Multifunctinal scraper stirring ball mill

A multi-functional technology of agitating ball milling, applied in grain processing and other directions, it can solve the problems of limiting the research scope of new materials, easy sticking of powder on the cylinder wall, difficulty in reclaiming, etc., to solve oxidation and pollution, improve sealing reliability, expand The effect of the development range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

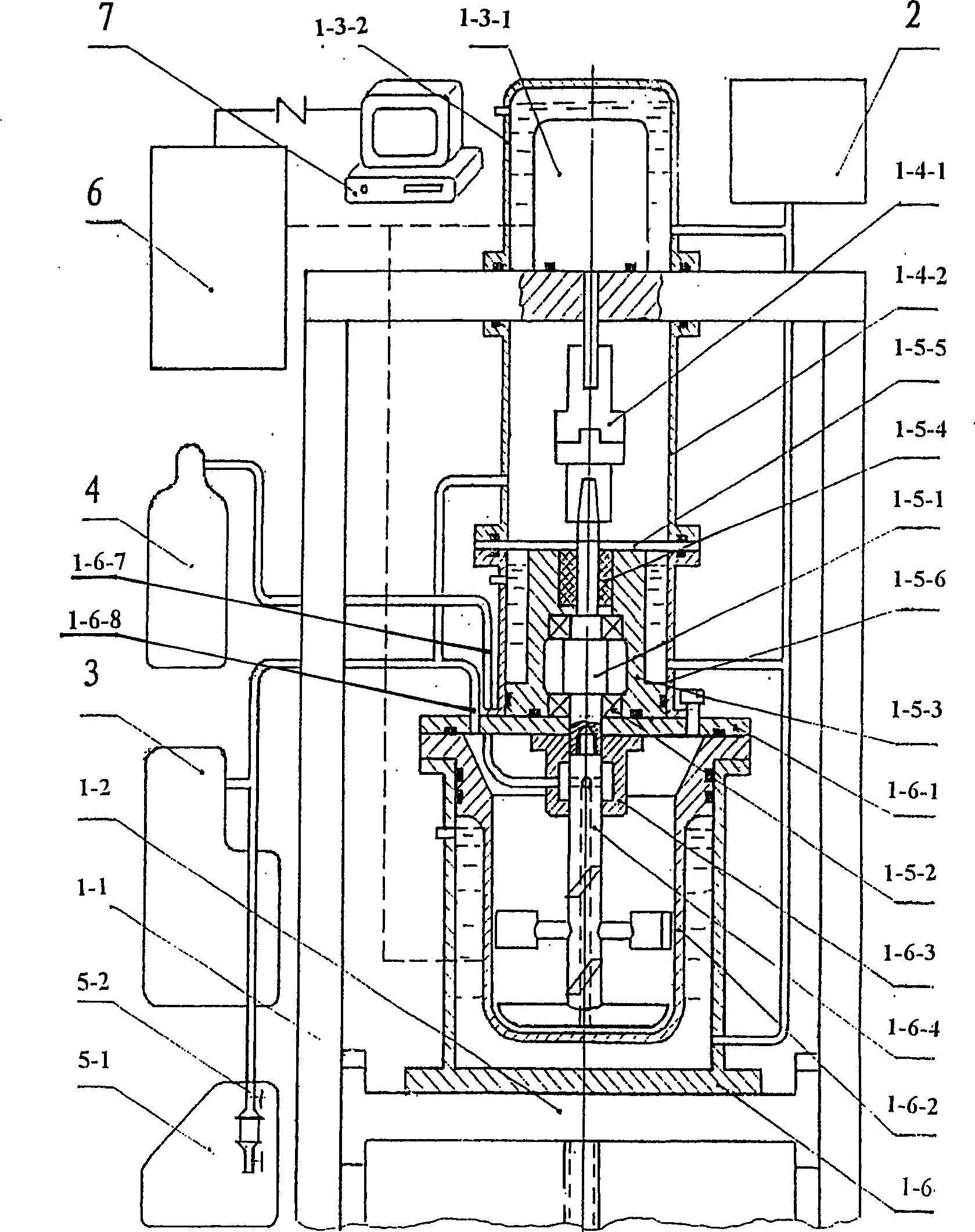

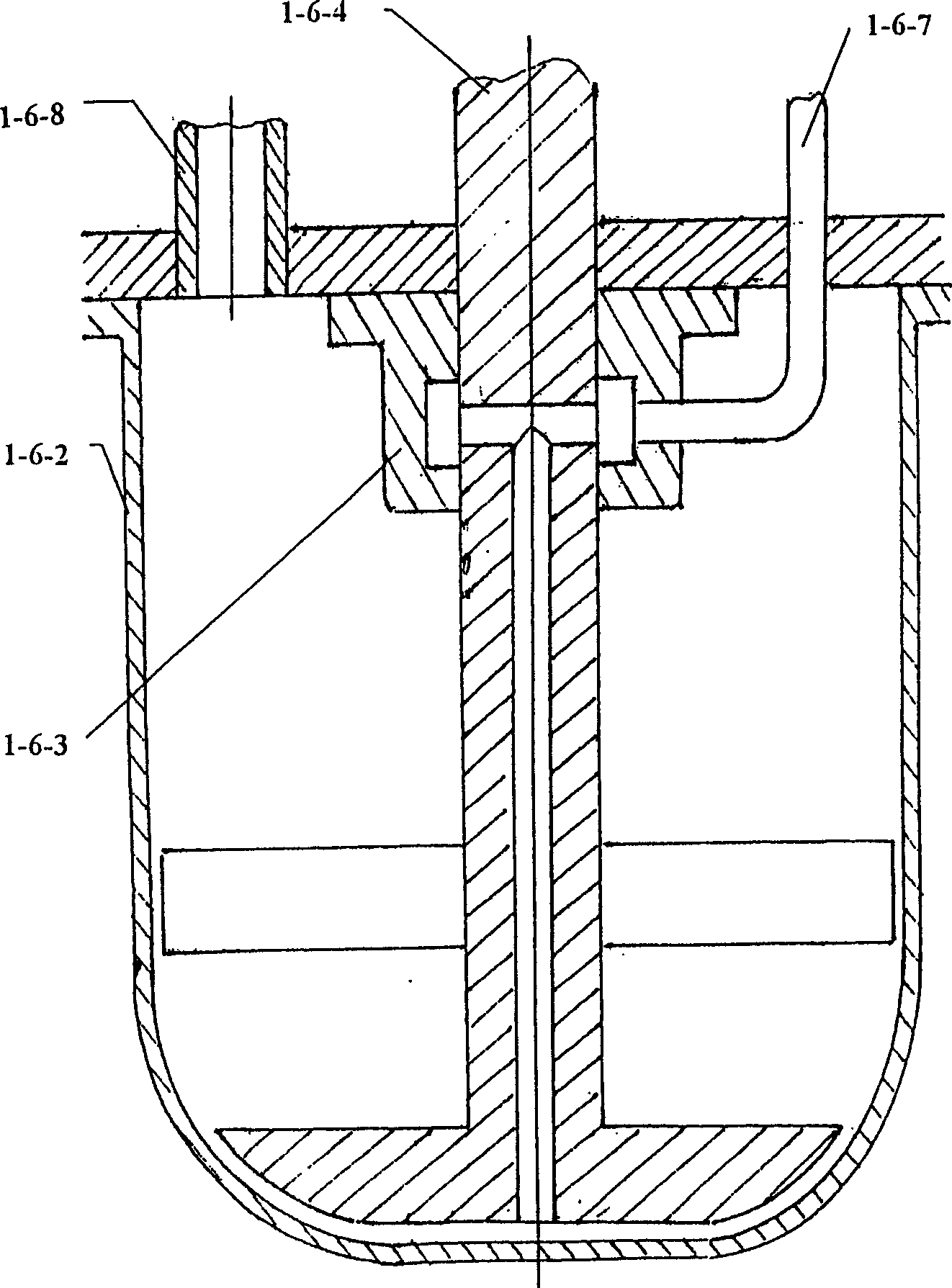

