Front lamp mounting structure of vehicle

A technology for headlights and vehicles, which is applied to lighting devices, vehicle parts, fixed lighting devices, etc., can solve the problems of water and dust pollution, large gaps, and poor appearance quality, so as to improve precision, improve rigidity, maintain The effect of weight balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

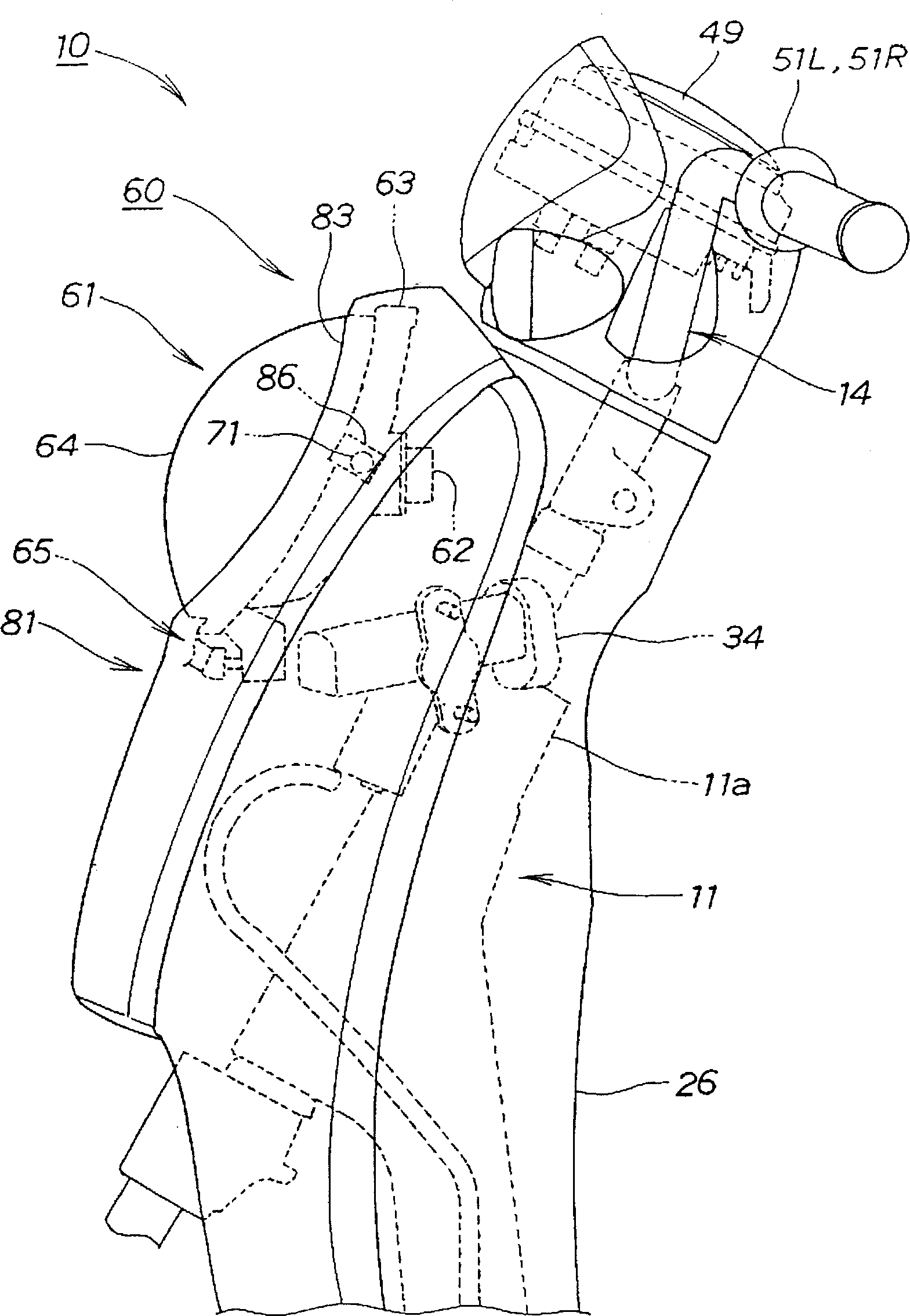

