Standing wave type ultrasonic vibration precision feeding device

A technology of ultrasonic vibration and feeding device, which is applied in vibrating conveyors, transportation and packaging, conveyors, etc., can solve the problems of travelling wave attenuation restrictions, uneven distribution, etc., and achieve diversified structures and uniform conveying speeds , easy to design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

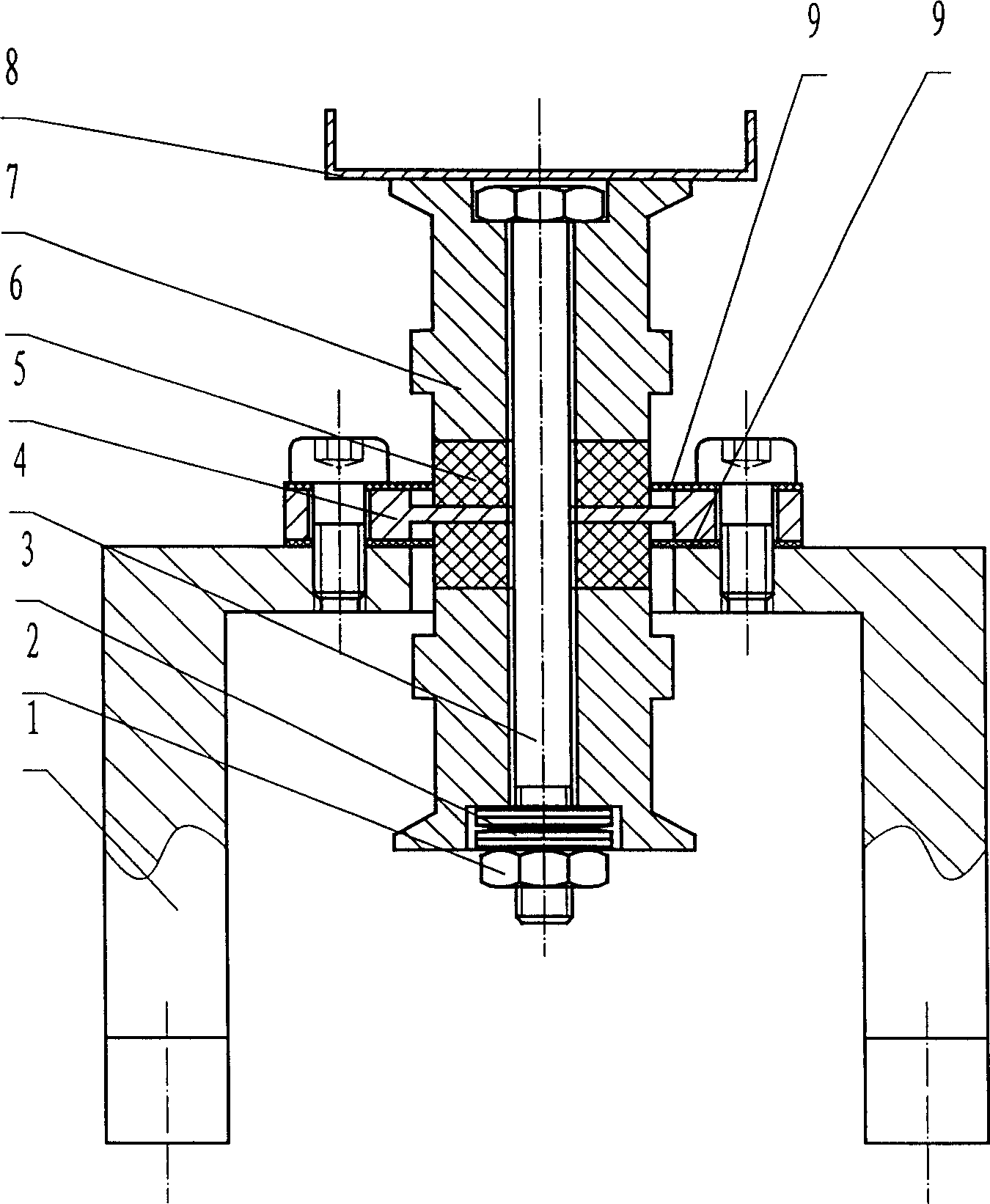

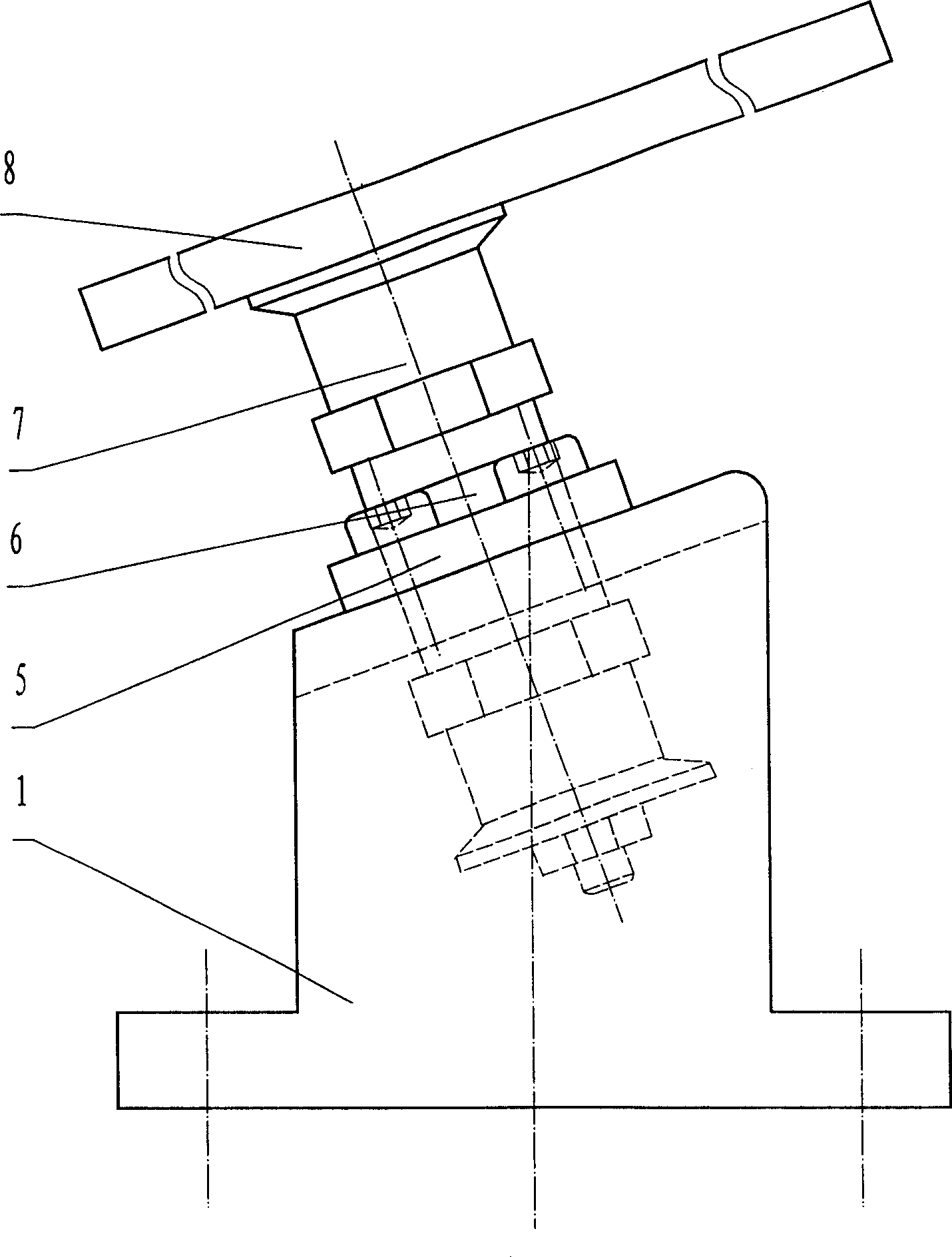

[0026] Such as figure 1 and figure 2 As shown, the present invention adopts the Langevin piezoelectric vibrator as the exciter, and the Langevin piezoelectric vibrator is a commonly used component in the field of ultrasonic vibration technology, and it is composed of a piezoelectric ceramic ring 6 and a metal elastic body 7; This embodiment adopts a Langevin piezoelectric vibrator, and there are two piezoelectric ceramic rings 6 on the Langevin piezoelectric vibrator, and bolts 4, nuts 2 and elastic washers 3 are used to connect the piezoelectric ceramic ring 6 and the metal 7 are fixed together; the two piezoelectric ceramic rings 6 are connected to the driving circuit through the copper sheet 5, and the voltage frequency of the driving circuit is 20kHz~100kHz, which is an existing common driving circuit; the Langevin piezoelectric vibrator is passed through the copper The piece 5 is fixed on the base 1, and the copper piece 5 is installed between two piezoelectric ceramic...

