Pushbutton structure

A button and keycap technology, applied in the field of button structure, can solve problems such as wrong signal input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

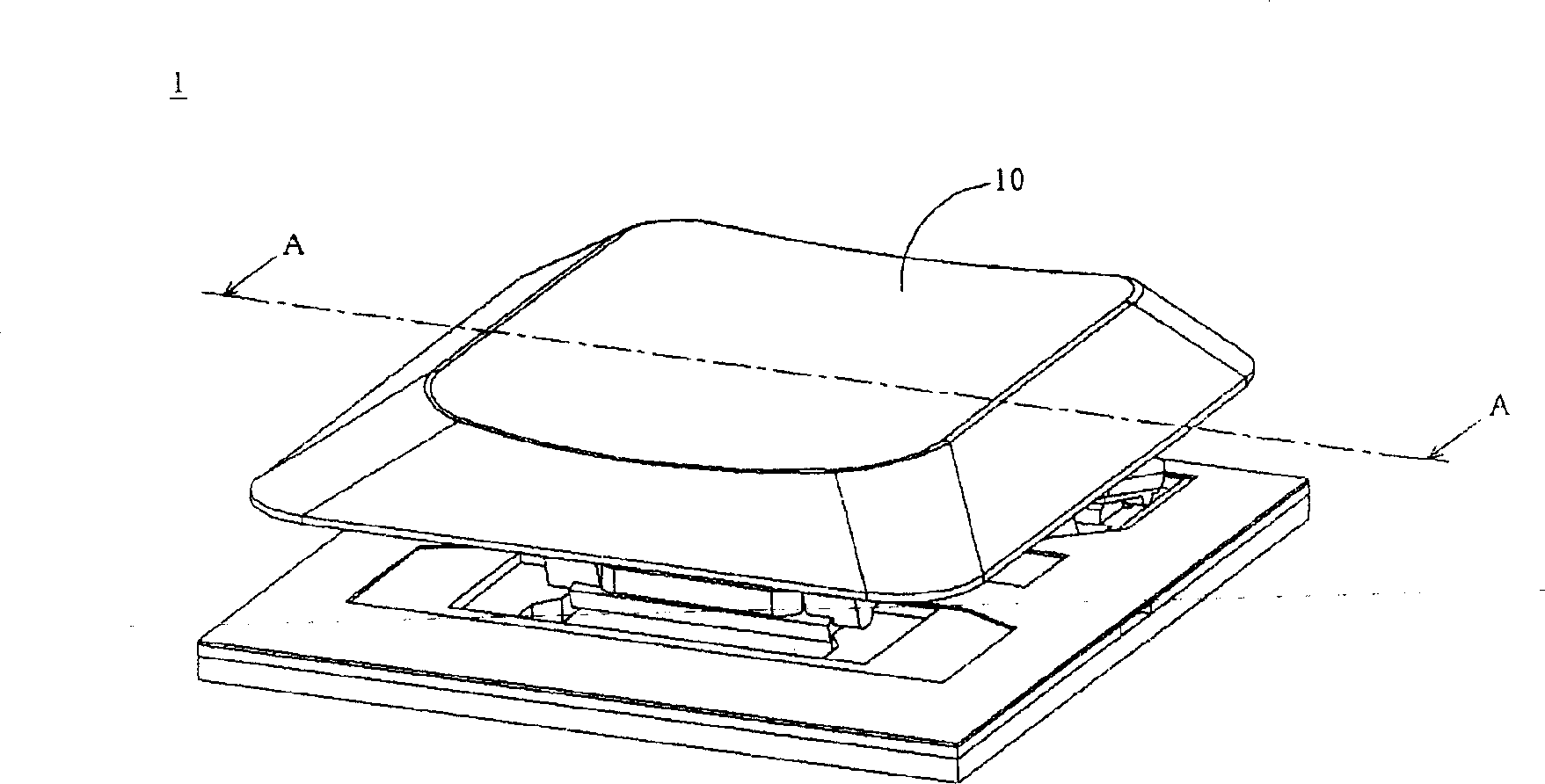

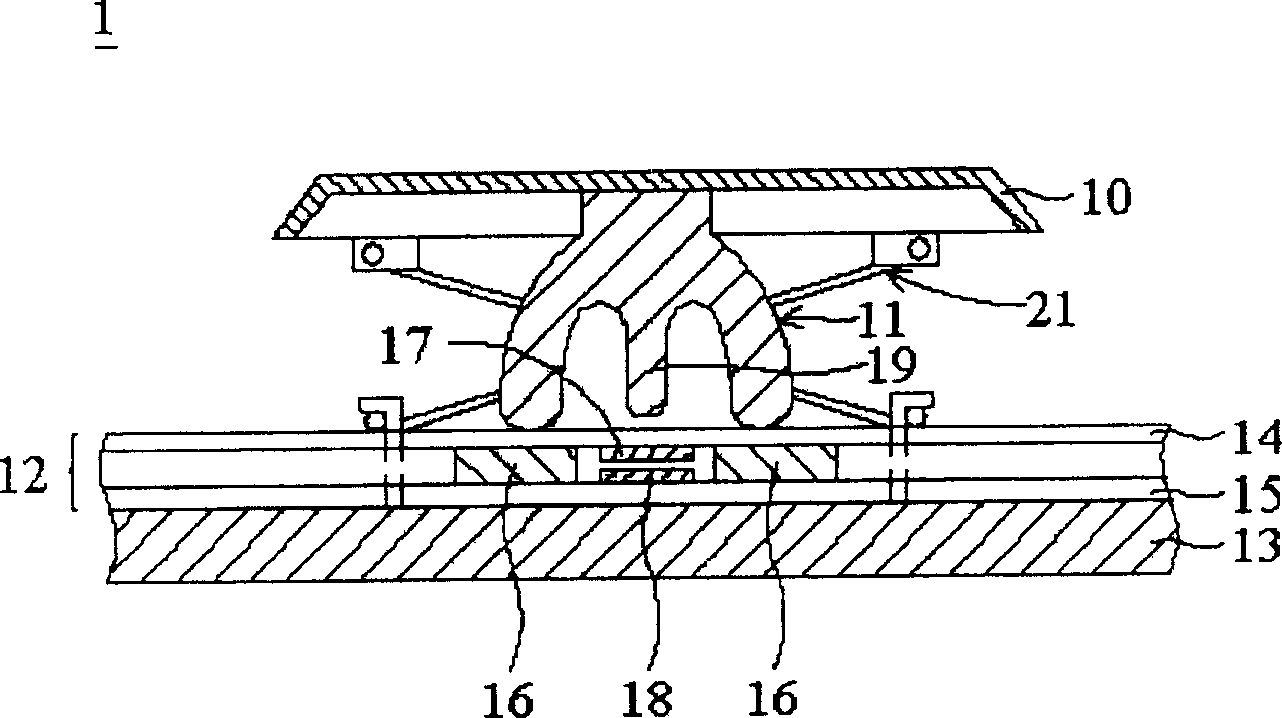

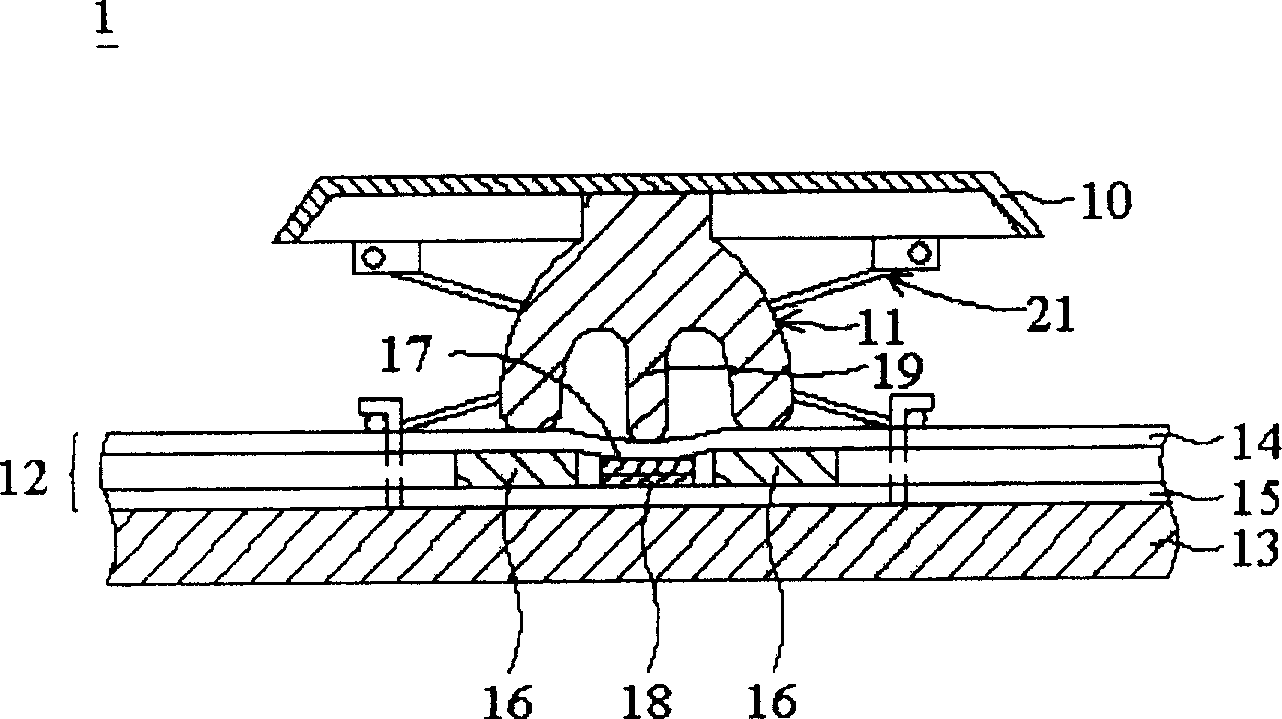

[0028] see Figure 5 , the button structure 100 of the present invention mainly includes a keycap 110 , an elastic body 120 , a film component 130 , a substrate 140 and a connecting mechanism 145 . The elastic body 120 is connected to the keycap 110 and disposed under the keycap 110 . The film component 130 is disposed under the elastic body 120 . The substrate 140 is disposed under the thin film assembly 130 . One end of the connecting mechanism 145 is connected to the substrate 140 , and the other end of the connecting mechanism 145 is connected to the keycap 110 . The keycap 110 is connected to the base plate 140 in a manner that can move up and down through the connecting mechanism 145 .

