Centrifugal pump having adjustable clean-out assembly

A technology for centrifugal pumps and adjusting components, which is applied to parts, pumps, pump elements, etc. of pumping devices for elastic fluids, and can solve the problems of frequent removal of cleaning components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

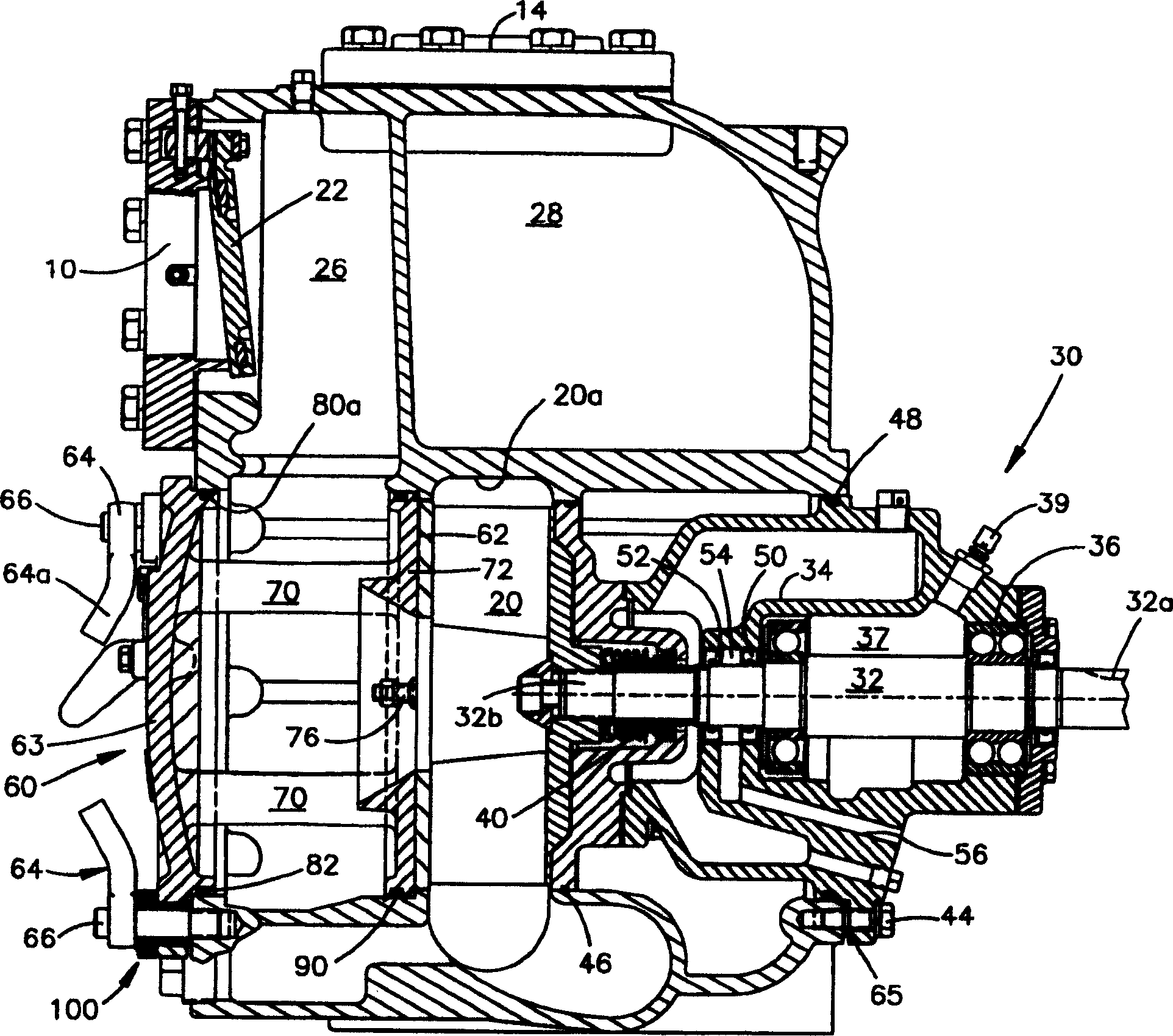

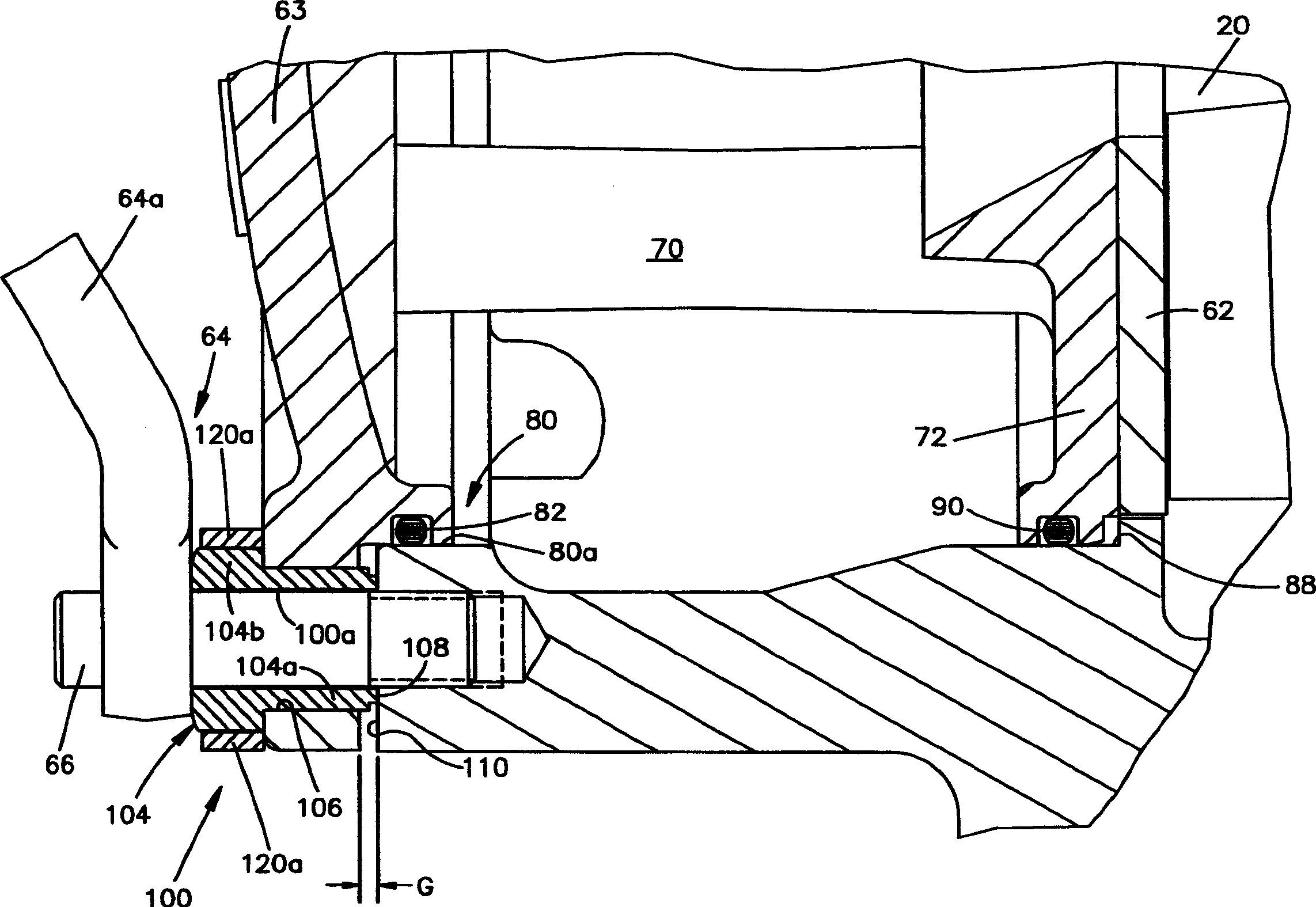

[0024] figure 1 with 2 The general structure of a centrifugal pump incorporating the present invention is described. For ease of illustration, the present invention will be described in conjunction with a self-priming pump. The pump described is of the type disclosed in US Patent No. 3,898,014 owned by the assignee. A detailed description of the operation of a self-priming pump can be obtained by reference to US Patent No. 3,898,014, which is hereby incorporated by reference and appended hereto as Appendix 1.

[0025] The present invention can also be adapted to other types of centrifugal pumps, such as those disclosed in copending U.S. Provisional Application No. 60 / 178,174, filed January 26, 2000, which is hereby also incorporated by reference and incorporated herein as Annex 2 is attached hereafter.

[0026] refer to figure 1 with 2 Both, the disclosed self-priming pump includes an inlet or suction port 10 through which the fluid to be pumped is drawn and an outlet or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com