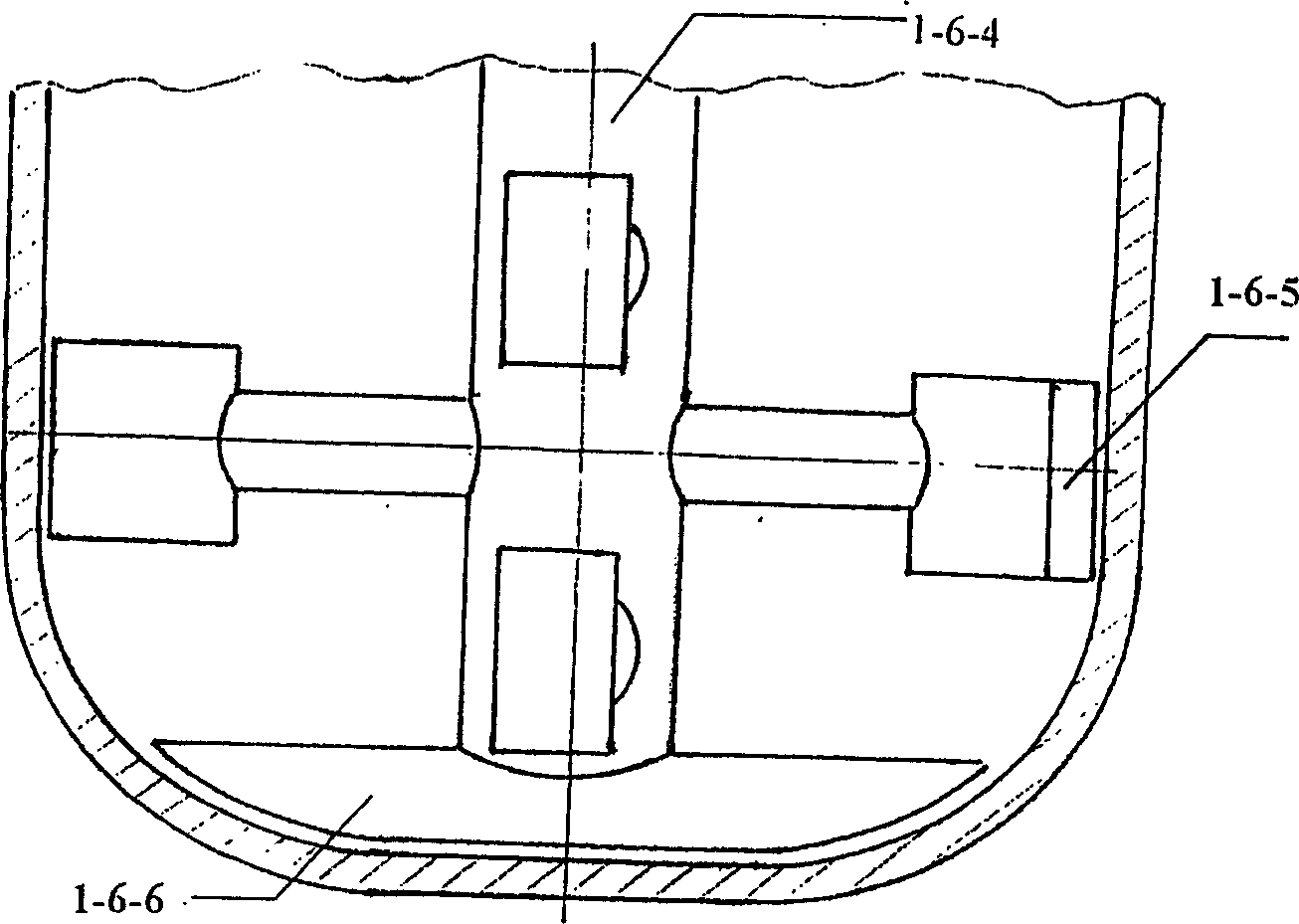

[0025] Accompanying drawing is the specific embodiment of the present invention

[0026] Below in conjunction with accompanying drawing, content of the present invention will be further described

[0027] refer to figure 1 As shown, the multifunctional spatula-stirred ball mill is composed of a host and additional peripheral equipment, and its host is composed of a body 1-1, a lifting platform 1-2, a motor 1-3-1, and a coupling 1-4- 1. Main shaft 1-5-1 and ball mill tank 1-6, and additional peripheral equipment is composed of cooling system 2, vacuum system 3, air supply system 4, material reclaiming system 5, measurement and control system 6, and computer remote control system 7. Said that the upper beam of the gantry frame of the fuselage 1-1 of the main engine is connected with a motor 1-3-1, and the lower end is connected with a lifting platform 1-2; the output shaft of the motor 1-3-1 is connected with a shaft coupling 1-4-1, A first housing 1-4-2 is provided on the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com