Double-screw fiberizer with tooth-shape disc

A twin-screw refiner and toothed disc technology, applied in the field of refiners, can solve problems such as difficult manufacturing, high operation and maintenance costs, and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

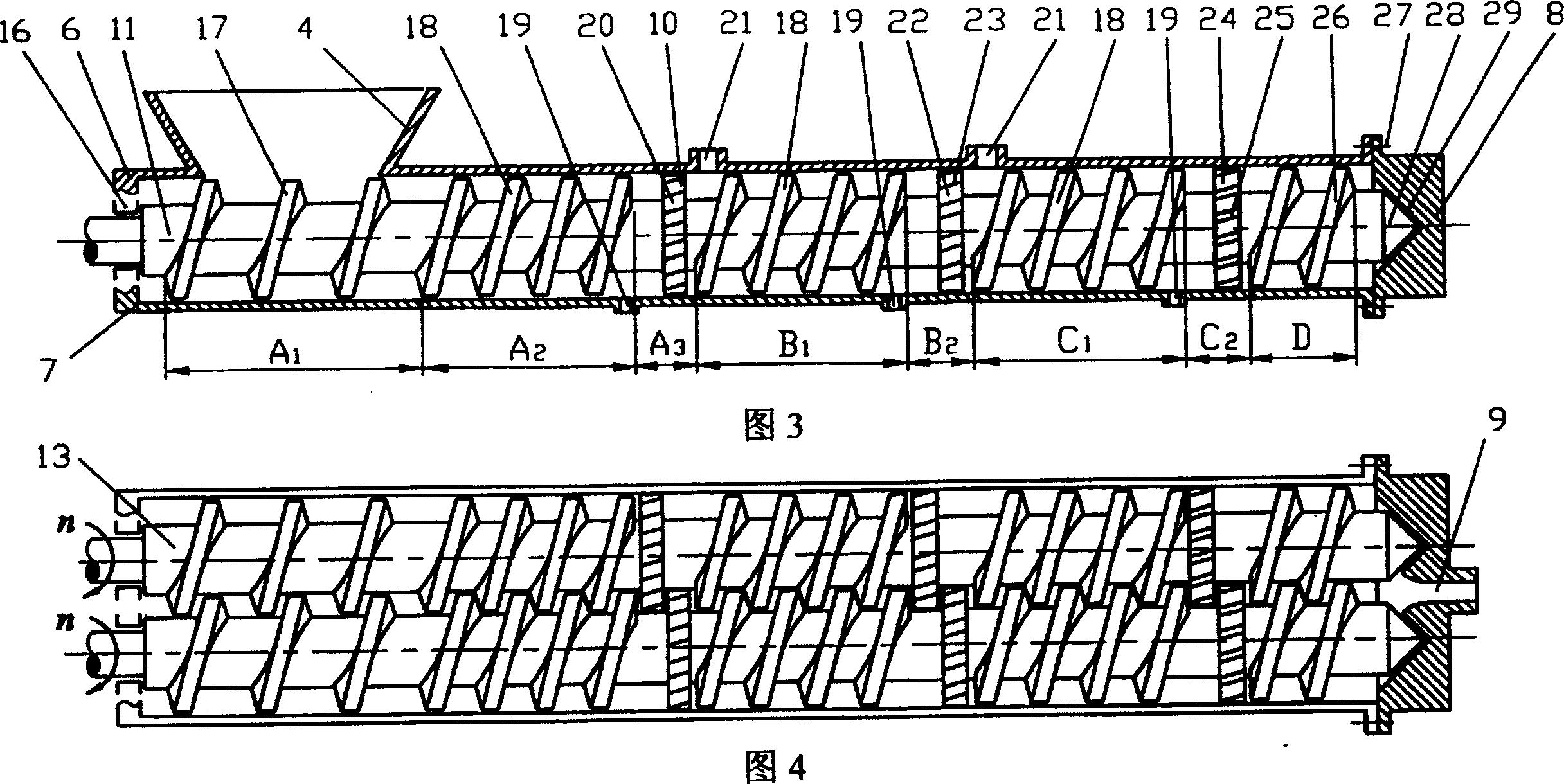

[0016] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

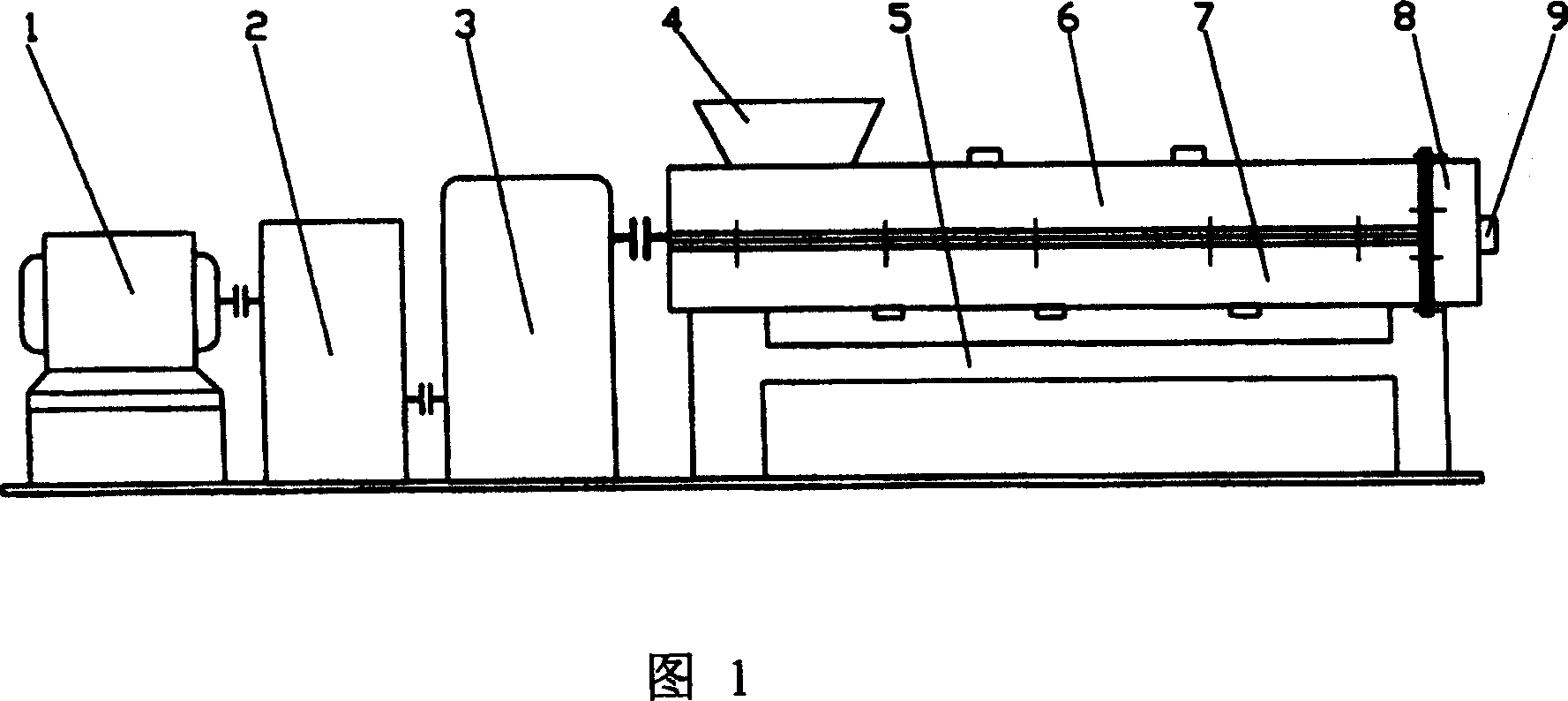

[0017] The toothed disc twin-screw refiner of the present invention shown in Fig. 1 is composed of a motor 1, a reducer 2, a power distribution box 3, a support 5, an upper casing 6, a lower casing 7, a head 8, and a feeding Port 4 and discharge port 9 are composed. The motor provides the power of the system, and provides torque to the mechanical device in the housing through the motor shaft, reducer and power distribution box. The bracket supports the upper and lower shells, the upper shell is provided with a material inlet, and the head is provided with a material outlet.