Embodiment 2

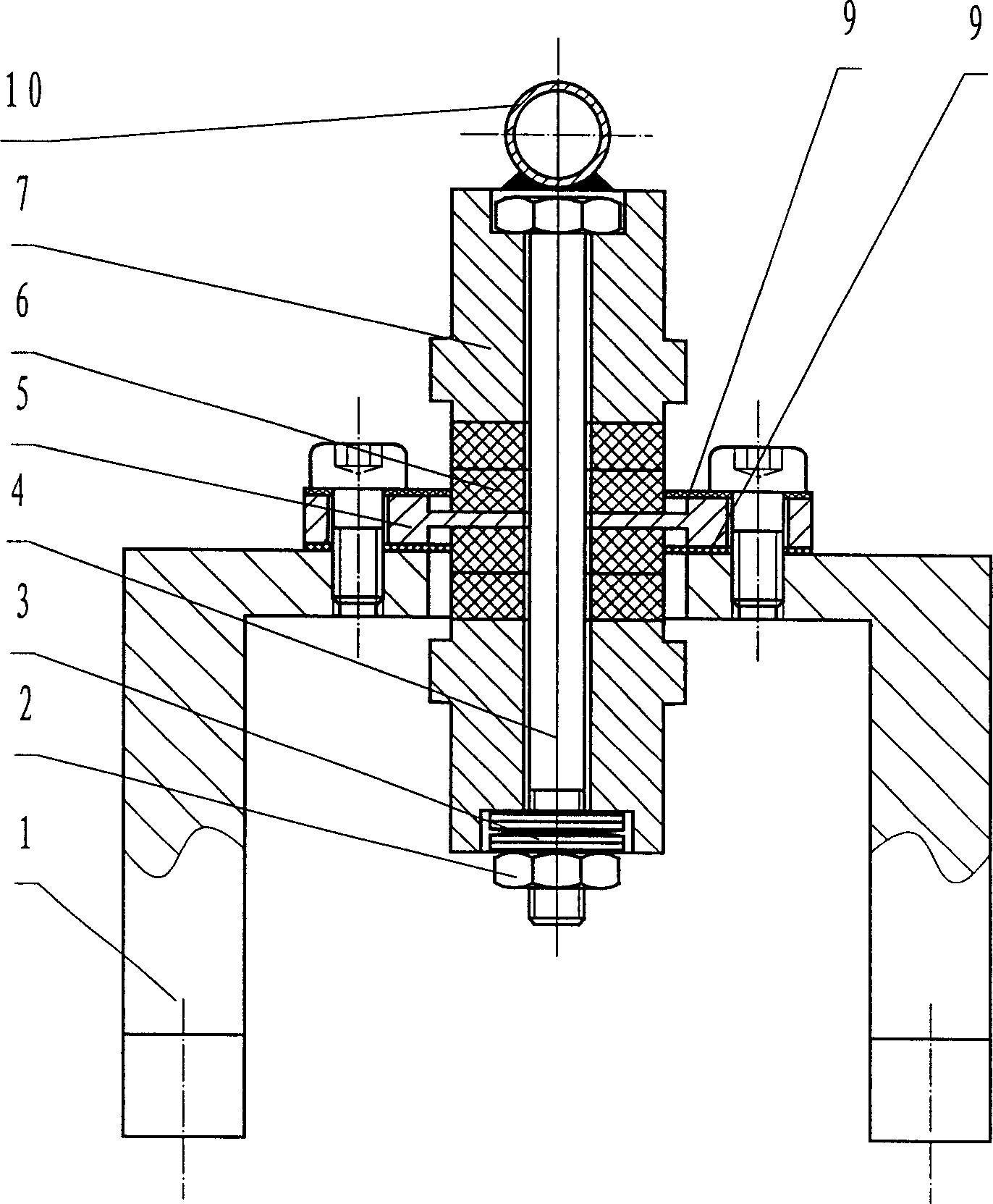

[0028] Such as image 3 As shown, its structure is as embodiment 1, and the difference is that the cross-sectional shape of the material conveying body 10 is a circular tube shape, that is, the material conveying body 10 is a tubular body, so as to transport materials in a closed state; the material conveying body 10 It is also possible to use tubes with cross-sections of other shapes, such as rectangular or elliptical, etc.; in this embodiment, the number of piezoelectric ceramic rings 6 of the Langevin piezoelectric vibrator is four, compared with two piezoelectric ceramic rings 6 provides more power. The piezoelectric ceramic ring 6 is fixed between two metal elastic bodies 7 with bolts 4, nuts 2 and elastic washers 3, and is located on both sides of the copper sheet 5. The vibration mode of the vibrator is the same as that of The vibration mode of the vibrator in Example 1 is the same, which is the first-order longitudinal stretching vibration of a bar with free ends.

Embodiment 3

[0030] As shown in Figure 4, its structure is the same as in Embodiment 1. The difference is that the Langevin piezoelectric vibrators are arranged in parallel along the conveying direction three times, and two, four or more can also be arranged in actual use. Multiple, determined according to the distance of material conveying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com