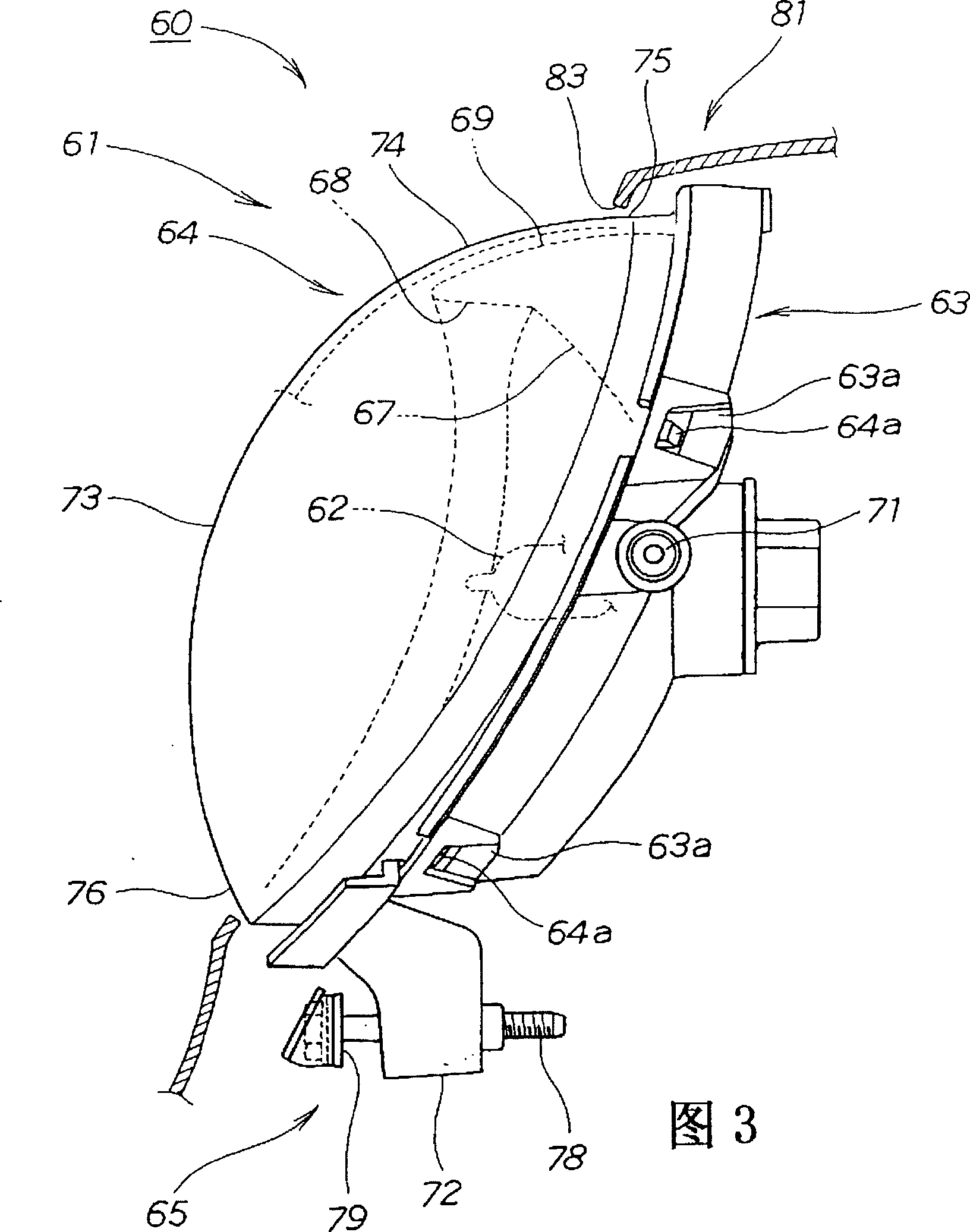

[0027] Embodiments of the present invention will be described below with reference to the accompanying drawings. "Front", "Rear", "Left", "Right", "Up", and "Down" refer to the direction seen by the driver, Fr refers to the front side, Rr refers to the rear side, L refers to the left side, and R refers to the right side . In addition, the figure surface is a figure seen from the direction of a symbol.

