Flexible urethane foam and its production and material system used for it thereof

A technology of polyurethane foam and blowing agent, which is applied in the field of flexible polyurethane foam and its manufacture and the material system used for its manufacture, and can solve problems such as insufficient support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5 and comparative example 1-4

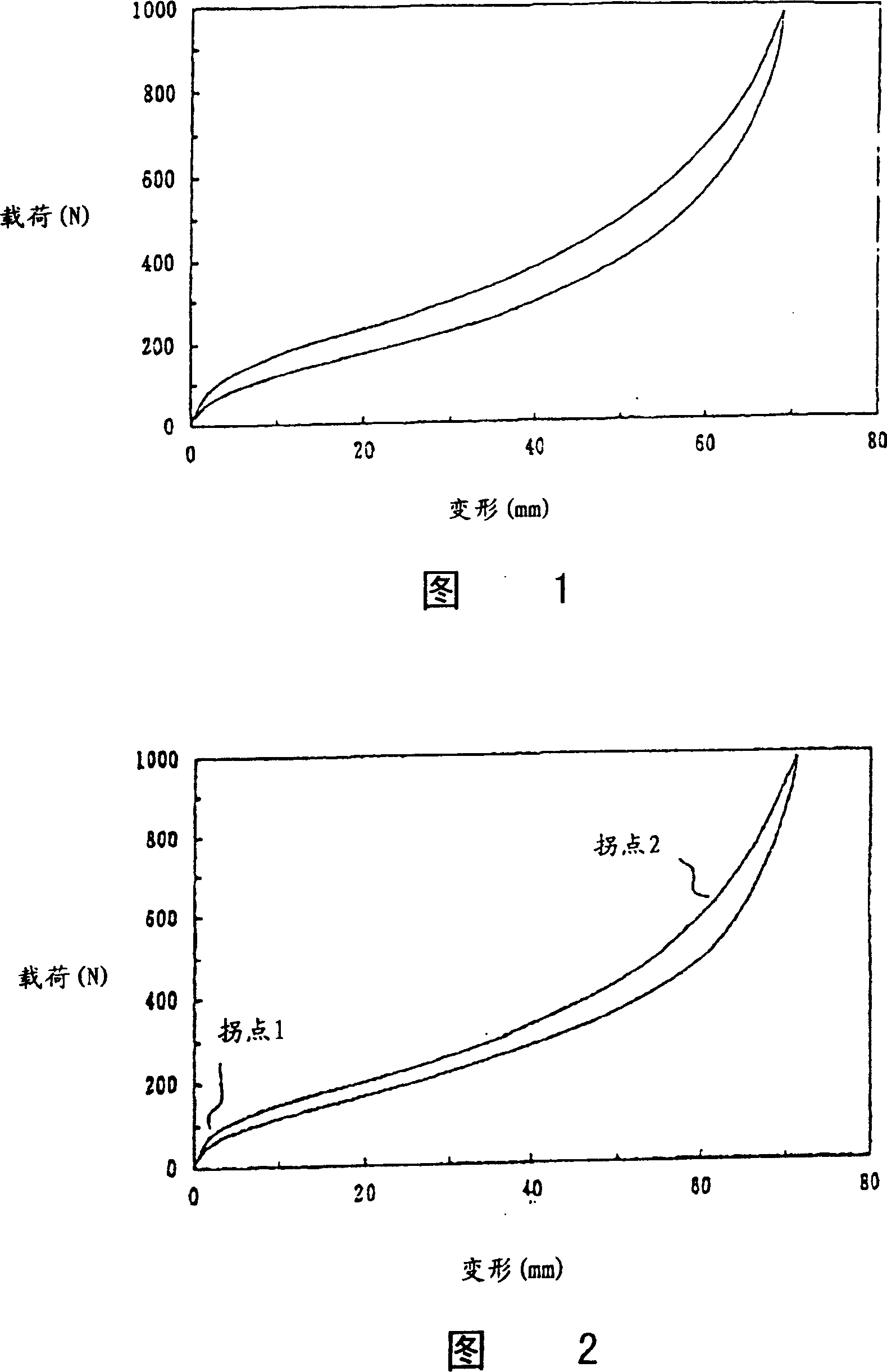

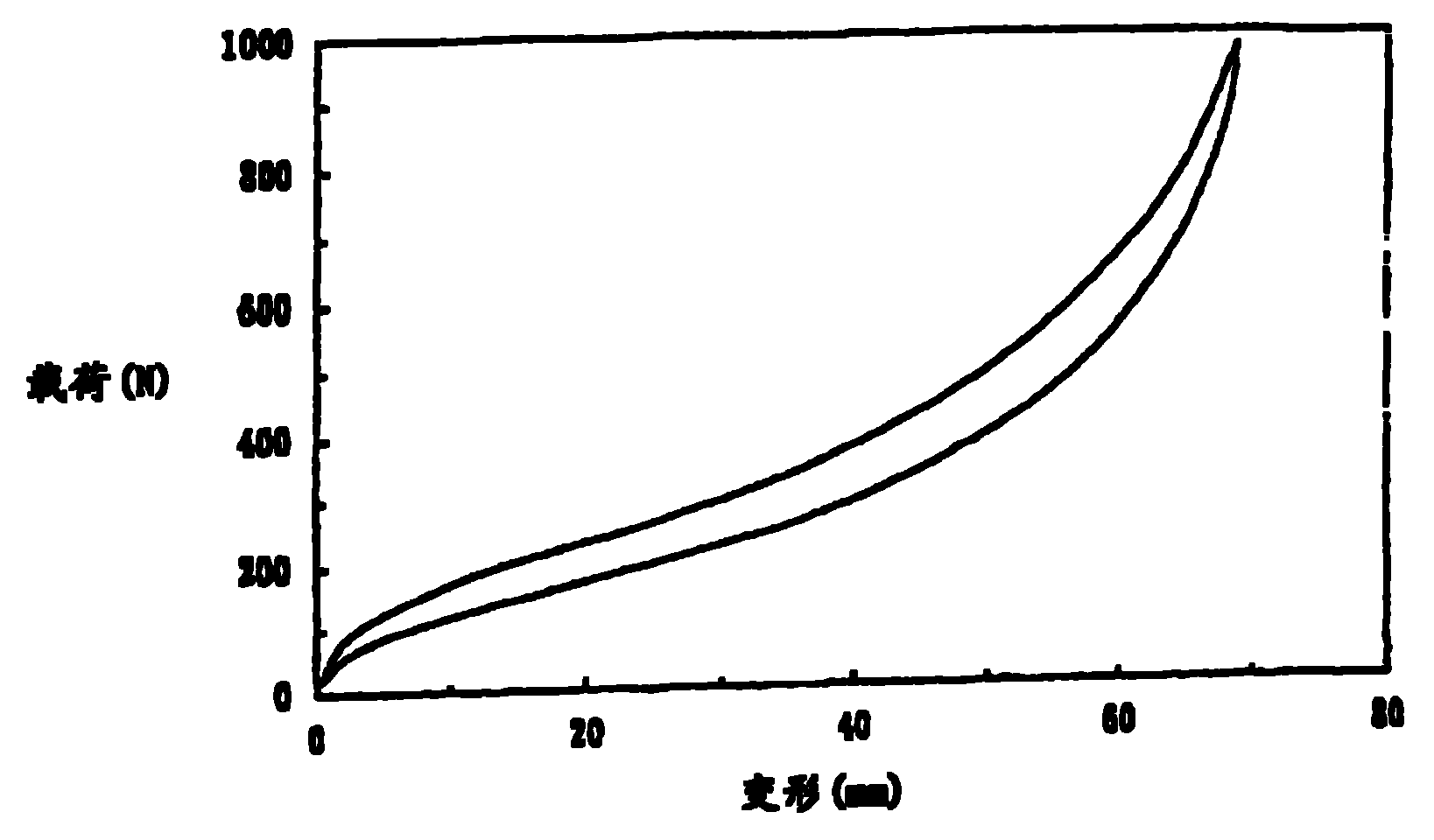

[0120] The flexible foam was produced by using the materials shown in Table 2 and the amounts of the materials shown in Table 3 (numbers indicate mass fractions). In these materials, the polyol-based liquid and the polyisocyanate compound are each adjusted to have a liquid temperature of 25±1°C, and a predetermined amount of the polyisocyanate compound is added to the polyol-based liquid, followed by mixing and stirring with a high-speed stirrer for 5 seconds , Immediately pour the mixture into an aluminum mold with a size of 400 mm in length, 400 mm in width and 100 mm in height, and heat to 60° C. After curing for 6 minutes, the flexible foam was removed and allowed to stand for at least 24 hours before various physical properties were measured. The measurement results are shown in Table 3. Here, the method of measuring the physical properties of the foam is according to the following methods: using a part cut into a size of 100 mm long, 100 mm wide, and 50 mm high, with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com