Catalyst for selectively oxidizing tertiary butanol or isobutene to synthesize methyl acrylic aldehyde and its use

A technology for synthesizing methacrolein and selective oxidation, which is applied in the direction of physical/chemical process catalysts, preparation of organic compounds, preparation of carbon-based compounds, etc., and can solve the problems of shortening the service life of catalysts, deteriorating catalyst performance, reducing catalyst activity or selectivity And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

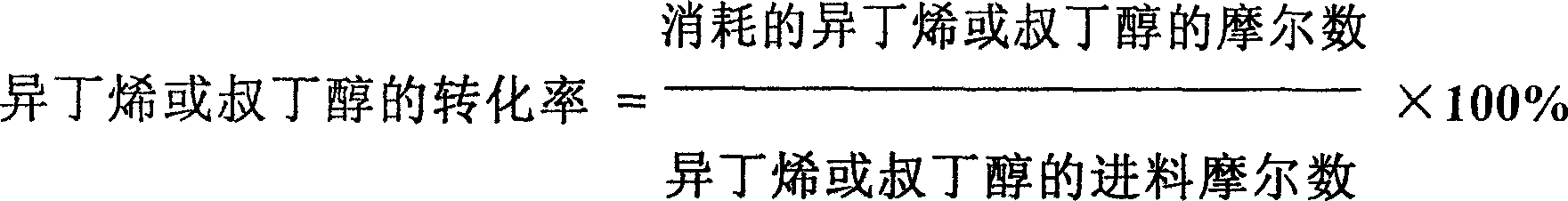

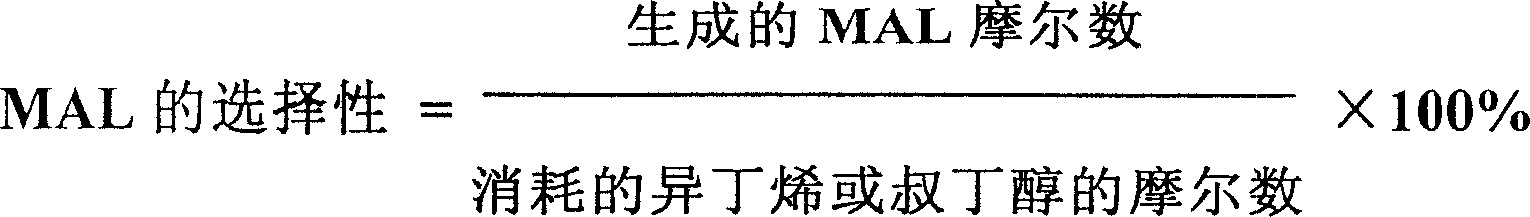

Method used

Image

Examples

Embodiment 1

[0018] One with 80 (Mo 12 Bi 1.8 Fe 2.0 co 7.0 Sb 0.3 Pb 0.2 Yb 0.1 W 0.5 sn 0.2 Cs 0.5 ) / 20TiO 2 The preparation method of the indicated catalyst (the atomic ratio of the metal elements constituting the active component and the carrier heat-conducting diluent) is as follows: 322.56 grams of ammonium paramolybdate and 21.58 grams of ammonium paratungstate are dissolved in 800 grams of distilled water at a temperature of 50°C to obtain a solution First. 122.22 grams of bismuth nitrate, 113.12 grams of ferric nitrate, 285.18 grams of cobalt nitrate, 9.38 grams of lead nitrate, 13.65 grams of cesium nitrate and 2.76 grams of ytterbium oxide were dissolved in 350 grams of 15% by weight dilute nitric acid aqueous solution to obtain solution B. 13.16 grams of antimony pentachloride and 6.30 grams of tin dichloride were dissolved in 30 grams of 10% by weight dilute hydrochloric acid aqueous solution to obtain solution C. Add solutions B and C to solution A respectively und...

Embodiment 2

[0021] In addition to using 8.19 grams of ammonium metavanadate and 8.33 grams of zinc nitrate to replace 21.58 grams of ammonium paratungstate and 6.30 grams of tin dichloride, 20 grams of nano-metal titanium powder was used to replace 20 grams of TiO 2 , and all the other are prepared catalysts by the same method as in Example 1. The catalyst consists of:

[0022] 80 (Mo 12 Bi 1.8 Fe 2.0 co 7.0 Sb 0.3 Pb0.2 Yb 0.1 V 0.5 Zn 0.2 Cs 0.5 ) / 20Ti

[0023] According to the same method as in Example 1, the catalyst was used for oxidation reaction at 398°C (hot spot). The conversion of isobutene was 96.2%, the selectivity of MAL was 86.7%, the selectivity of MAA was 2.1%, and the total yield of MAL and MAA was 85.4%.

Embodiment 3

[0025] In addition to replacing 21.58 grams of ammonium paratungstate with 9.31 grams of niobium pentoxide, 20 grams of SiC was used to replace 20 grams of TiO during molding. 2 , and all the other are prepared catalysts by the same method as in Example 1. The catalyst consists of:

[0026] 80 (Mo 12 Bi 1.8 Fe 2.0 co 7.0 Sb 0.3 Pb 0.2 Yb 0.1 Nb 0.5 sn 0.2 Cs 0.5 ) / 20SiC

[0027] According to the same method as in Example 1, the catalyst was used for oxidation reaction at 395° C. (hot spot). The conversion of isobutene was 94.9%, the selectivity of MAL was 89.8%, the selectivity of MAA was 1.2%, and the total yield of MAL and MAA was 86.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com