Aerosol can

A technology of spray cans and spray heads, which is applied in the direction of spraying devices, liquid distribution, application, etc., can solve problems such as sudden spraying, and achieve the effect of high fixed torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

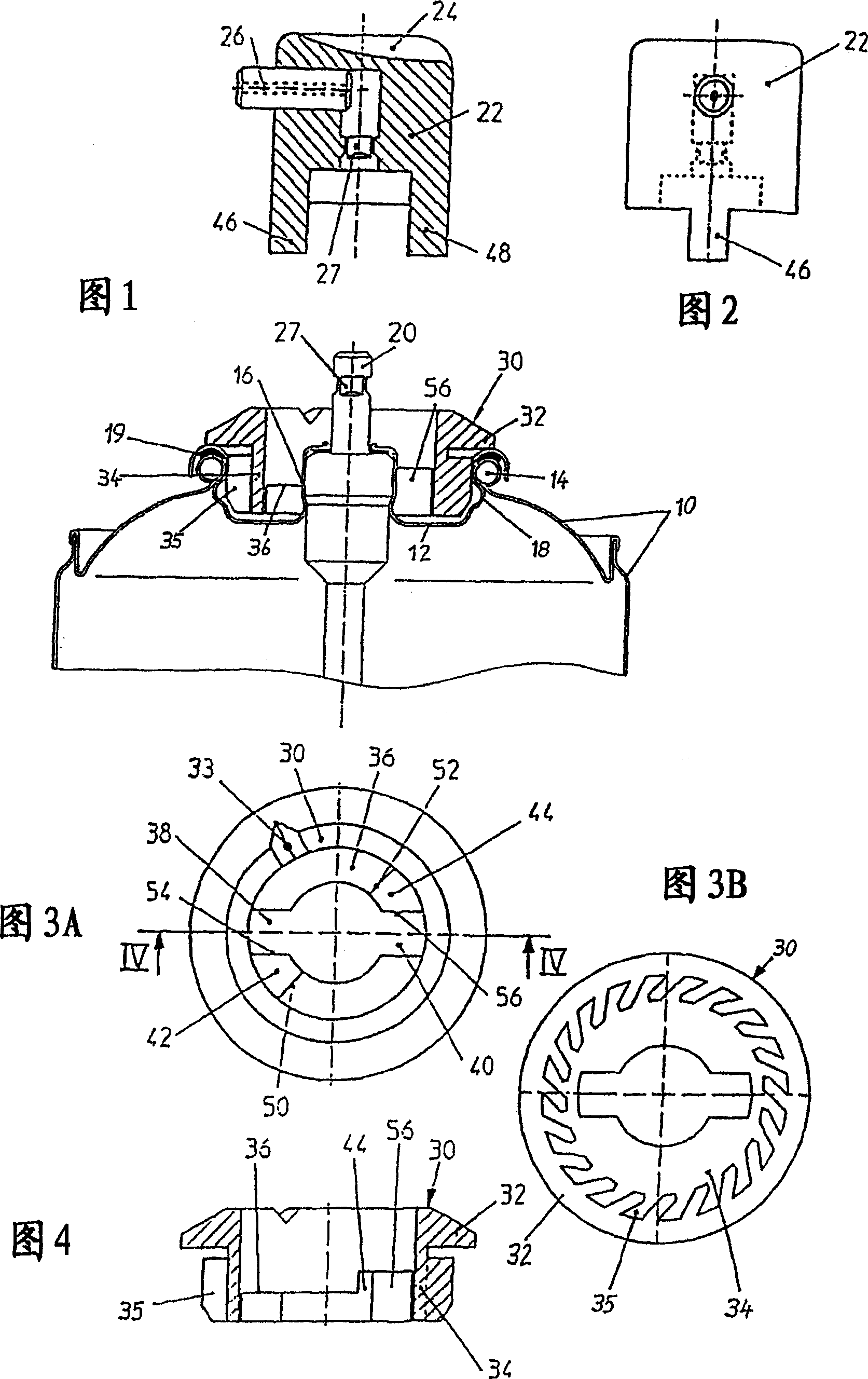

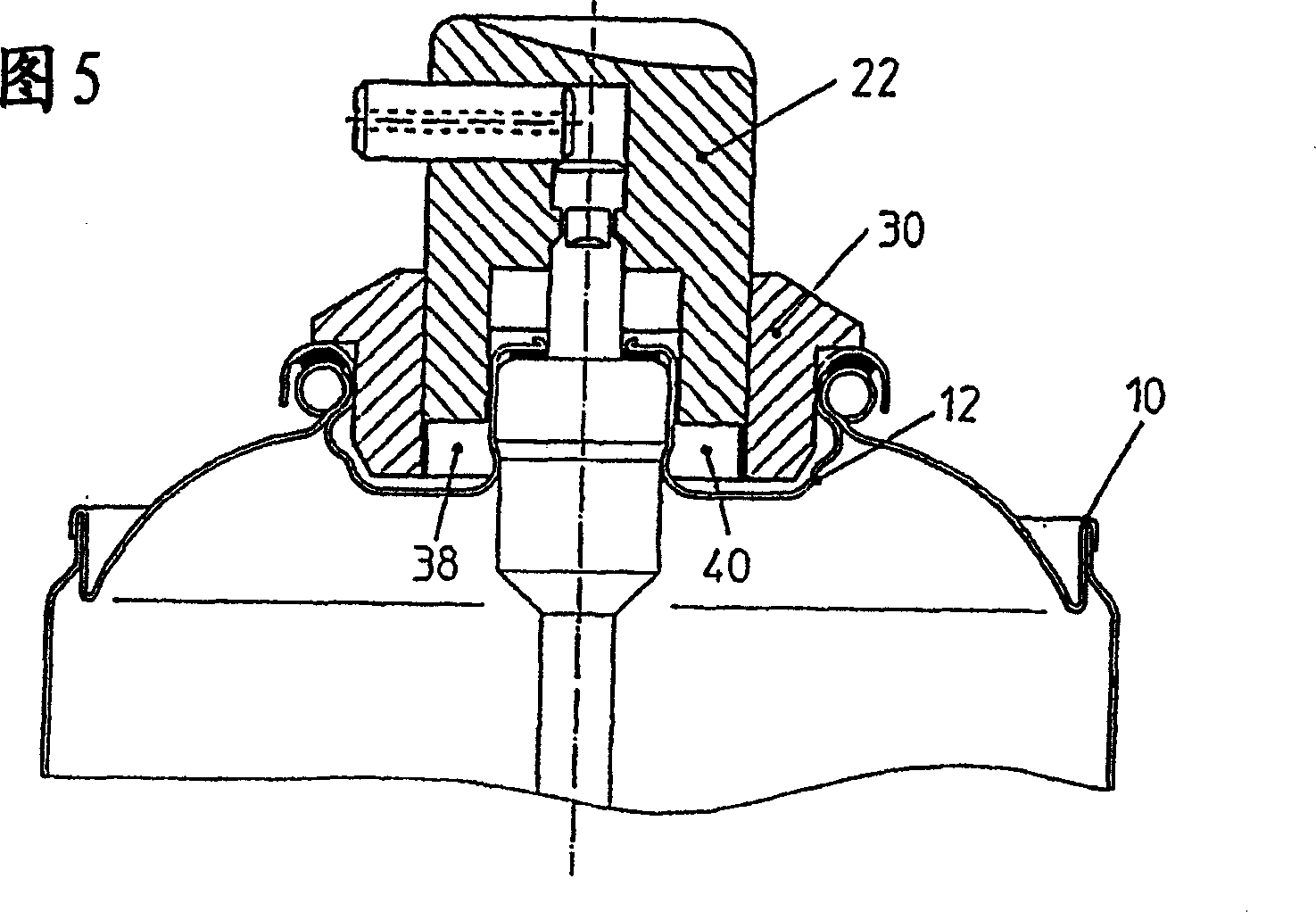

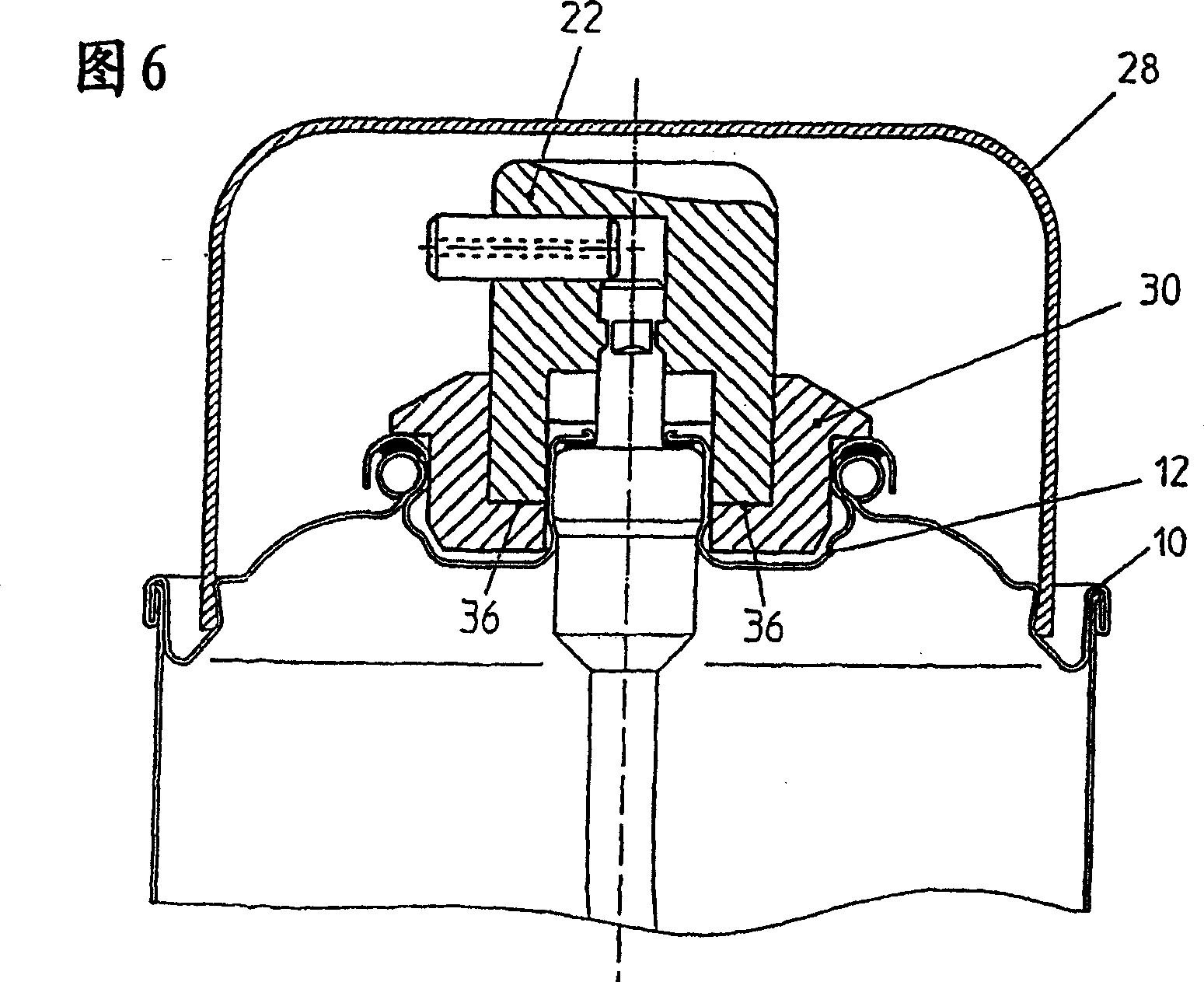

[0025] Shown in Fig. 1 is the top of an aerosol can, and its tank body is represented with 10, and its valve disc is represented with 12. For the invention it is immaterial whether the tank body 10 is made of tin in multiple pieces or in a single piece of aluminum alloy. The container opening provided with the beaded edge 14 in both cases is sealed by the corresponding valve disk 12 fastened thereon, which is formed in a common manner with a valve cover 16 in the region of its center and radially outside it. The region of the hood is formed with a flange 18 extending concentrically around the shroud. The valve housing 16 contains part of the spray valve, while the flange 18 is secured by clamping to the beaded edge 14 of the tank 10, with a sealing ring 19 or laminated sealing material achieving a tight seal.

[0026] Projecting upwards from the valve housing 16 is a push rod 20 which on the one hand serves as an actuating plunger for the spray valve in the housing 16 and on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com