[0029] The film assembly 130 has a first film 150 , a second film 160 and a spacing element 170 . A first conduction portion 180 and a second conduction portion 190 are respectively provided on the opposite surfaces of the first film 150 and the second film 160, and the first conduct...

no. 2 example

[0033] see Figure 6 The difference between this embodiment and the first embodiment is only that the foreign object removal portion 210 of the substrate 140 is a concave portion, and the structure and arrangement of the other key structure 100 components are the same as those of the first embodiment, so no further description is given.

[0034] Likewise, when foreign matter such as dust or sand exists on the substrate 140 , the foreign matter may fall into the concave portion 210 . Therefore, when the thin film assembly 130 is disposed on the substrate 140, the second thin film 160 will not protrude due to foreign matter on the substrate 140, and furthermore, the first thin film 160 will not be damaged when the key structure 100 is not touched. Improper electrical connection occurs between the first conducting portion 180 of the thin film 150 and the second conducting portion 190 of the second thin film 160 .

no. 3 example

[0036] see Figure 7 , the button structure 300 of this embodiment is a button structure of a mobile phone. The difference between this embodiment and the first and second embodiments is that the structure of the keycap 110' of the key structure 300 is different from that of the keycap 110 of the key structure 100. At the same time, the key structure 300 does not have a connection mechanism, that is, the keycap 110' is not connected to the substrate 140 in a manner that can move up and down through the connection mechanism, so the up and down movement of the keycap 110' is directly conduct. In addition, the structure and configuration of the remaining components of the key structure 300 are the same as those in the first embodiment, so details are not repeated here.

[0037]Likewise, when foreign matter such as dust or sand exists on the substrate 140 , the foreign matter can be discharged through the through hole. Therefore, when the thin film component 130 is disposed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com