Floor covering plate

A technology of ground covering and floor plates, applied in the direction of floors, dovetail connections, circuits, etc., can solve problems such as low bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

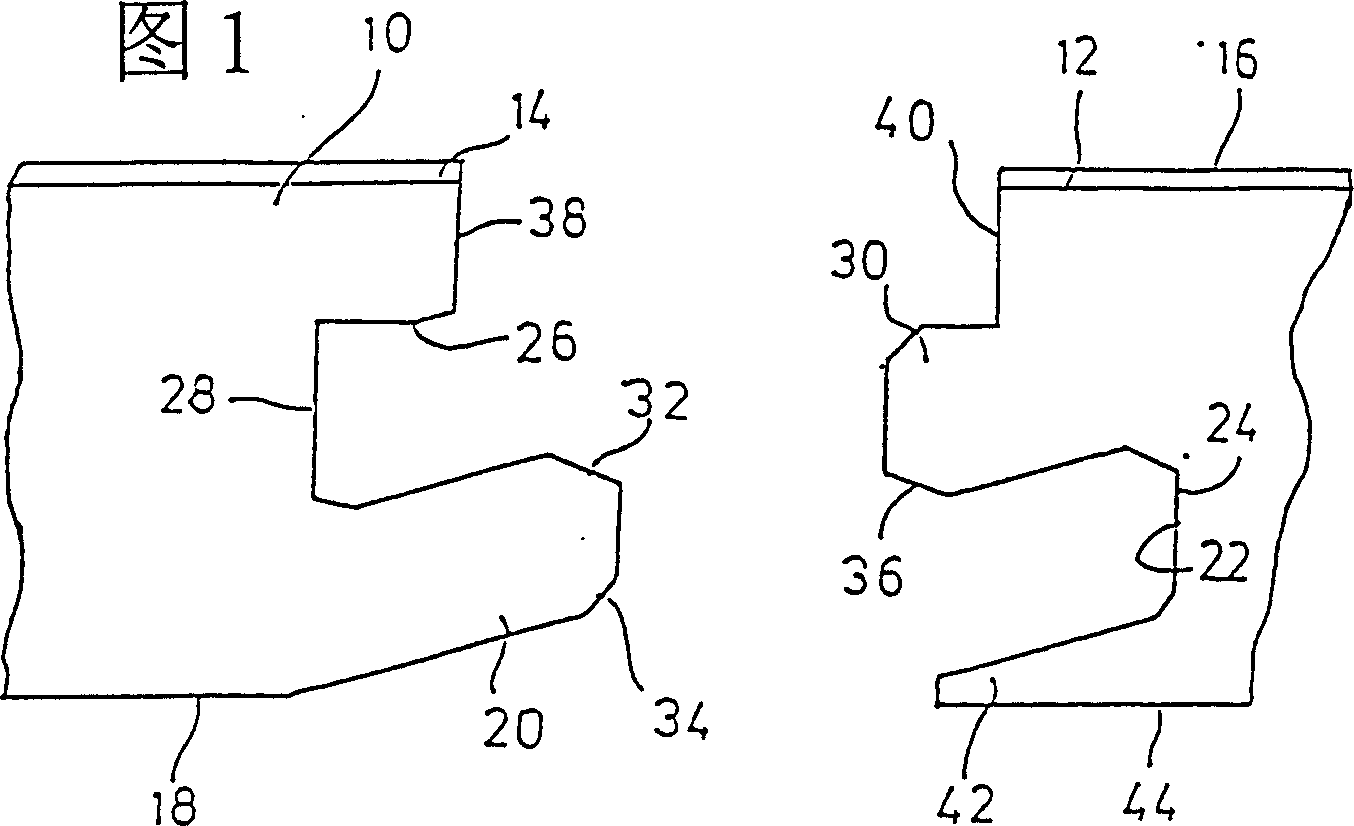

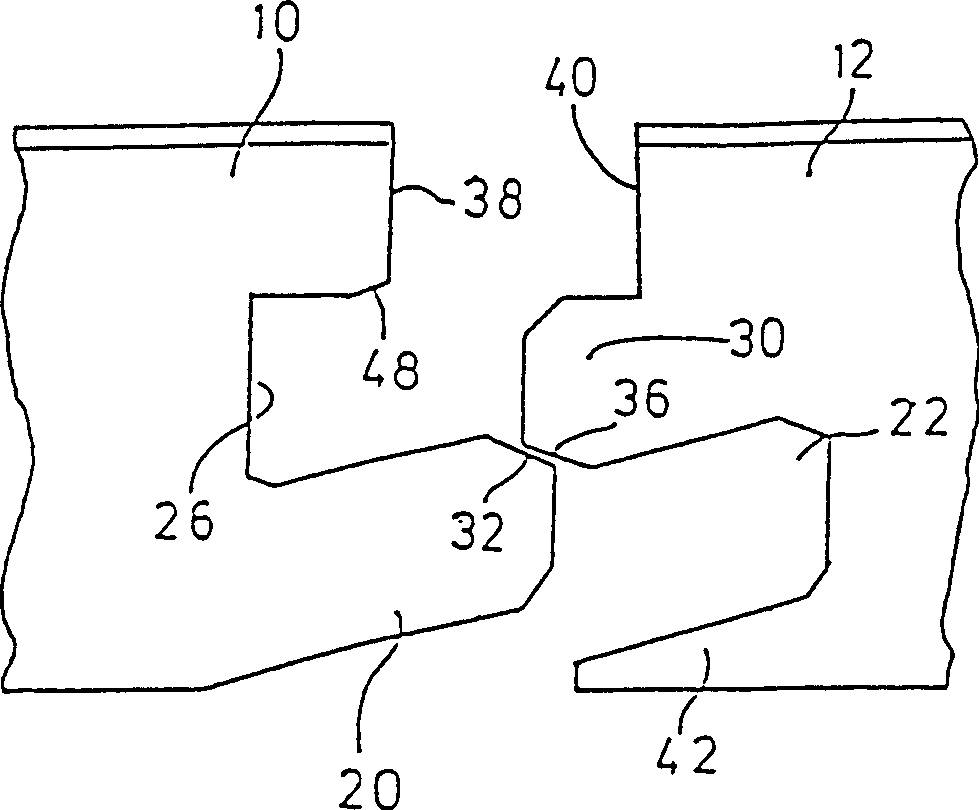

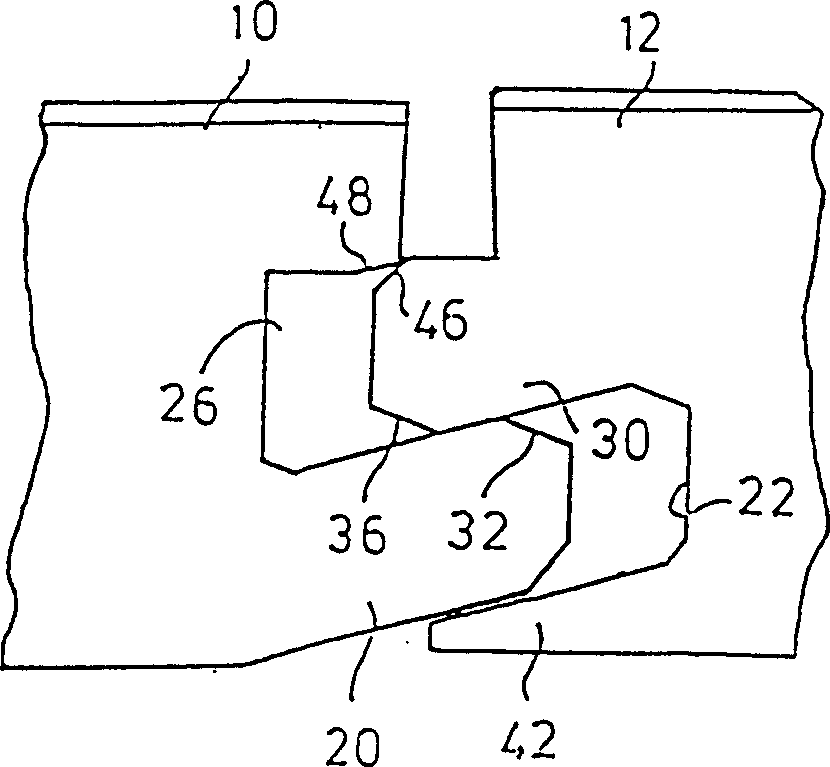

[0033] FIG. 1 shows the edges of two floorboards to be joined, of which the left-hand one will be referred to below as the first floorboard 10 and the right-hand one as the second floorboard 12 . The floorboards 10 and 12 may be made of laminate, ie of derived wood products and / or plastic, or of compacted wood. The top cover layers 14, 16 are represented here by way of example. The first floorboard 10, shown on the left in FIG. The inside of the groove 22, ie towards the rear end 24 of the groove, is at the same angle as the tongue 20 protrudes upwards.

[0034]Arranged above the obliquely raised tongue 20 in the first floorboard is a groove 26 , the bottom wall of which is formed by the top surface of the tongue 20 sloping down towards the groove rear end 28 . Instead, the top wall of the groove 26 extends substantially horizontally, which is parallel to the floor plane of the two floorboards 10 , 12 .

[0035] The top of the groove 22 in the second floorboard 12 is define...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com