Beading mechanism of hydraulic double-action stretching machine

A stretching machine and edge-holding technology, which is applied in the field of edge-holding mechanism and hydraulic double-action stretching machine, can solve the problem that it is difficult to meet the pressure required for compaction, unfavorable stretching quality, and small compaction force and other problems, to achieve the effect of easy realization, reduced machine cost and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

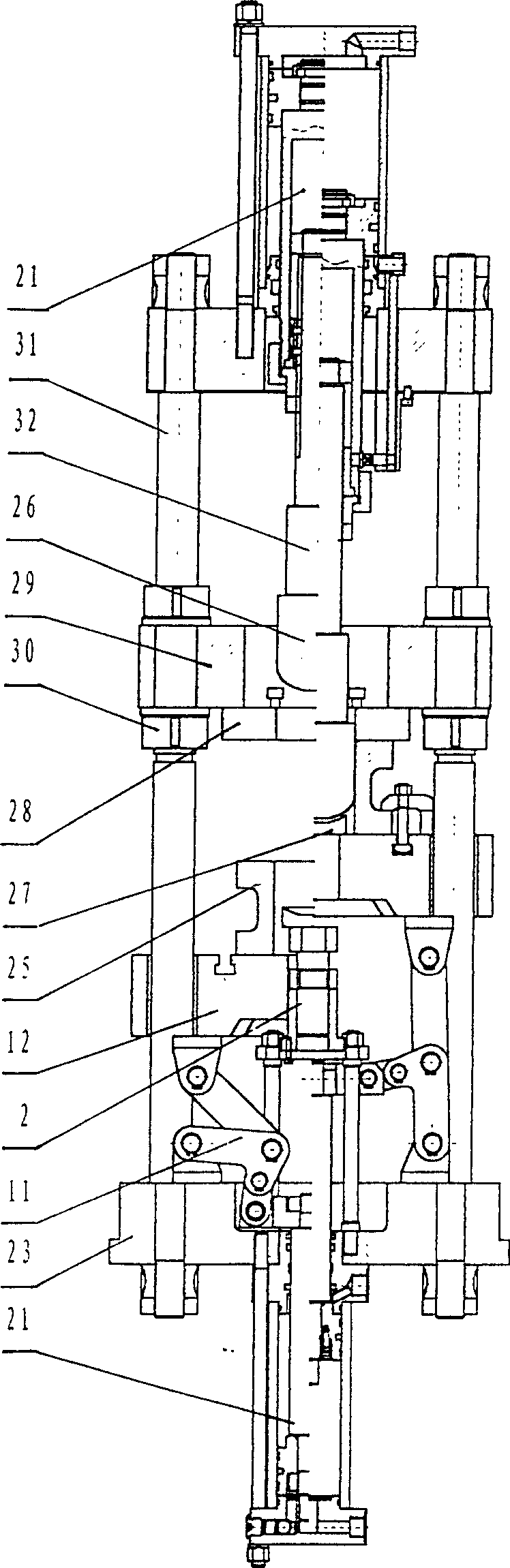

[0013] The complete machine of the hydraulic double-action stretching machine in this embodiment is as follows: figure 1 As shown, it mainly consists of an upper oil cylinder, a column 31, a central screw 32, a punch 26, a blanking platen 29, a lock nut 30, a blanking template 28, a stripper plate 27, a die 25, a working table 12, a top Extruder 2, edge clamping device 11, machine base 23, lower oil cylinder 21 are formed.

