Printing material generating black and white silver halides

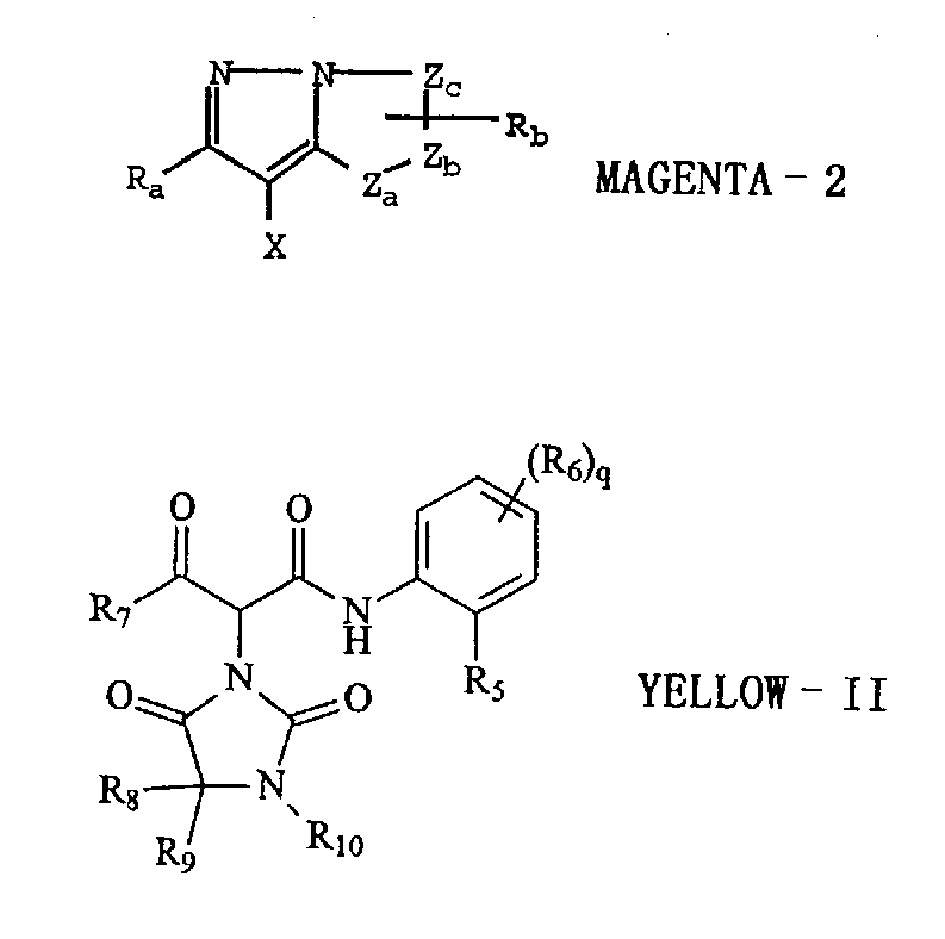

A photographic material and yellow dye technology, which is applied in the field of silver halide printing media for photography, can solve the problems of poor light stability of magenta dye, achieve the effect of improving thermal and light stability, and improving image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0204] The photo paper support was prepared as follows: a pulp furnish of 100% bleached hardwood kraft paper was refined through a double disc refiner followed by a Jordan conical refiner. To the resulting pulp furnish was added 0.8% sodium stearate, 0.5% aluminum chloride, 0.15% stilbene triazine FWA, 0.2% polyamide-epichlorohydrin, 0.7% anionic polyacrylamide and 0.6% titanium dioxide, all Ratios are based on dry weight. Total dry weight base paper of approximately 31.5 lbs per 1000 square feet (ksf) produced on a fourdrinier machine, wet processed to 42% solids, and dried with a steam heated dryer to 3% moisture content to an apparent density of 0.70 g / cc. The surface of the base paper substrate was sized with a 16% hydroxyethylated cornstarch solution by vertical pressing to achieve a starch loading of 4.2% by weight. The surface-sized support was dried to a moisture content of 8.8% using a steam-heated drier and calendered to an apparent density of 1.08 gm / cc.

[0205...

Embodiment 1

[0280] Example 1 of the present invention. The dispersion liquid of Example 1 of the present invention was prepared according to the method used in Comparative Example 1. At 140°C, couplers M-4, IC-27 and Y-5 were mixed in S-11 and S-9 (1 / .99wt / wt) at a weight ratio of 1.000 / 0.625 / 1.105, and mixed in gelatin aqueous solution emulsified to a final concentration of 7.4% by weight of gel, 18.18% by weight of oil and 9.97% by weight of joint coupler.

[0281] This dispersion was coated in the same multi-layer form as Comparative Example 4, except that the yellow coupler Y-5 was coated at 8.8 mg / square foot in layer 3 and 15.8 mg / square foot in layer 2. Coating, while in layer 1 was coated at 42.2 mg / square foot.

Embodiment 2

[0282] Example 2 of the present invention. The dispersion liquid of Example 2 of the present invention was prepared according to the method used in Comparative Example 1. At 140°C, couplers M-4, IC-27 and Y-4 were mixed in S-11 and S-9 (1 / .99wt / wt) at a weight ratio of 1.000 / 0.625 / 0.89, and mixed in gelatin aqueous solution emulsified to a final concentration of 7.4% by weight of gel, 18.18% by weight of oil and 9.97% by weight of joint coupler.

[0283] This dispersion was coated in the same multi-layer form as Comparative Example 4, except that the yellow coupler Y-4 was coated at 7.12 mg / square foot in layer 3 and 12.81 mg / square foot in layer 2. Coating, while in layer 1 was coated at 34.2 mg / square foot.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com