Optical cable laying and fiber distributing method for optical fiber to house

A fiber optic cable laying and branching technology, applied in the direction of fiber optic/cable installation, etc., can solve the problems of high cost and troublesome construction, and achieve the effect of fewer optical cables, simple construction and laying, and reduced cable consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

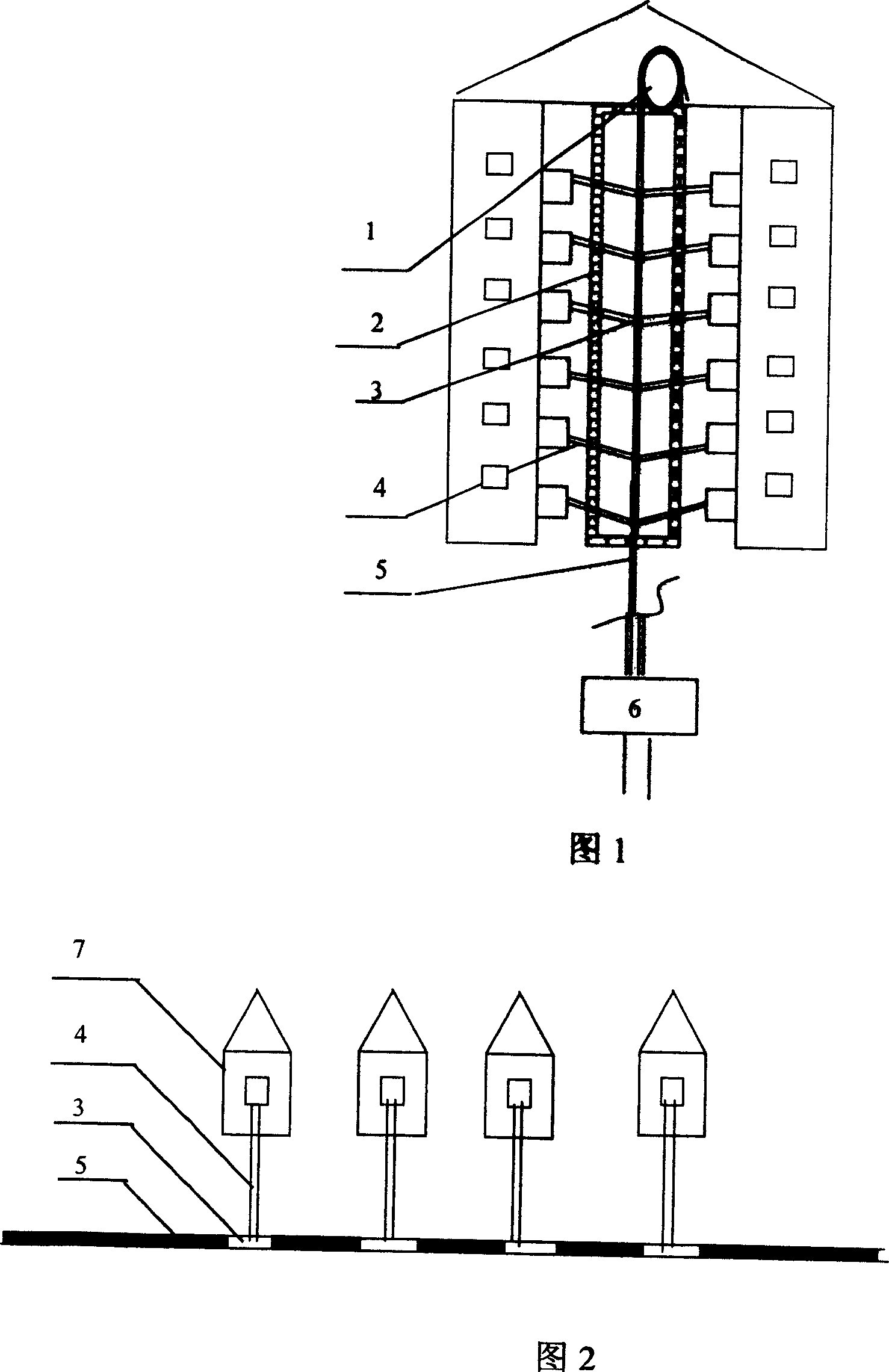

[0014] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0015] The first embodiment, as shown in Figures 1 and 3, is used for the access of the shaft corridor 2, and adopts a skeleton type optical fiber ribbon cable 5 with 3 to 9 fiber ribbon grooves, commonly used as 3, 5, 6 or 8 Skeleton optical fiber ribbon cable with a fiber ribbon slot, and a branch window 3 is set on each layer of the skeleton optical fiber ribbon cable. The axial length of the branch window is 40-70mm, that is, the outer sheath of the optical cable is completely stripped by 40-70mm to form a branch Window, from the cable core of the branch window, draw out the branched fiber ribbon 8 from the forward extension section, that is, each branch window cuts off the fiber ribbon that needs to be branched through the preceding branch window that extends forward, and draws it out from the branch window A length of optical fiber ribbon is used a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com