Fixing piece for a windscreen wiper

A technology for fixing parts and wipers, which is used in vehicle cleaning, vehicle maintenance, transportation and packaging, etc., can solve problems such as contact corrosion in the connection area, and achieve the effect of eliminating contact corrosion and reducing manufacturing time and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

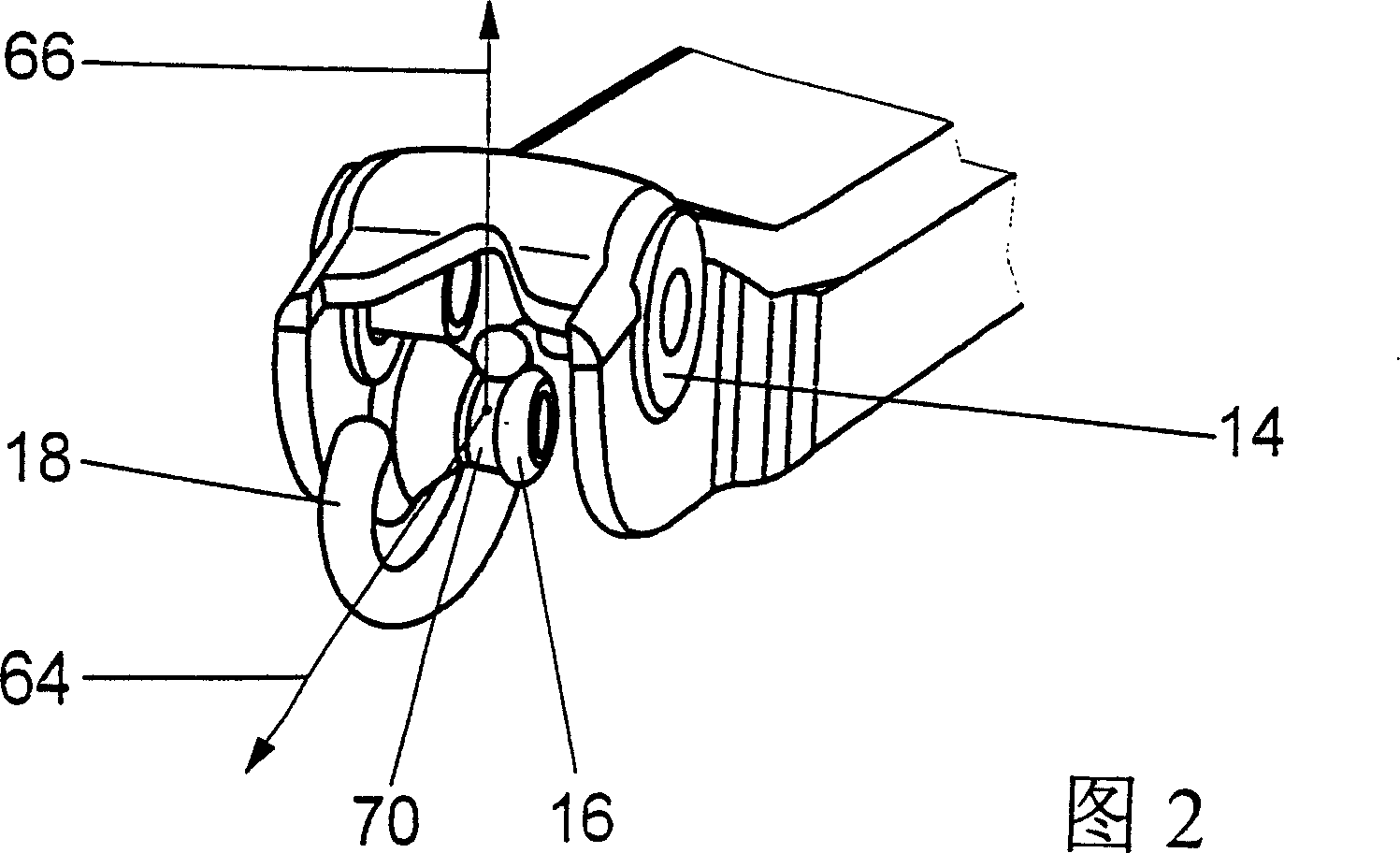

[0022] The fastening part 10 for the windshield wiper has at its one end a receiving opening 12 or 46 ( FIG. 10 ) for receiving the wiper shaft 44 and at its other end forms a component 14 of the folding hinge ( FIG. 1 ). Furthermore, the fastening part 10 has at this end a shaped spring suspension 16 on which a C-shaped hook 18 of a tension spring (not shown) engages. The spring suspension 16 is formed by deep drawing from the side walls 24 of the U-shaped cross-sectional profile 20 ( FIGS. 2 and 9 ).

[0023] Via the C-shaped hook 18, considerable tensile forces 64 and 66 act on the spring suspension 16 from different directions. The cross-section of the spring suspension 16 has a circular hollow profile, which has a maximum cross-section in the transition region to the side wall 24 until it is reduced to a constriction 34, whereby the cross-section of the spring suspension 16 The section is correspondingly solidly constructed. The constriction 34 forms the engagement regi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com