Process for preparing etching cream of glass fibre

A technology of glass filament and frosting, which is applied in the field of preparation of glass silk screen frosting paste, which can solve the problems of affecting the frosting effect, complicated operation, and low efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

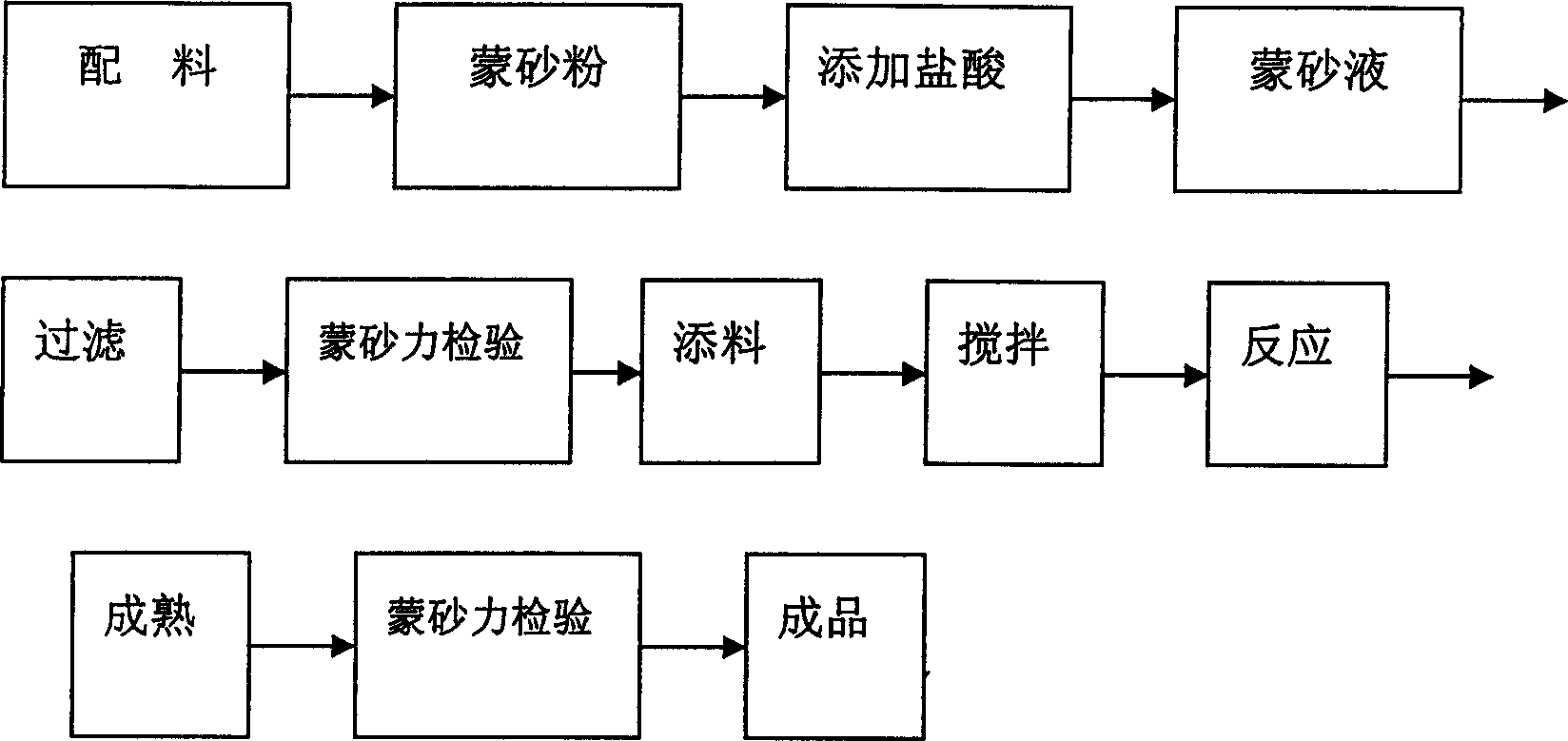

Image

Examples

Embodiment 1

[0005] Embodiment 1: With reference to accompanying drawing, at first prepare frosting powder, in 100 grams, 55 grams of ammonium bifluoride, 5 grams of ammonium fluoride, 4 grams of calcium fluoride, 6 grams of sodium fluoroborate, 5 grams of potassium fluoroborate, fluoroboric acid 3 grams of magnesium, 4 grams of oxalic acid, 6 grams of starch, 8 grams of barium sulfate, and 4 grams of sodium fluorosilicate; put the above mixture in a rotary stirring tank and stir it for 20 minutes; mix the frosting powder and industrial hydrochloric acid by 1 : 0.5 to carry out the mixed reaction to obtain the frosting liquid, the time of the mixed reaction is 30 hours, the frosting liquid is filtered with 10-100 order ordinary screen or nylon mesh to obtain a uniform milky frosting liquid; a clean glass sheet is placed in the Filtrate for 30 seconds, it can be seen that the glass sheet has been frosted evenly, and the frosting cream is prepared, and its weight ratio is as follows (in 100 g...

Embodiment 2

[0006] Embodiment 2: With reference to accompanying drawing, at first prepare frosting powder, in 100 grams, 35 grams of ammonium bifluoride, 8 grams of ammonium fluoride, 9 grams of calcium fluoride, 10 grams of sodium fluoroborate, 10 grams of potassium fluoroborate, fluoroboric acid 4 grams of magnesium, 4 grams of oxalic acid, 7 grams of starch, 10 grams of barium sulfate, and 3 grams of sodium fluorosilicate; put the above mixture in a rotary stirring tank and stir for 25 minutes; mix the frosting powder and industrial hydrochloric acid by 1 : 1 to carry out mixed reaction to obtain frosting liquid, the time of mixed reaction is 50 hours, the frosting liquid is filtered with 10-100 order ordinary screen or nylon net to obtain uniform milky frosting liquid; a clean glass sheet is placed in the Filtrate for 50 seconds, you can see that the glass sheet is frosted evenly, prepare the frosting paste, its weight ratio is as follows (in 100 grams): 35 grams of milky frosting liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com