Ink-ribbon cartridge and thermosensitive printer using the same

A color ribbon box and ribbon technology, applied in the direction of ink ribbon box, printing, ink ribbon, etc., can solve the problems of poor image printing quality, poor printing quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

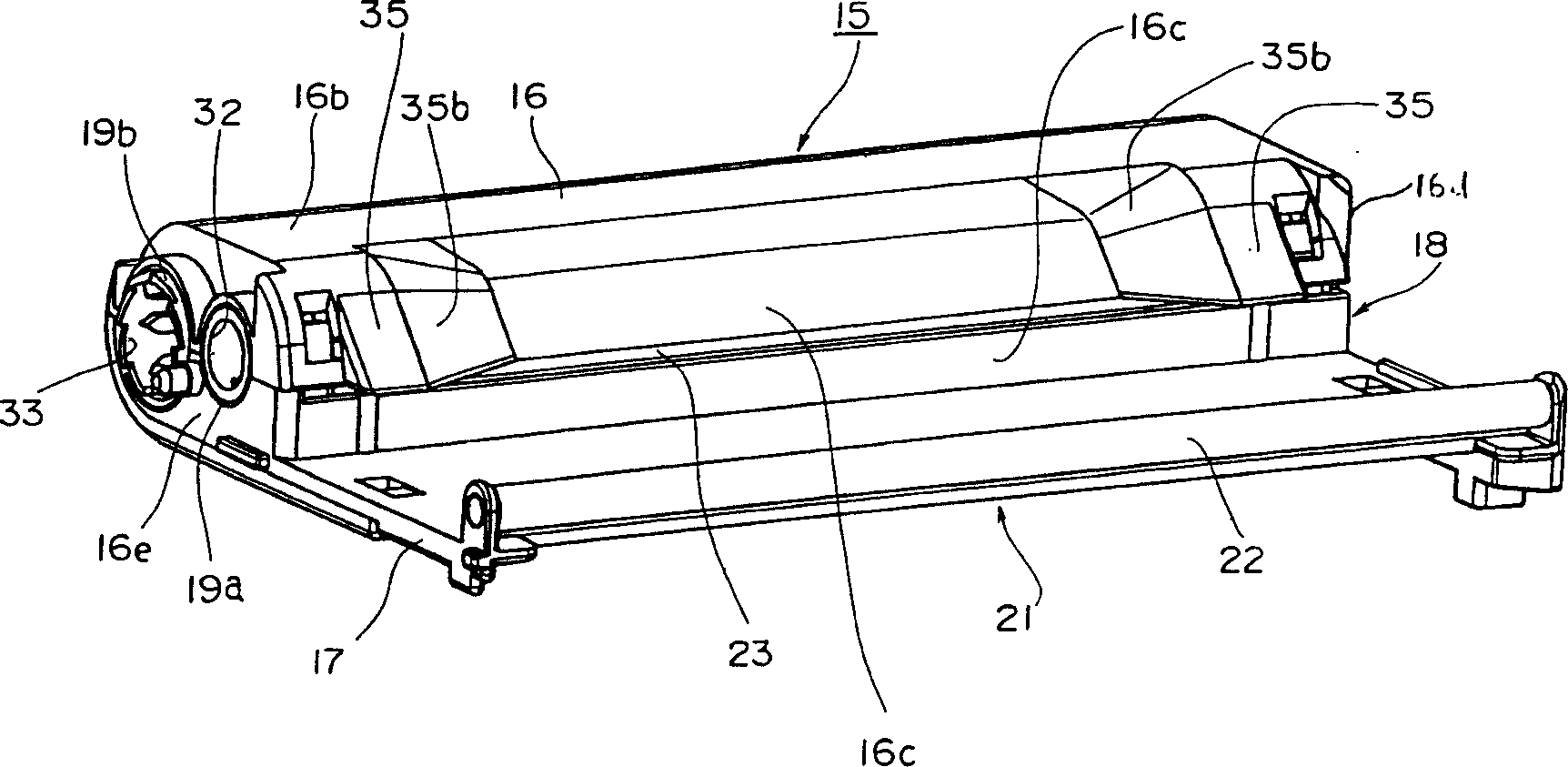

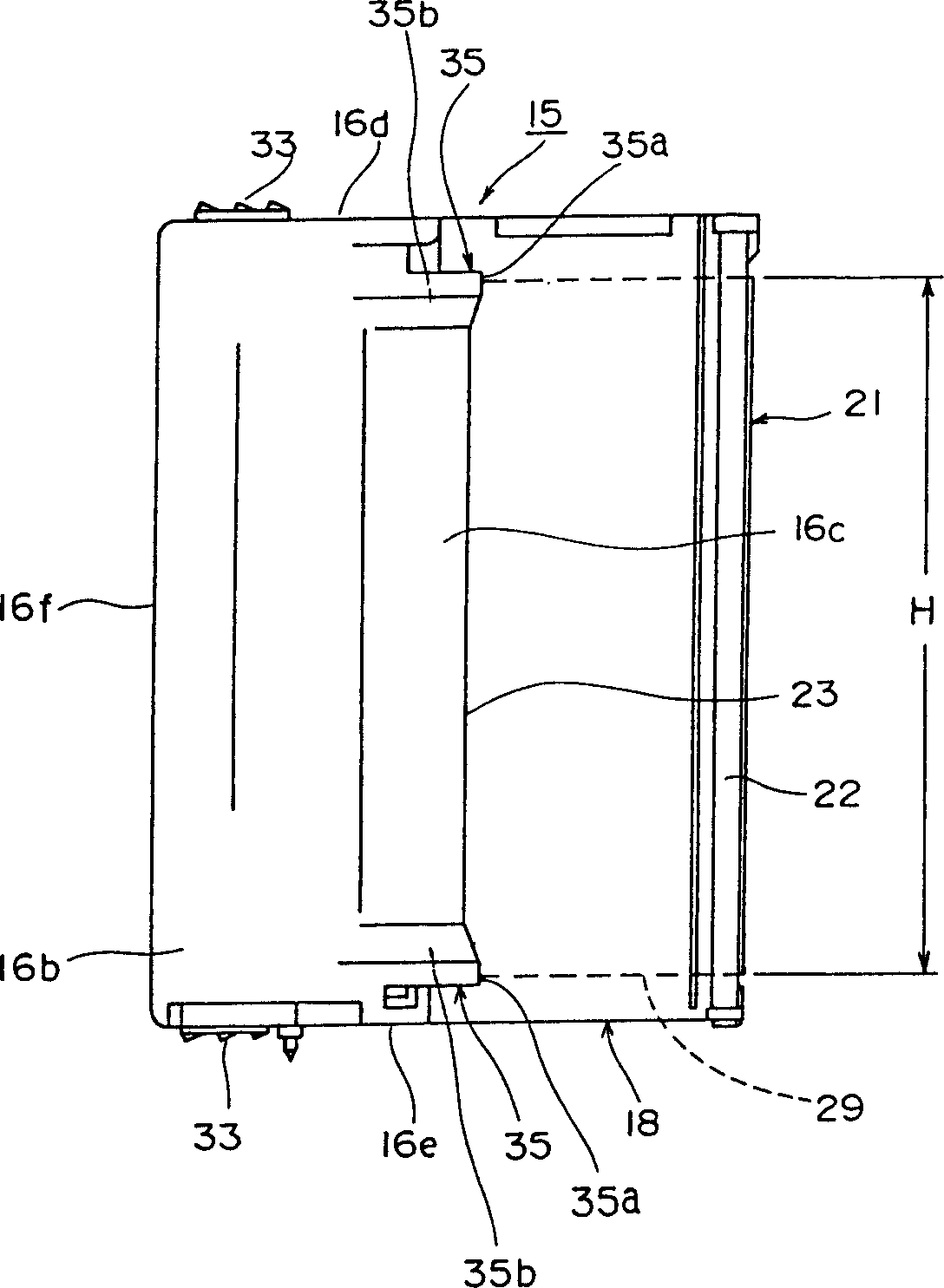

[0055] based on the following Figure 1 to Figure 1 0 illustrates an ink ribbon cassette according to an embodiment of the present invention and a thermal printer using the same.

[0056] Such as figure 1 as well as figure 2 As shown, the ink ribbon cassette 15 has a top plate 16a and a bottom plate 16b arranged opposite to each other, a wall plate 16c arranged between the top plate 16a and the bottom plate 16b and connected to the bottom plate 16b, and a hollow color ribbon cassette inside. Body part 16. And, from the top plate 16a of the ink ribbon cassette body part 16 in one direction ( figure 2 The right direction) is provided with a ribbon guide 17 extending.

[0057] Also, in the ink ribbon cassette body portion 16, a pair of substantially elliptical side wall plates 16d, 16d are provided to face each other. Two through-holes 19a, 19b having different diameters are respectively formed in these side wall plates 16d, 16d. In addition, the ink ribbon cassette body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com