Cleaning or application device comprising sponge body, and method for producing same

A technology of coating device and sponge body, which is applied to household cleaning devices, cleaning machinery, cleaning equipment, etc., can solve problems such as labor-intensive and achieve the effect of less material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

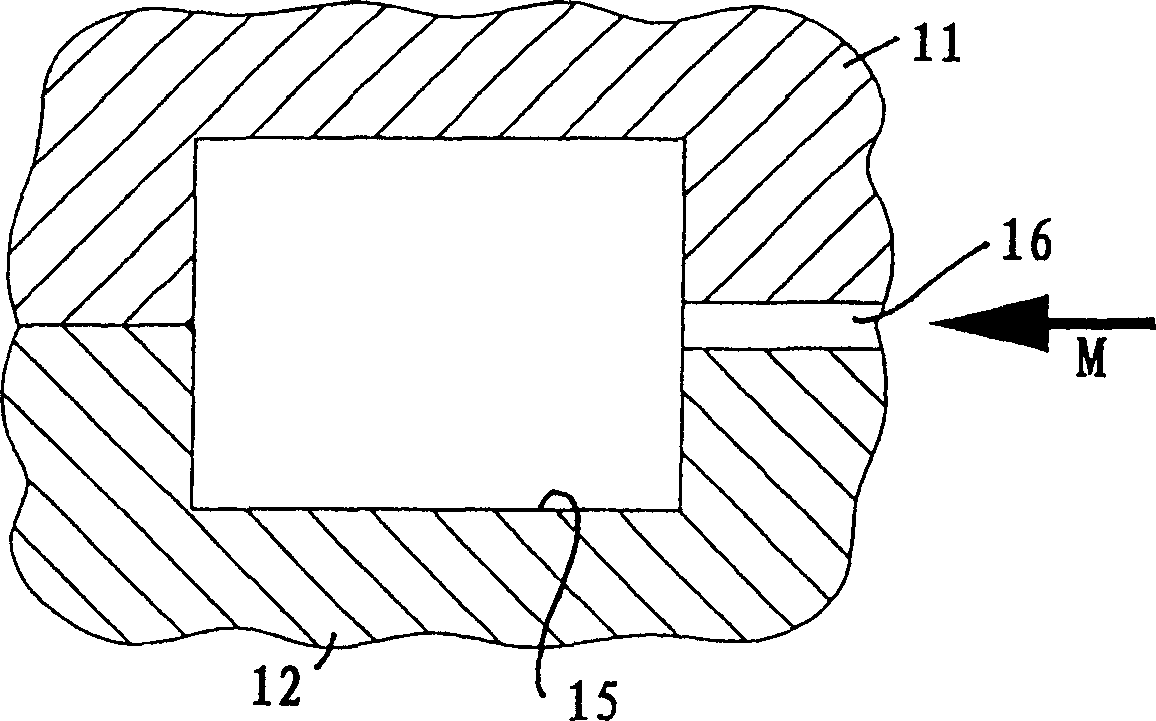

[0063] figure 1 A mold for producing a sponge according to the method of the invention is shown schematically. The mold comprises two mold halves 11 and 12 defining a cavity 15 between them. Foamed plastic material, in particular soft polyurethane foam, can be introduced via a delivery channel 16 into the mold cavity 15 and foamed therein, as indicated by the arrow M. FIG. The size and shape of the mold cavity 15 correspond substantially to the final shape or configuration of the sponge. After opening the mold, a reinforced shell 13 with an internal uniform closed-cell structure and continuous closure is obtained, which is relatively stable and can be formed on the outside of the sponge body 10 by selectively adjusting the method parameters in the foaming process, as shown in the figure shown in 2. The shell 13 can be partly excised in order to obtain the spongy body 10 shown in FIG. The remaining solid housing 13 can be used as a stable handle part for the user or for mou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Foam density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap