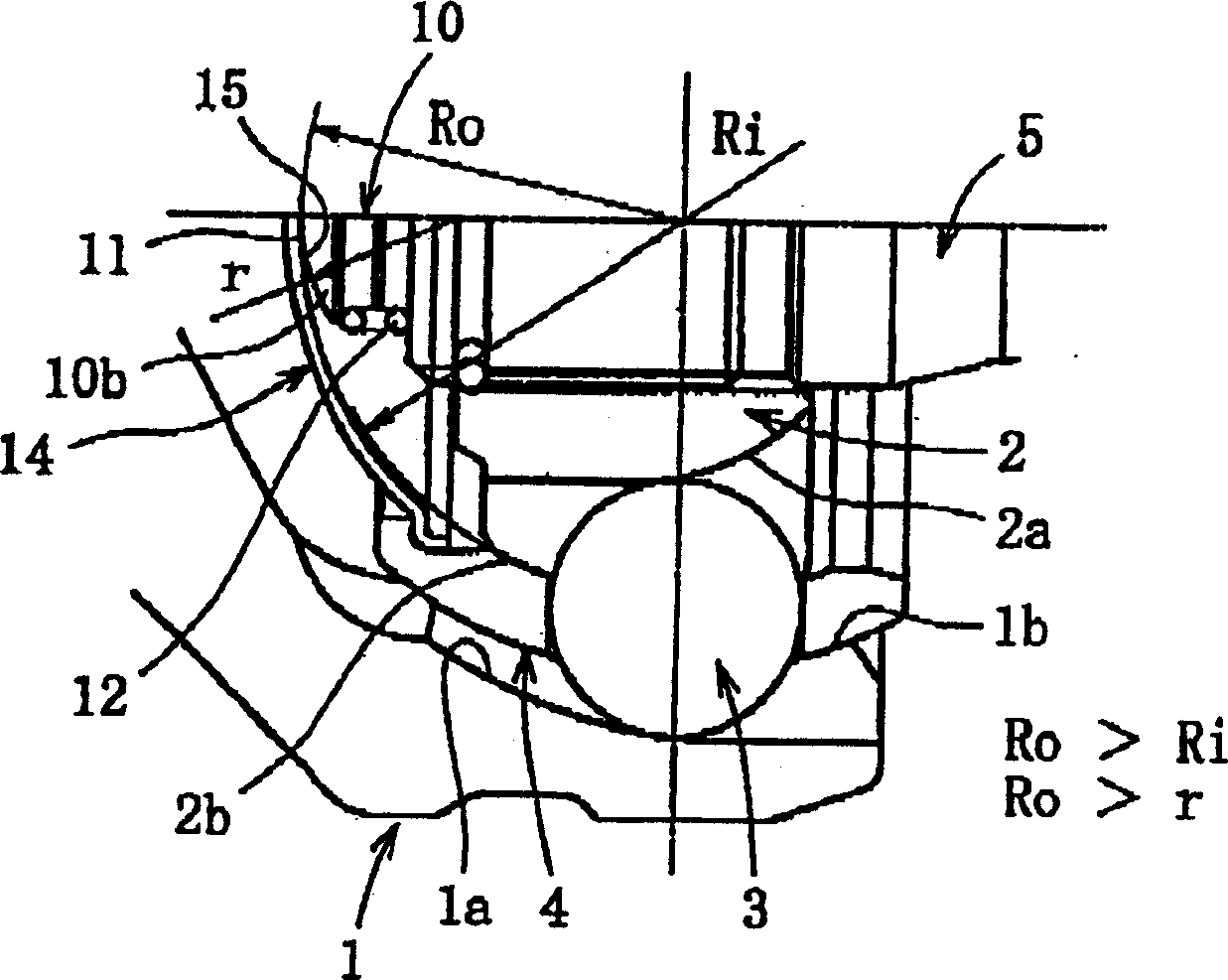

[0030] Below, according to Figure 1 to Figure 13 Embodiments of the present invention will be described.

[0031] Figure 1 to Figure 12 A case where the present invention is applied to an undercut type (UJ) which is a fixed type constant velocity universal joint is shown as an example.

[0032] like figure 1 As shown, the main structural elements of this type of constant velocity universal joint include: an outer wheel 1 as an outer member equipped with a spherical inner surface 1b forming a plurality of rail grooves 1a, and an outer wheel 1 equipped with a spherical outer surface 2b forming a plurality of rail grooves 2a Inner wheel 2, a plurality of balls 3 arranged in the ball track formed by the cooperation of the rail groove 1a of the outer wheel 1 and the rail groove 2a of the inner wheel 2 are arranged on the spherical inner surface 1b of the outer wheel 1 and the spherical outer surface of the inner wheel 2 The cages 4 between 2b have pockets for receiving balls 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com