Valve rod cap of air conditioner service valve

A technology for checking and repairing valves and air conditioners. It is applied in the direction of lifting valves, valve devices, and valve details. It can solve problems such as high cost, impossible to distinguish whether the stop parts are removed, and difficult to determine the stop structural parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

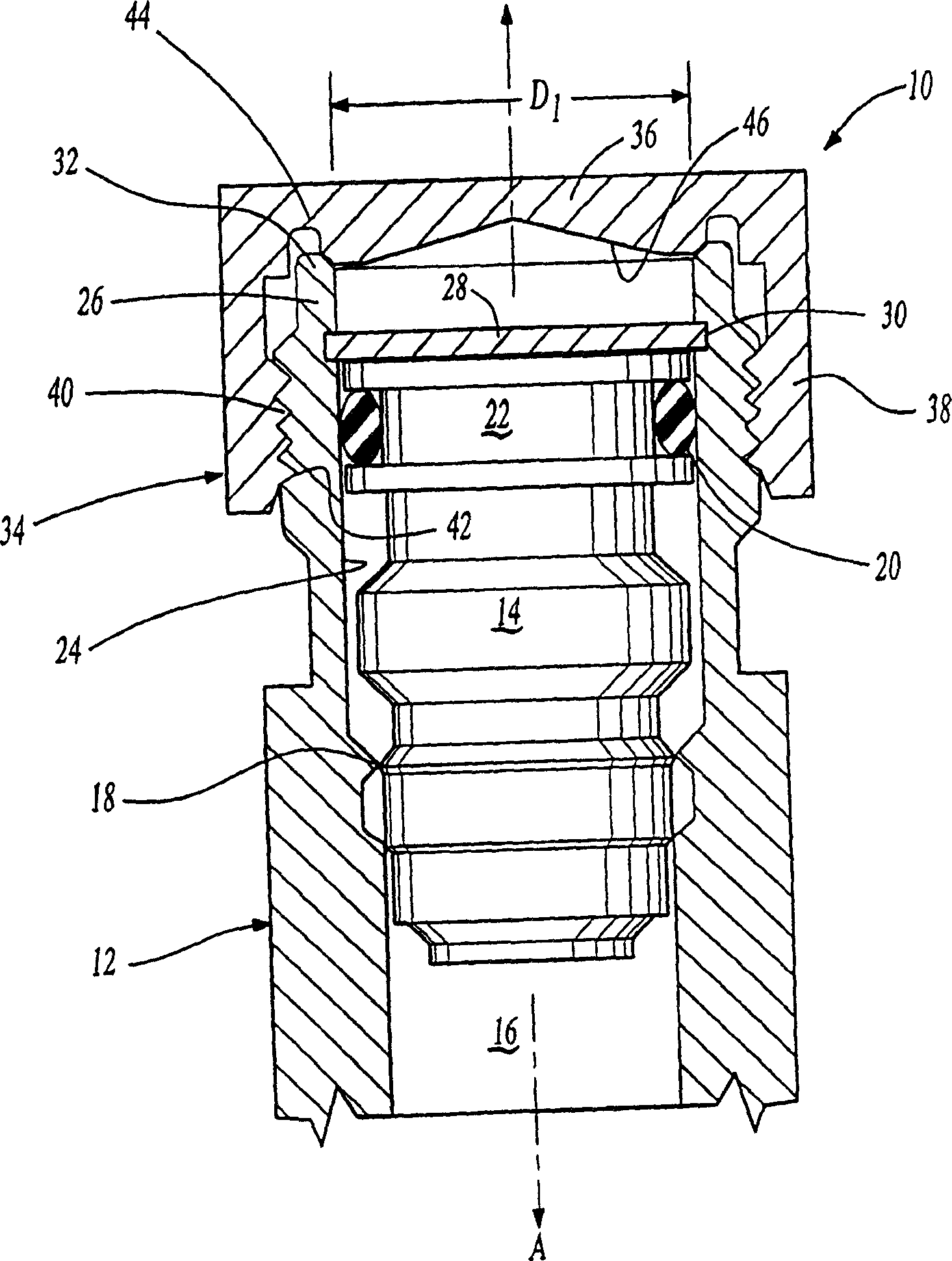

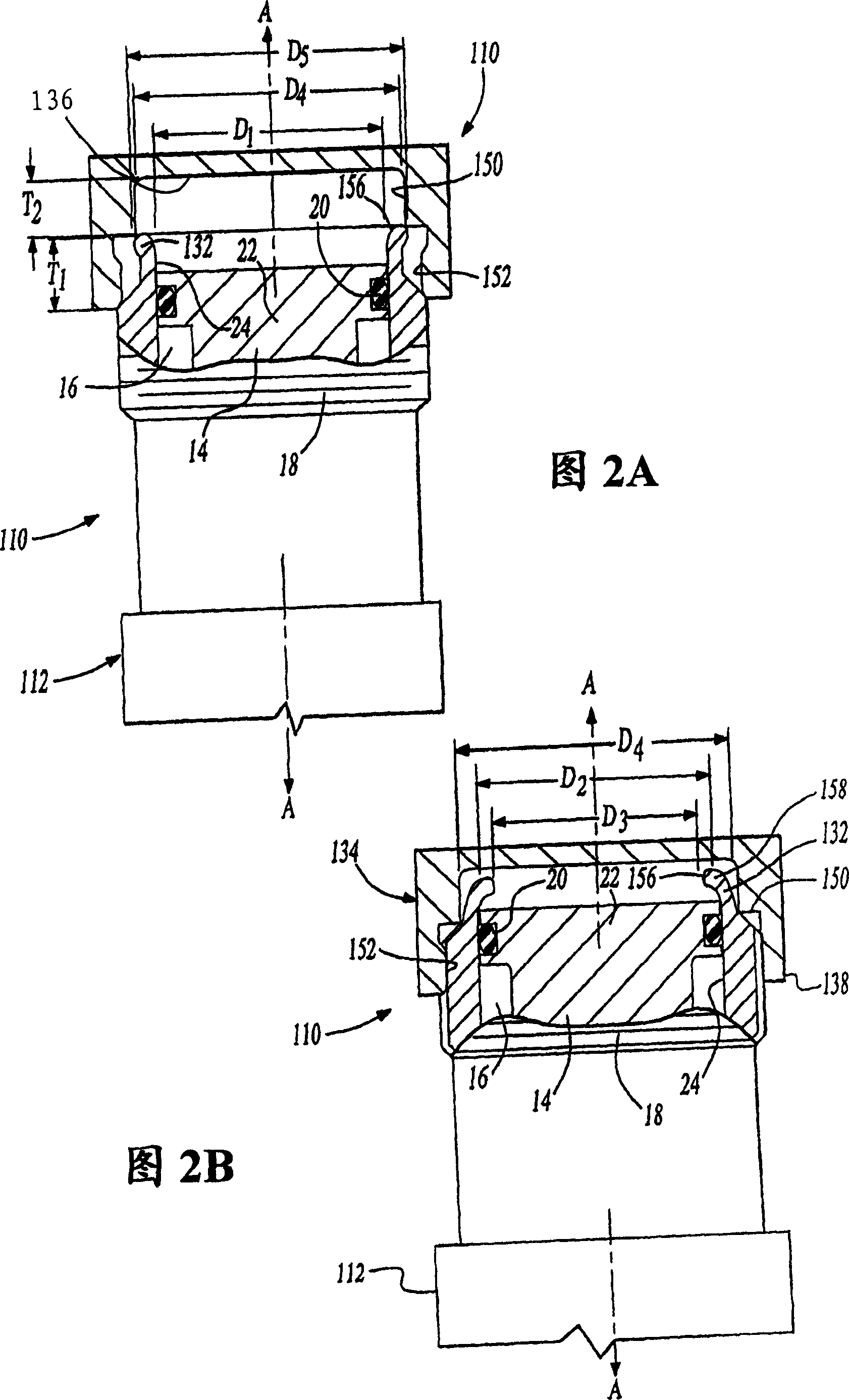

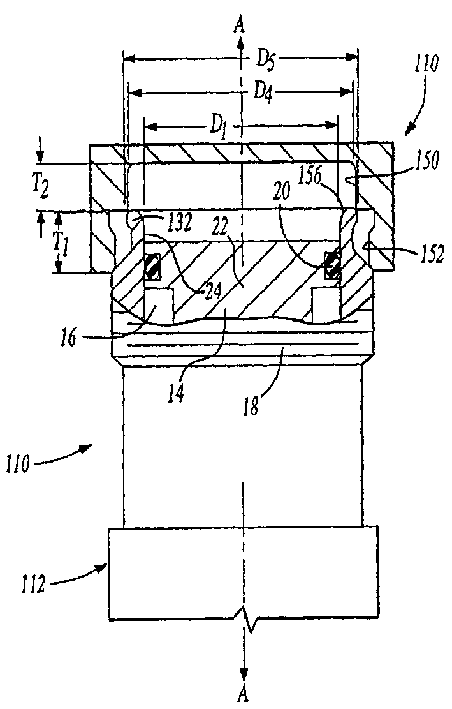

[0015] Air conditioner service valves 10 and 110 are shown in Figures 1, 2A and 2B. Generally, the service valves 10 and 110 include a valve body 12 and a valve stem 14 . A valve stem 14 is received within an interior cavity 16 of the valve body 12 and is supported by threads 18 . Depending on the direction of the threaded connection between the valve stem 14 and the valve body 12, the valve stem 14 is thus movable along the longitudinal axis A-A when it is rotated inwardly or outwardly, clockwise or counterclockwise. The O-ring 20 provides a seal between the top 22 of the valve stem and the inner surface 24 of the valve body.

[0016] The lumen 16 defines at its upper portion 26 an inner diameter D1 that closely corresponds to the outer diameter D2 of the valve stem top 22 . However, as seen in FIG. 1 , the inner diameter of the valve body cavity 16 at the upper portion 26 is generally constant. To prevent the valve stem 14 from moving upwards along the axis A-A beyond the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com