Main shaft motor

A technology of spindle motor and motor, applied in the direction of casing/housing/support, instrument, recording information storage, etc., can solve the problems of resin cracking, loose installation, large difference in thermal expansion rate of resin and metal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

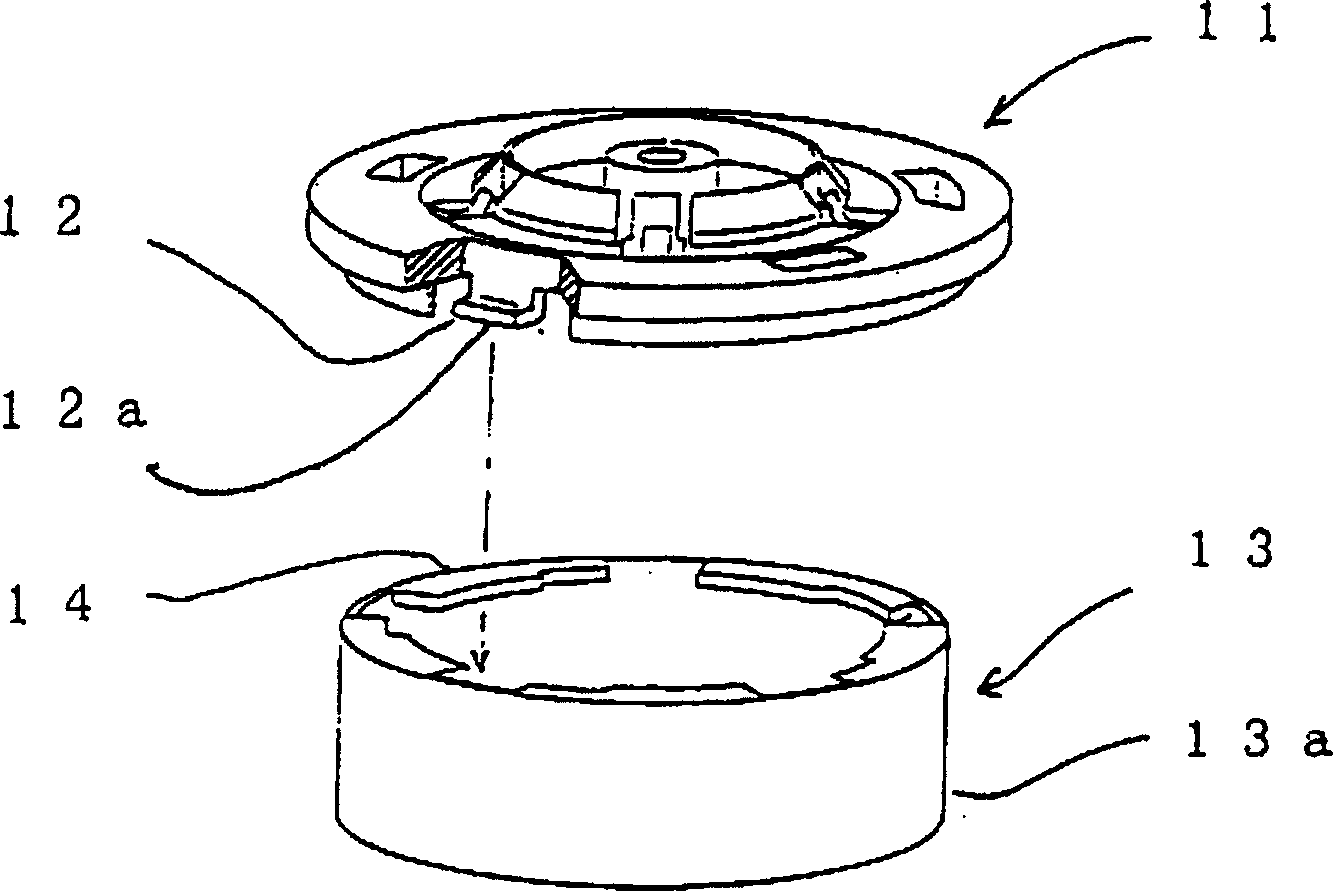

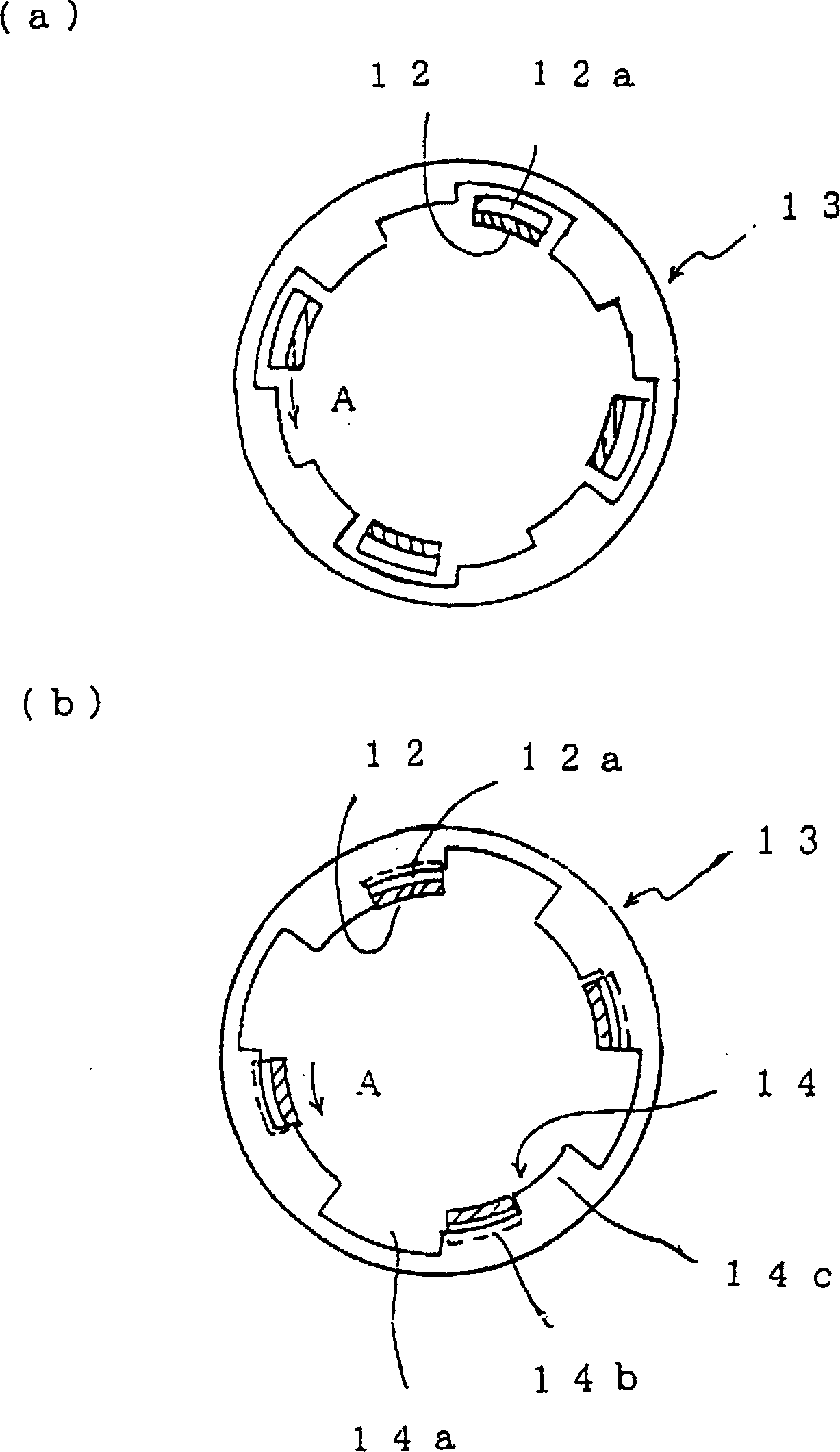

[0014] Hereinafter, a first embodiment of the present invention will be described in detail with reference to the drawings. figure 1 It is an exploded perspective view showing the main part of the first embodiment of the present invention. figure 2 (a), (b) means to put figure 1 Schematic diagram of the configuration in which the turntable is fixed to the motor housing.

[0015] exist Figure 1 ~ Figure 2 Among them, 11 is a turntable of the spindle motor, and 12 is an elastic claw for fixing, and in this embodiment, an example in which four are arranged at approximately 90-degree intervals is shown. But if there are more than 2, they can be properly arranged. 12a is a front end portion of the claw, which is formed by bending the front end of the fixing claw 12 outward in a substantially L-shape. Reference numeral 13 denotes a motor housing, which has a short cylindrical tube portion 13 a and a flange-shaped fitting portion 14 extending from one end of the tube portion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com