Two-stage button switch

A switch and button technology, applied in the field of two-stage button switches, can solve the problems of difficult operation, short pressing stroke, and deterioration of operability, and achieve the effect of easy operation, reduced number of parts, and good operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

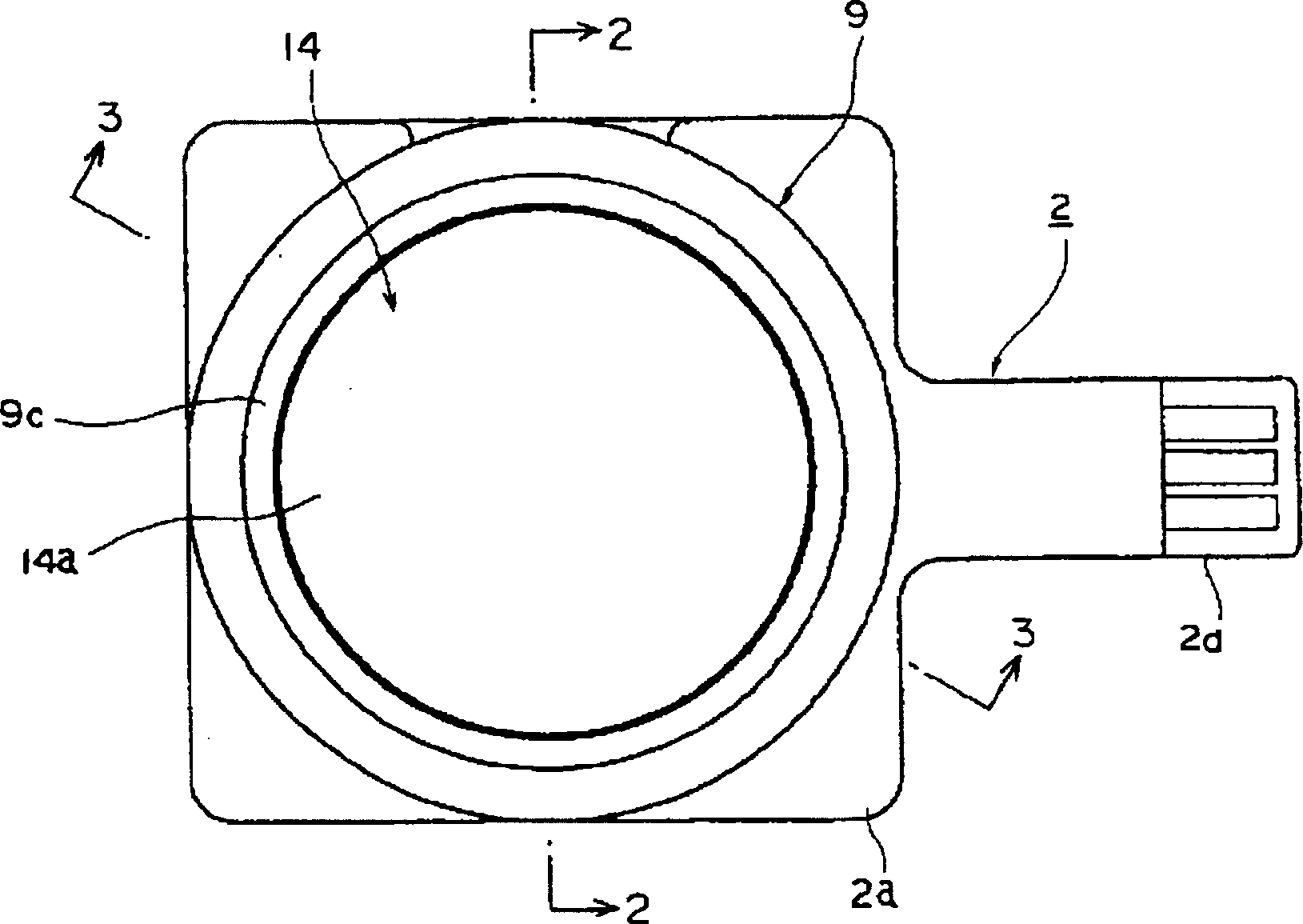

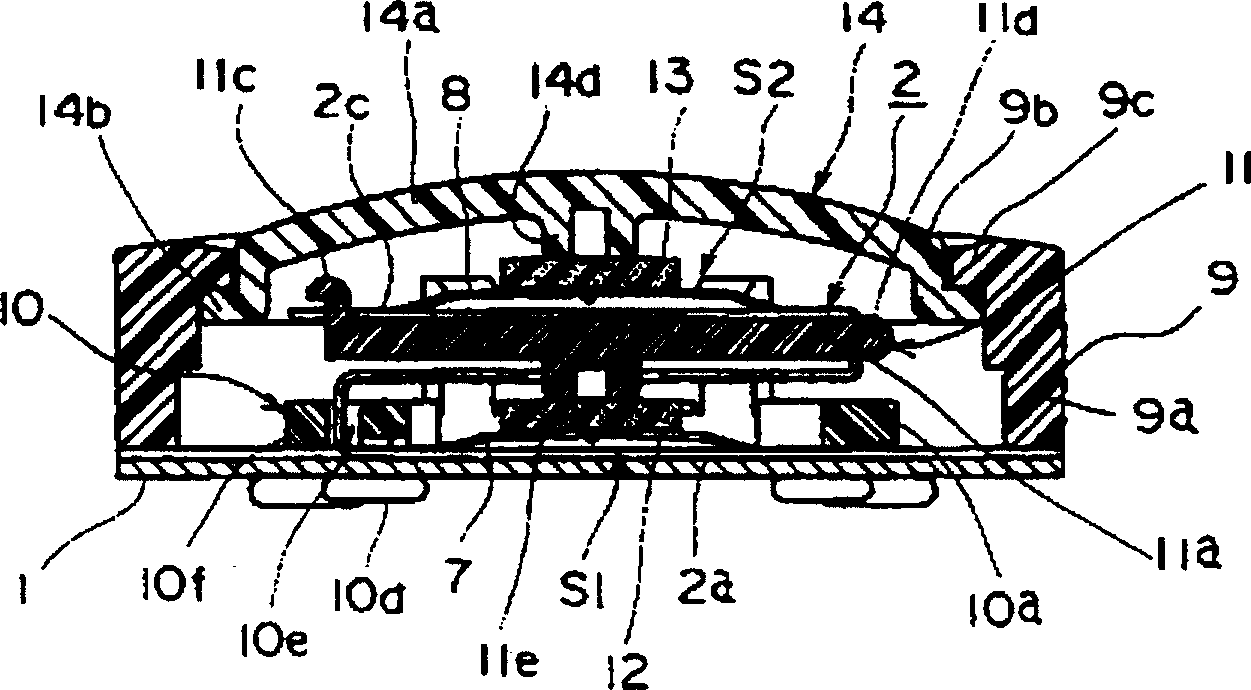

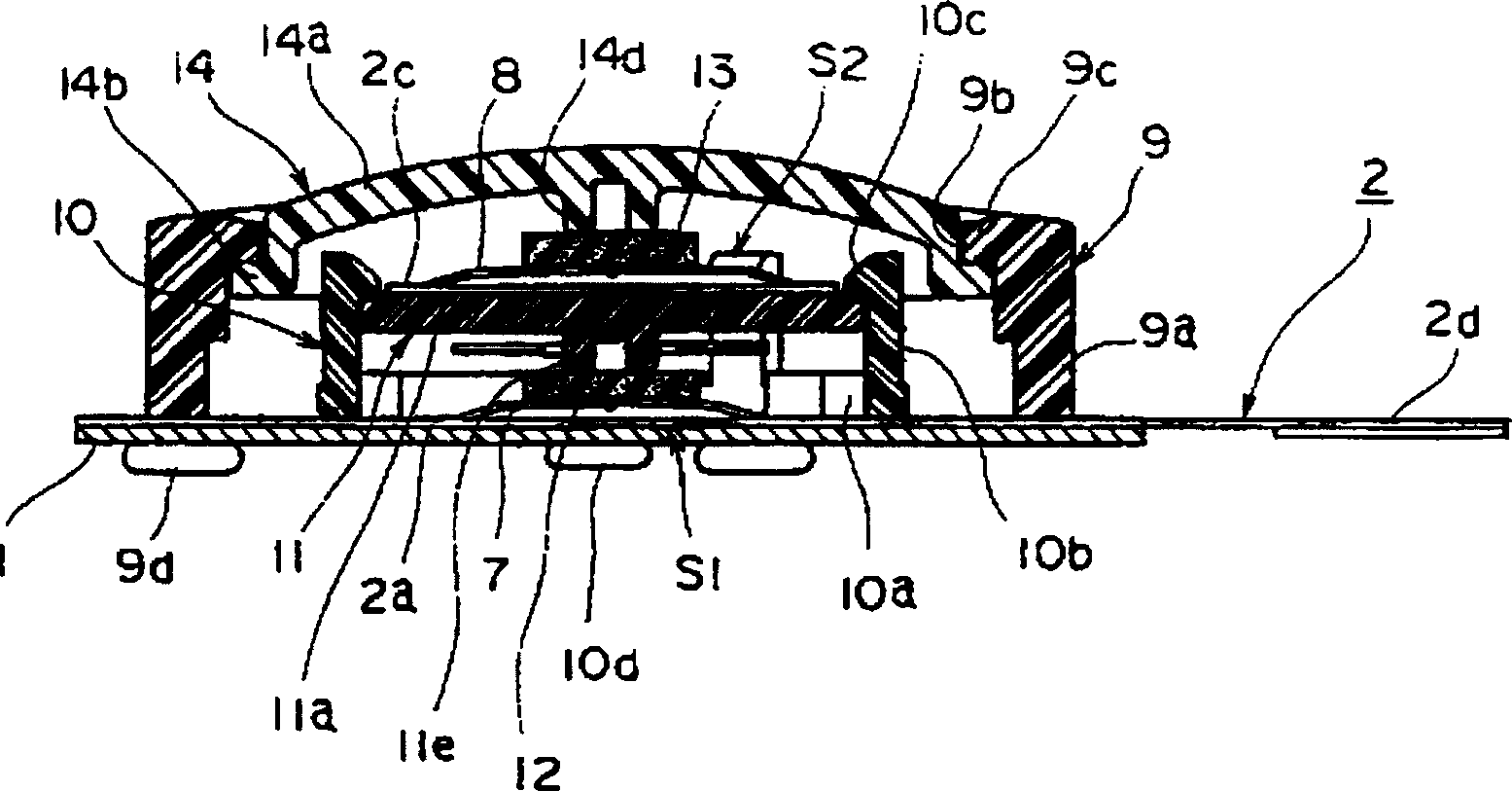

[0093] Below, according to Figure 1-Figure 21 To illustrate the structure of the two-stage push button switch of the present invention. The supporting portion 1 made of metal or the like has four mounting holes 1a provided on the outer side and three mounting holes 1b provided on the inner side. The flexible insulating substrate 2 made of polyester film is especially Figure 5 It has a rectangular base 2a as shown. A strip 2c extends from one side of the base 2a with cutouts 2b on both sides, and a strip 2d extending from one side of the base 2a at a position perpendicular to the strip 2c .

[0094] In addition, the flexible insulating substrate 2 has four mounting holes 2e provided on the outer periphery of the base portion 2a, two mounting holes 2f provided inwardly of the mounting holes 2e, and a circular hole 2g provided on the center of the belt-shaped portion 2c. , A pair of rectangular holes 2h, 2j are provided on the front end of the belt-shaped portion 2c at intervals fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com