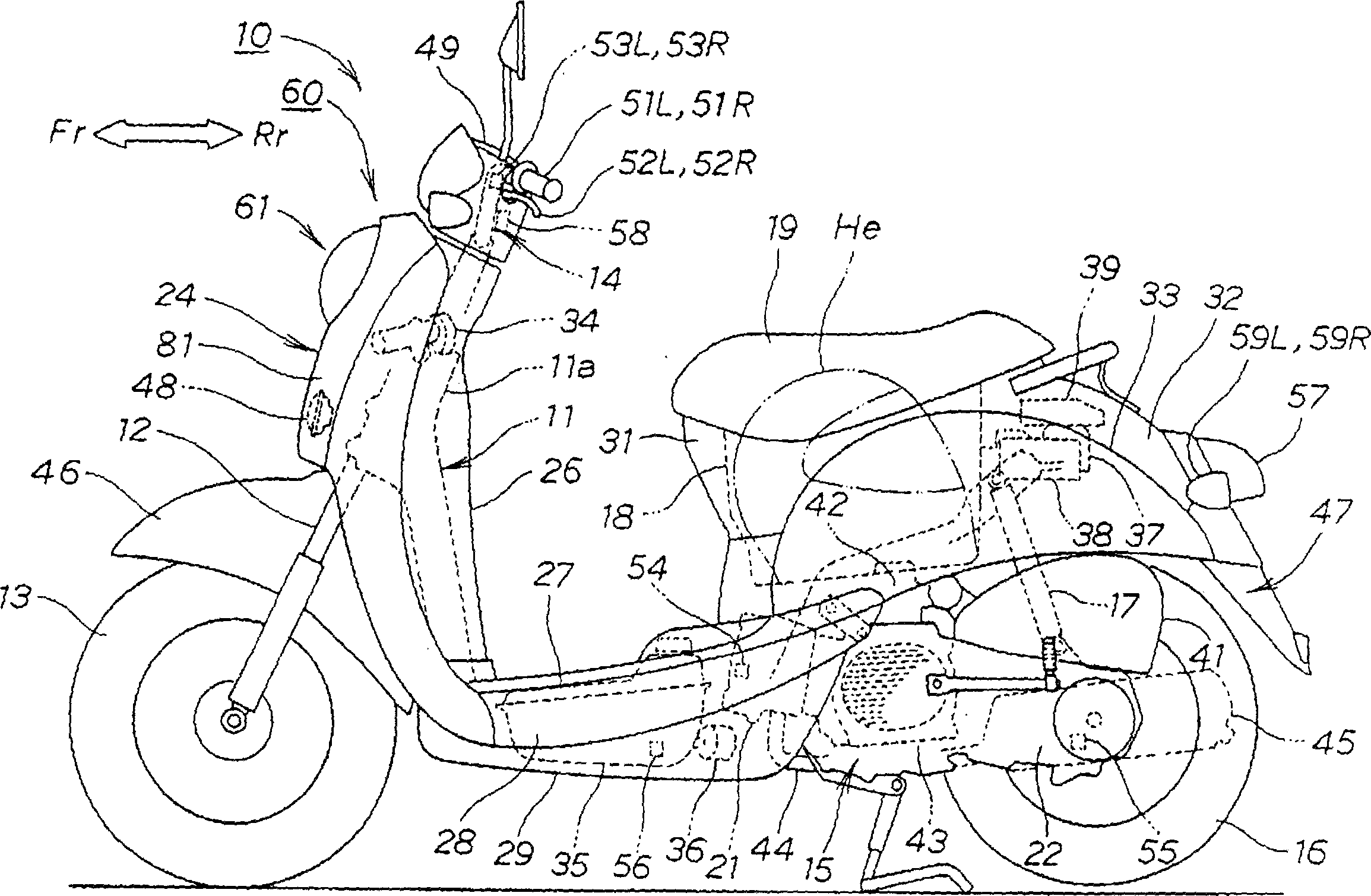

[0028] figure 1 It is a side view of a motorcycle employing the vehicle headlight mounting structure of the present invention.

[0029] The two-wheeled motor vehicle 10 is a small motorcycle type two-wheeled motor vehicle, and is mainly connected to The handle 14 on the front fork 12, the power unit 15 installed on the rear portion of the vehicle frame 11 swingably up and down, the rear wheel 16 installed on the power unit 15, the rear buffer unit 17 at the rear end of the suspension power unit 15 , a storage box 18 mounted on the rear upper portion of the vehicle frame 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com