Single spindle drive type twisting frame

A driving type processing machine technology, which is applied in the field of twisting processing machines, can solve problems such as misjudgment of difficult-to-drive motors, and achieve the effect of accurate end-break judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

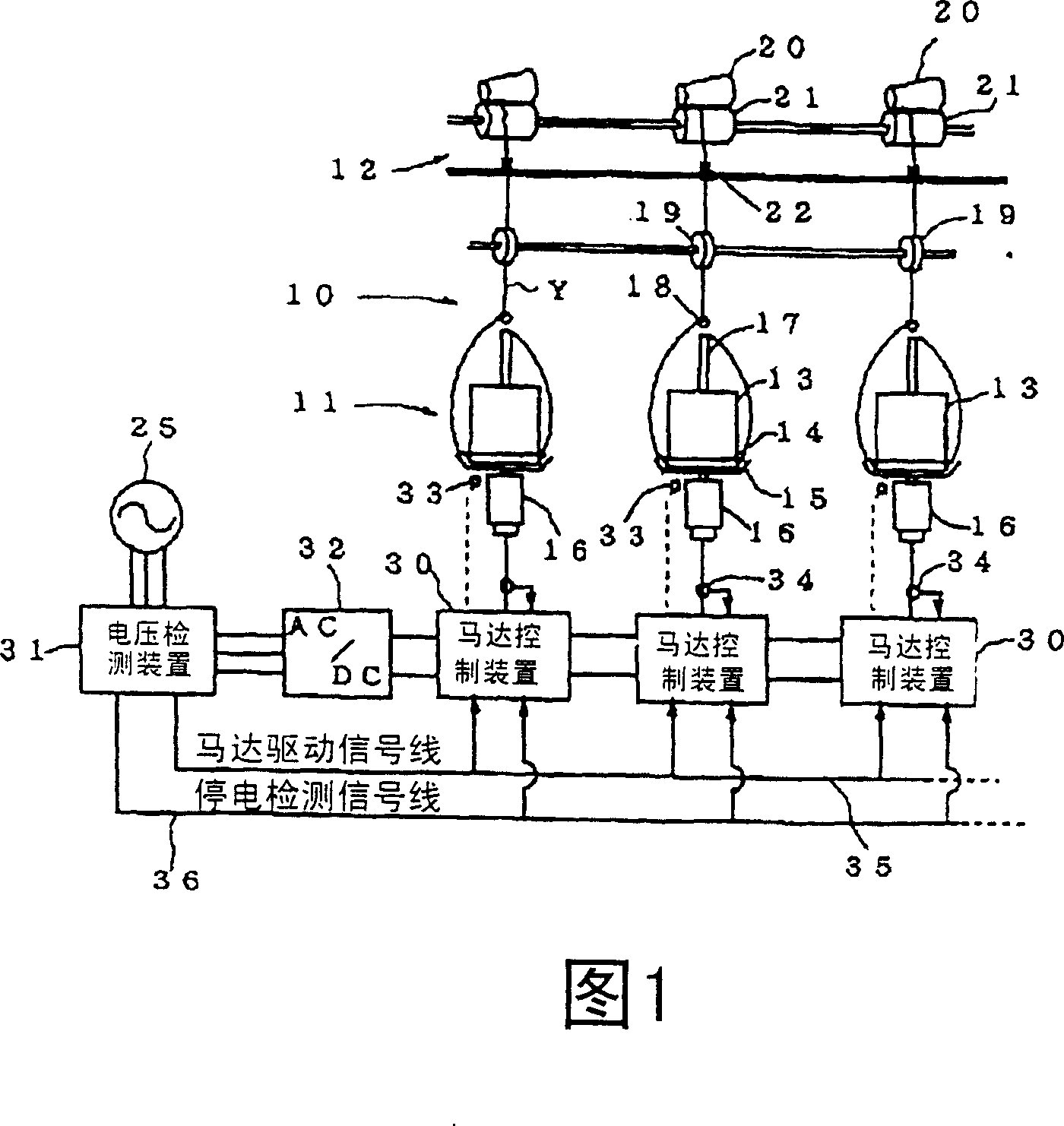

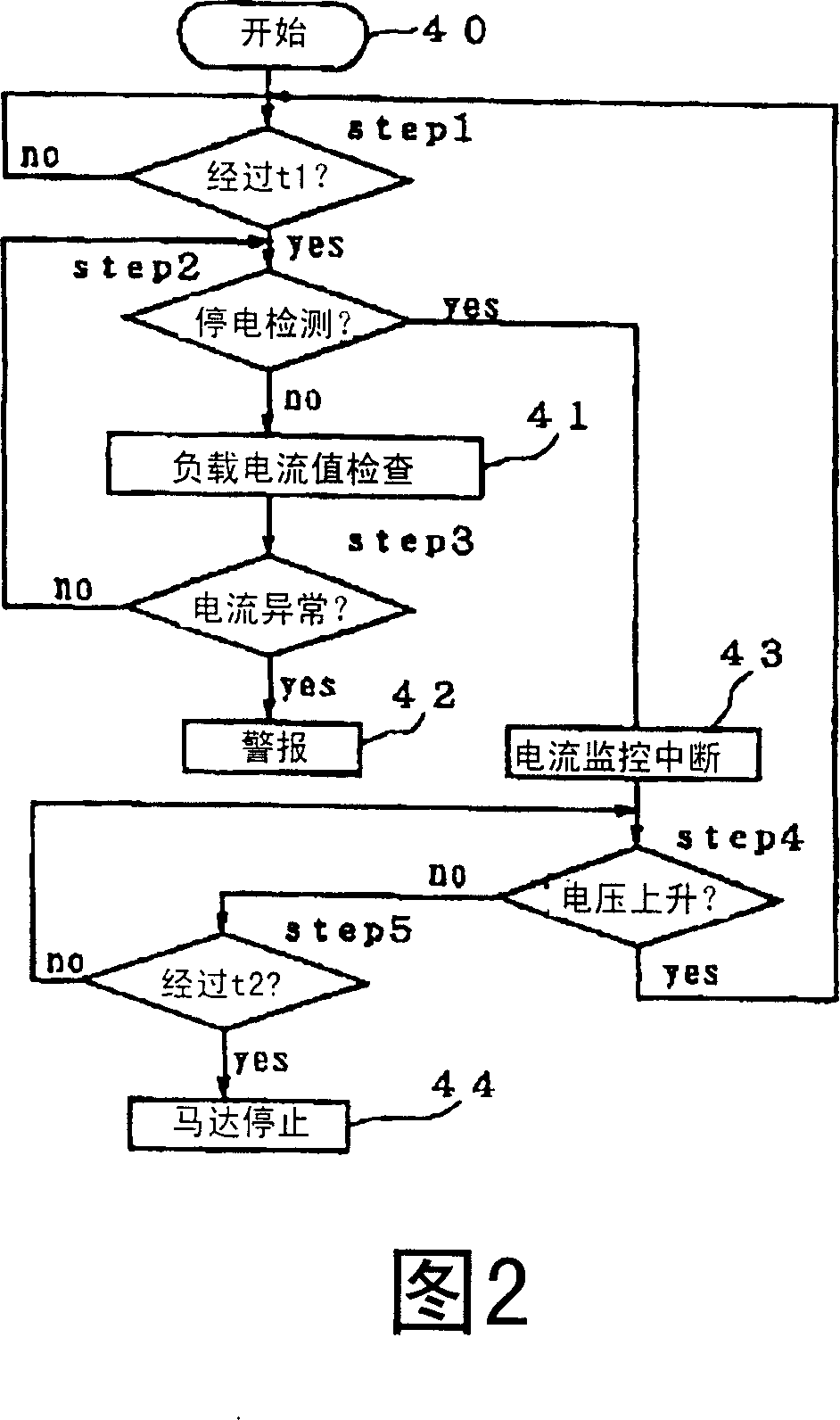

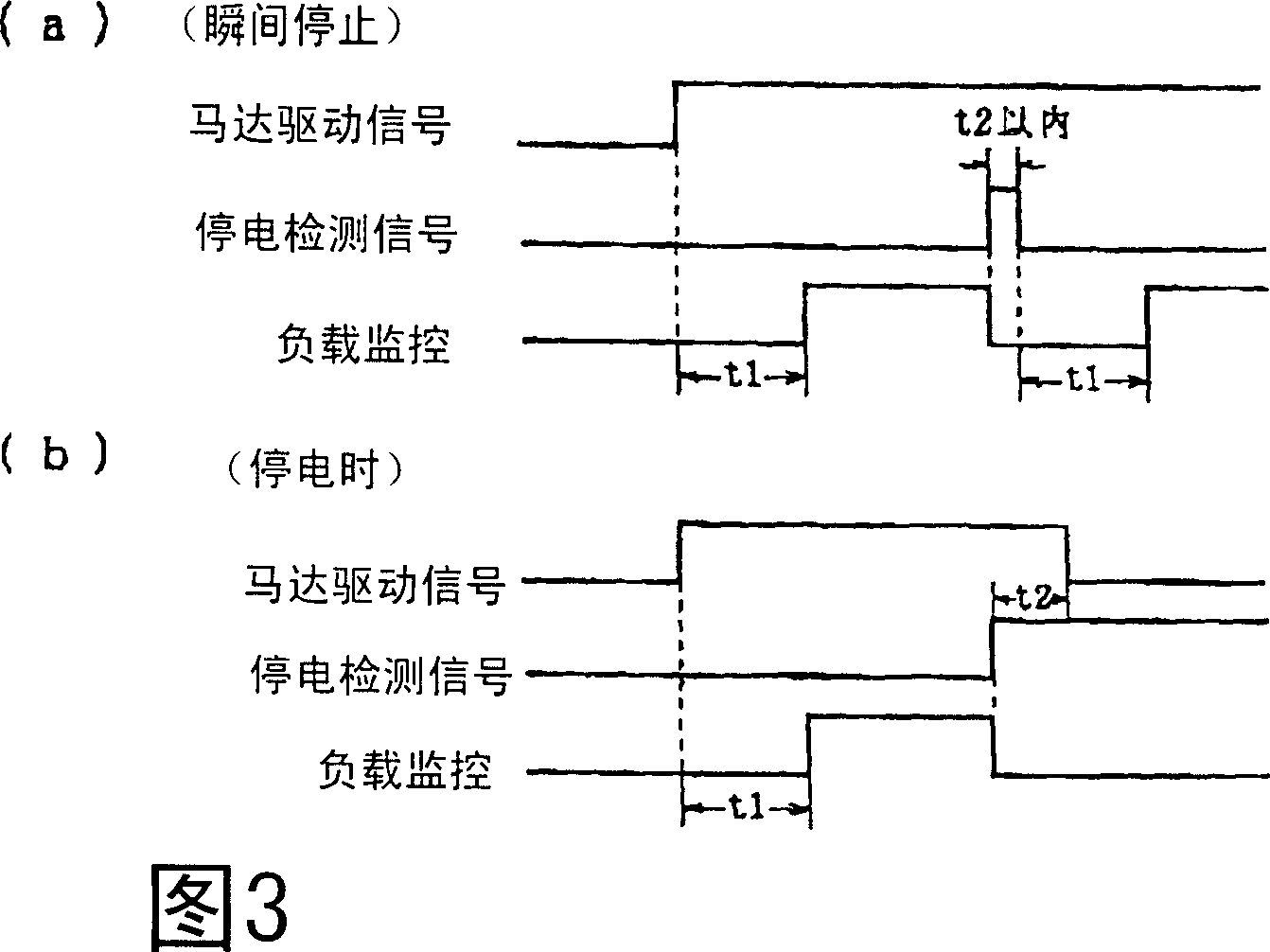

[0026] As shown in FIG. 1, the two-for-one twisting machine adopts a structure in which the twisting device 10 is arranged into a plurality of spindles, and the twisting device 10 is provided with a winding device 12 above the spindle device 11.

[0027] The spindle device 11 has: a fixed disk 14 for supporting the yarn feeding package 13, a rotating disk 15 arranged at the bottom of the fixed disk 14 to twist the yarn feeding, a drive motor 16 for rotating the rotating disk 15, and a rotating disk 16 installed on the yarn feeding The tensioner 17 at the axial center position of the package 13 and the balloon yarn guide 18 arranged on the extension line of the axial center of the yarn feeding package 13 . The winding device 12 has: a feed roller 19 for feeding the yarn Y from the balloon yarn guide 18; a drum 21 for rotating the winding package 20; The traversing device 22 for yarn feeding Y traversing.

[0028] While the yarn of the yarn feeding package 13 supported on the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com