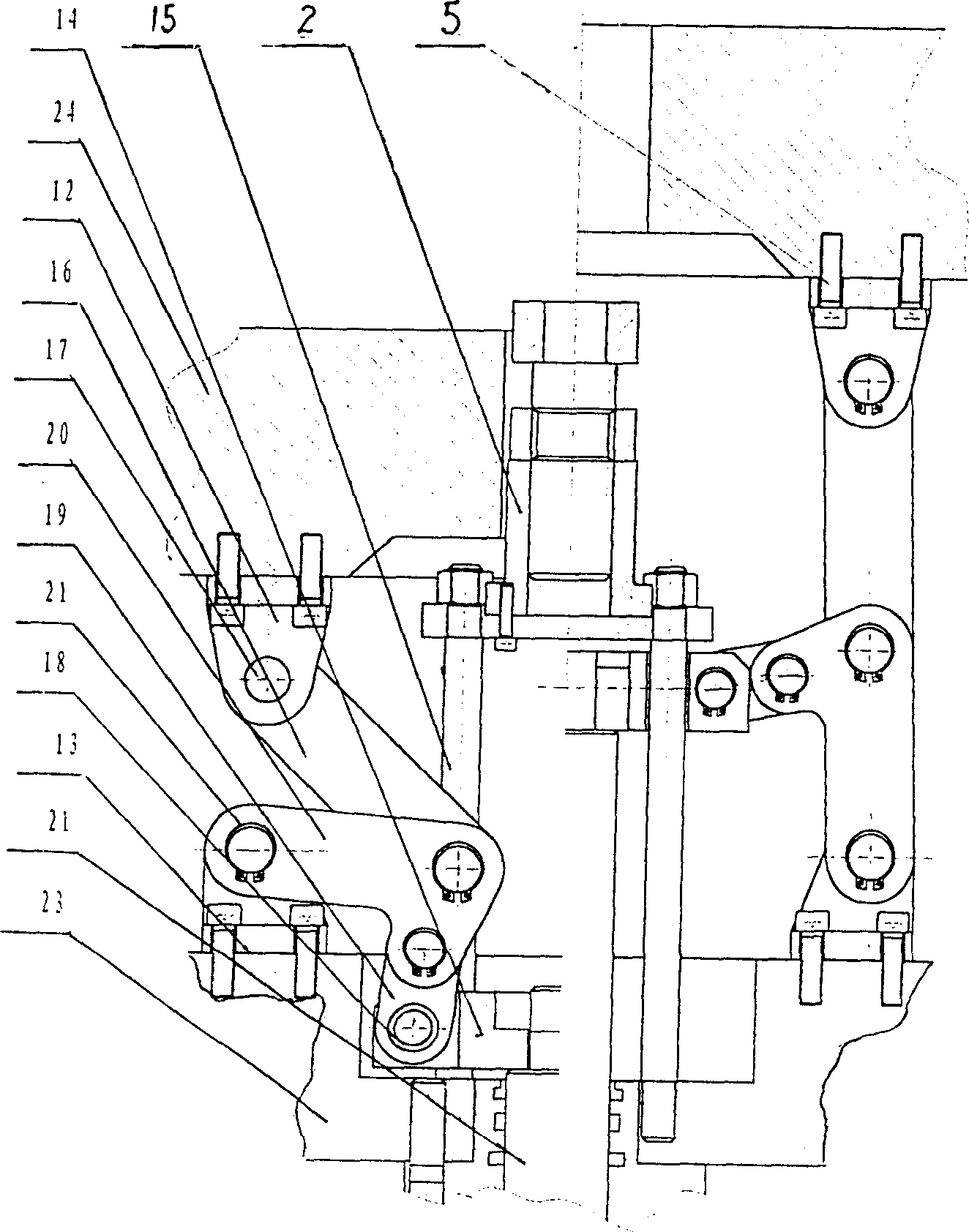

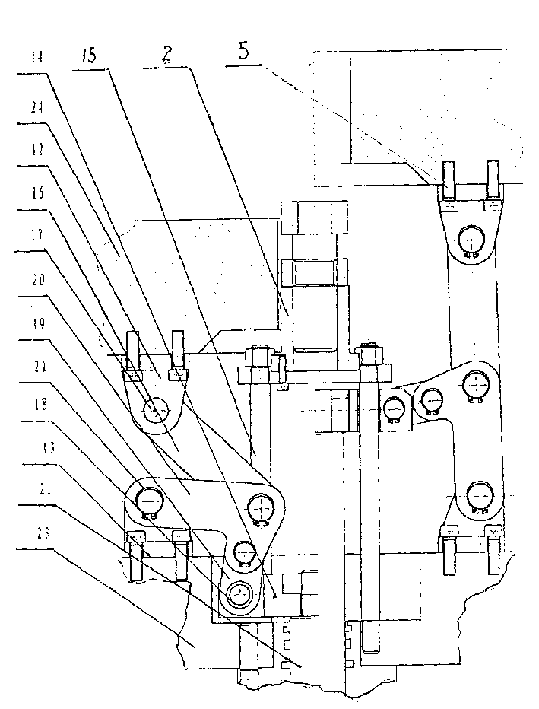

[0014] The specific situation of the edge pressing mechanism is as follows: figure 2 As shown, it includes a worktable 12 that can move along the column 31 fixed on the base 23, a lower oil cylinder 21 installed on the base 23, a sliding bracket 14, a short connecting rod 19, a curved connecting rod 20 and a long connecting rod 16 . The sliding bracket 14 is fixedly connected with the piston rod end of the lower oil cylinder 21 . There are four short connecting rods 19, curved connecting rods 20 and long connecting rods 16, wherein one end of the four ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com