Oil field visous crude sewage silicone-removing and cleaning process

A technology of heavy oil sewage and process technology, which is applied in the directions of water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. Strict requirements and other issues, to achieve the effect of simple process flow, good treatment effect and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

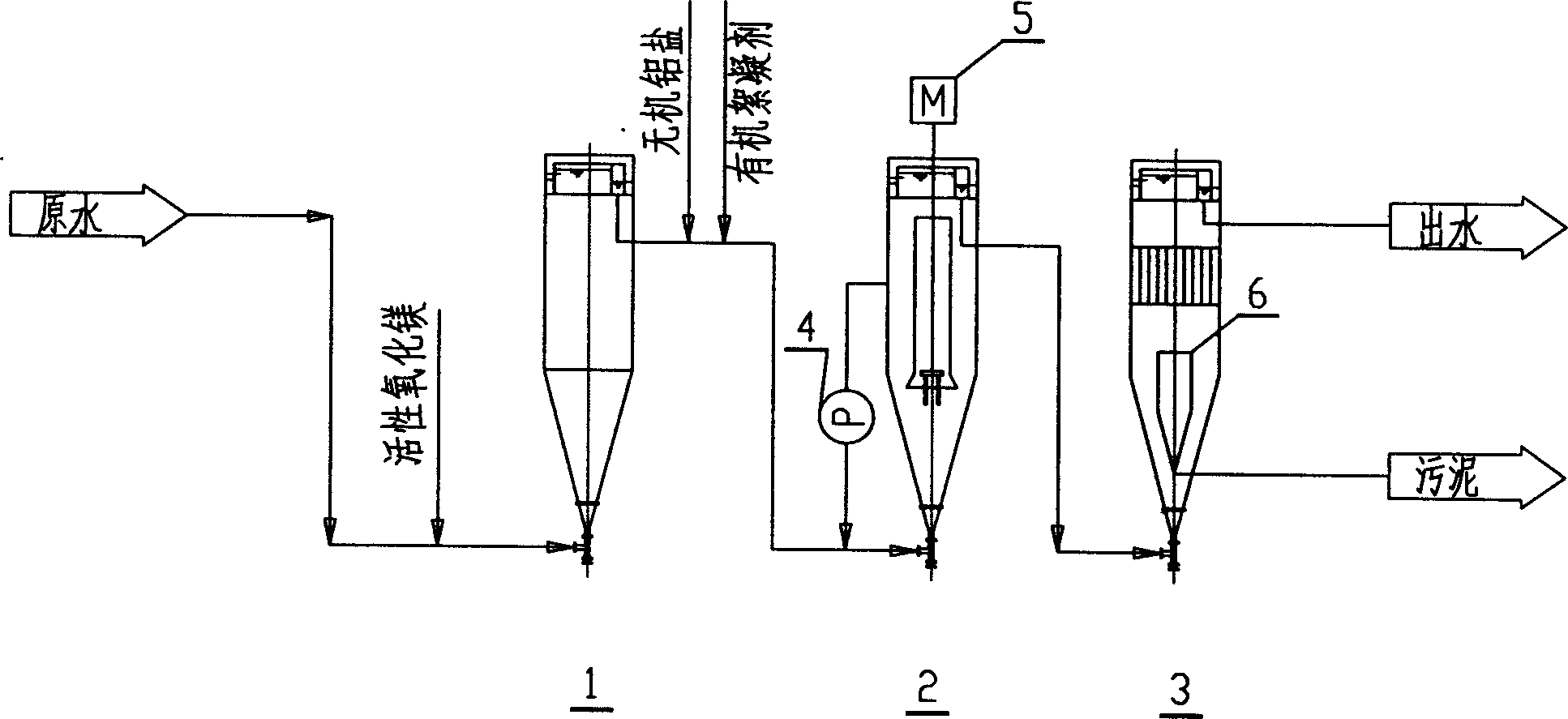

[0007] The implementation of the present invention will be described below in conjunction with the accompanying drawings. As shown in the figure, the process flow of the present invention consists of a vortex reactor 1, a sludge reactor 2, a sedimentation clarifier 3, a reflux pump 4, a stirring lifting device 5 and a sludge tank 6. The working process of silicon removal and water purification is as follows Completion: Add active magnesia with a content of 50-500mg / L to the pretreated heavy oil sewage (dosage is 1-3 times the amount of silicon dioxide removed), the activated magnesia is calcined by a special process, and can be obtained according to It needs to be made into 80-500 mesh fine particles with strong adsorption; add active magnesium oxide in sewage with higher temperature (40-70°C), quickly mix in vortex reactor 1, and evenly distribute in sewage. Magnesium oxide molecules on the surface of magnesium oxide particles react with water to form magnesium hydroxide at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com