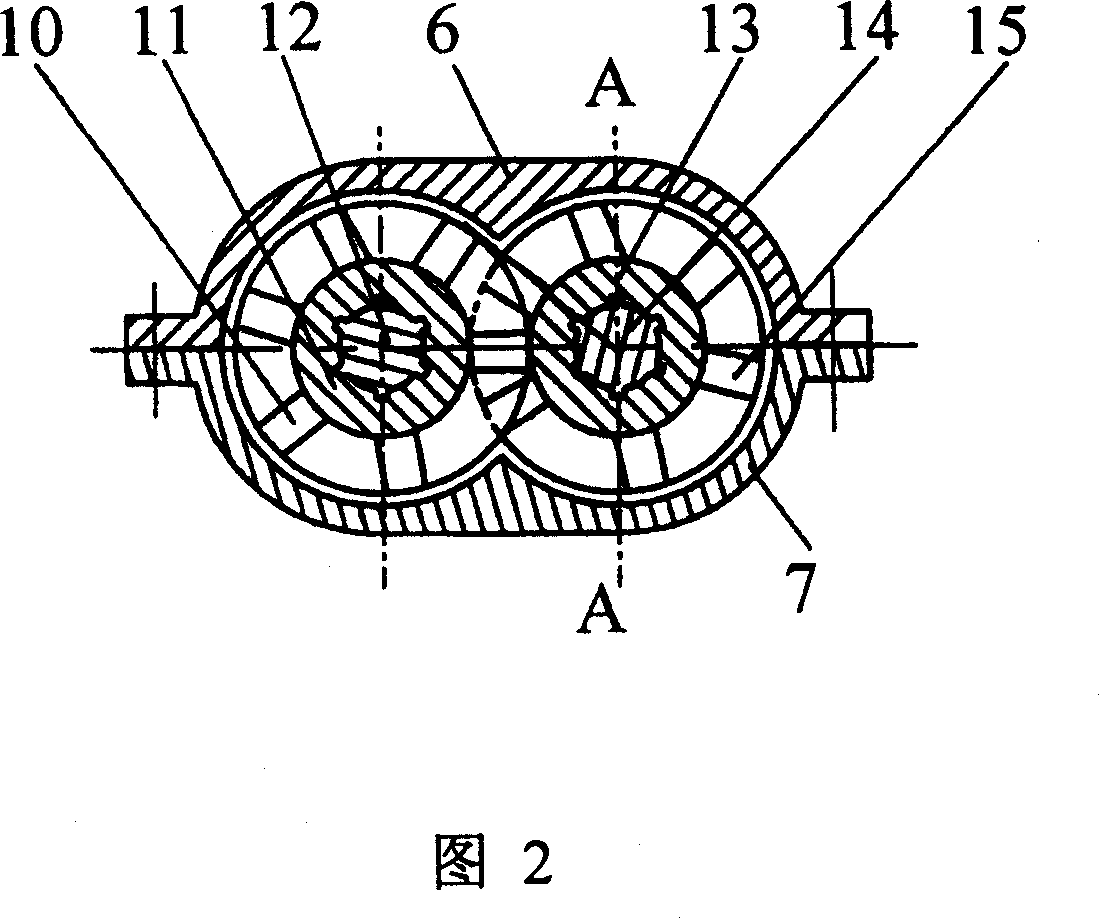

[0018] Figure 2 is a schematic cross-sectional view of the shell, in which the upper and lower shells are fixed by means of screws (unlabeled) and other fixing methods, and two parallel, threaded inner, Co-rotating screw rods 11 and 13 with equal outer diameters and intermes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com