Printing point offset correction control method and printing device thereof

A technology of offset correction and control method, which is applied in the printing timing of printing device to eliminate dot offset field, and can solve the problems of printing quality degradation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

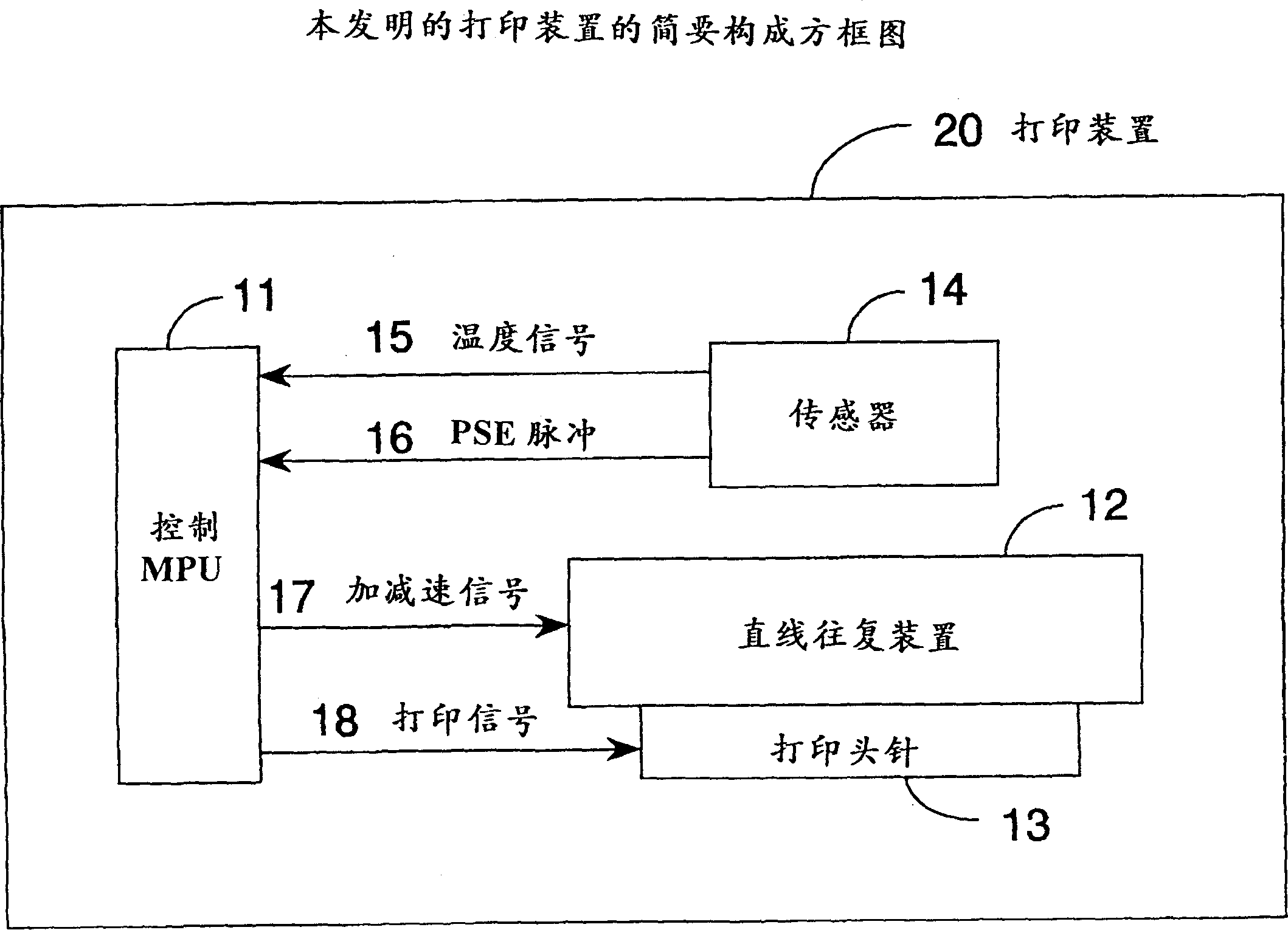

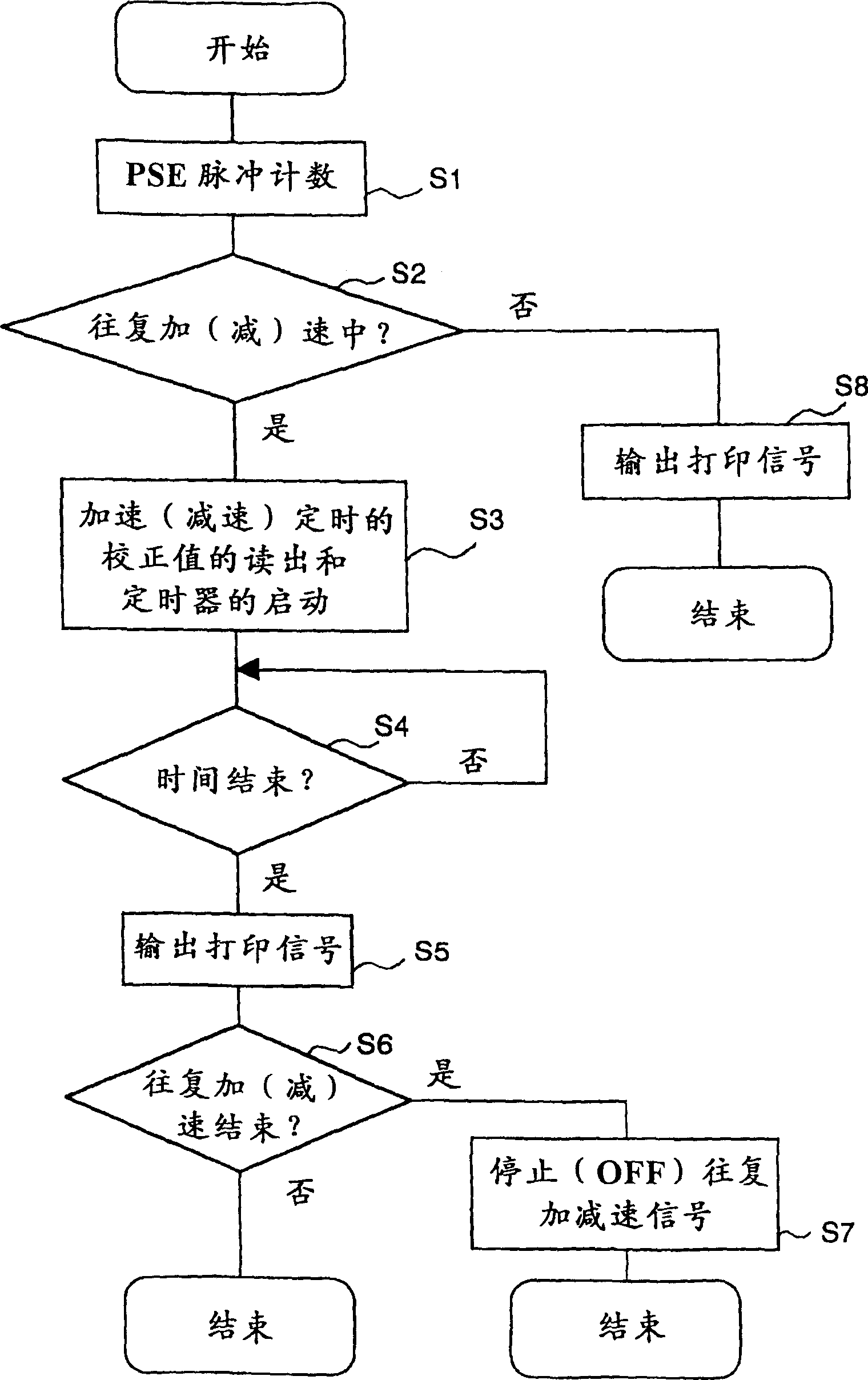

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below according to the embodiments shown in the drawings. However, the present invention is not limited thereto.

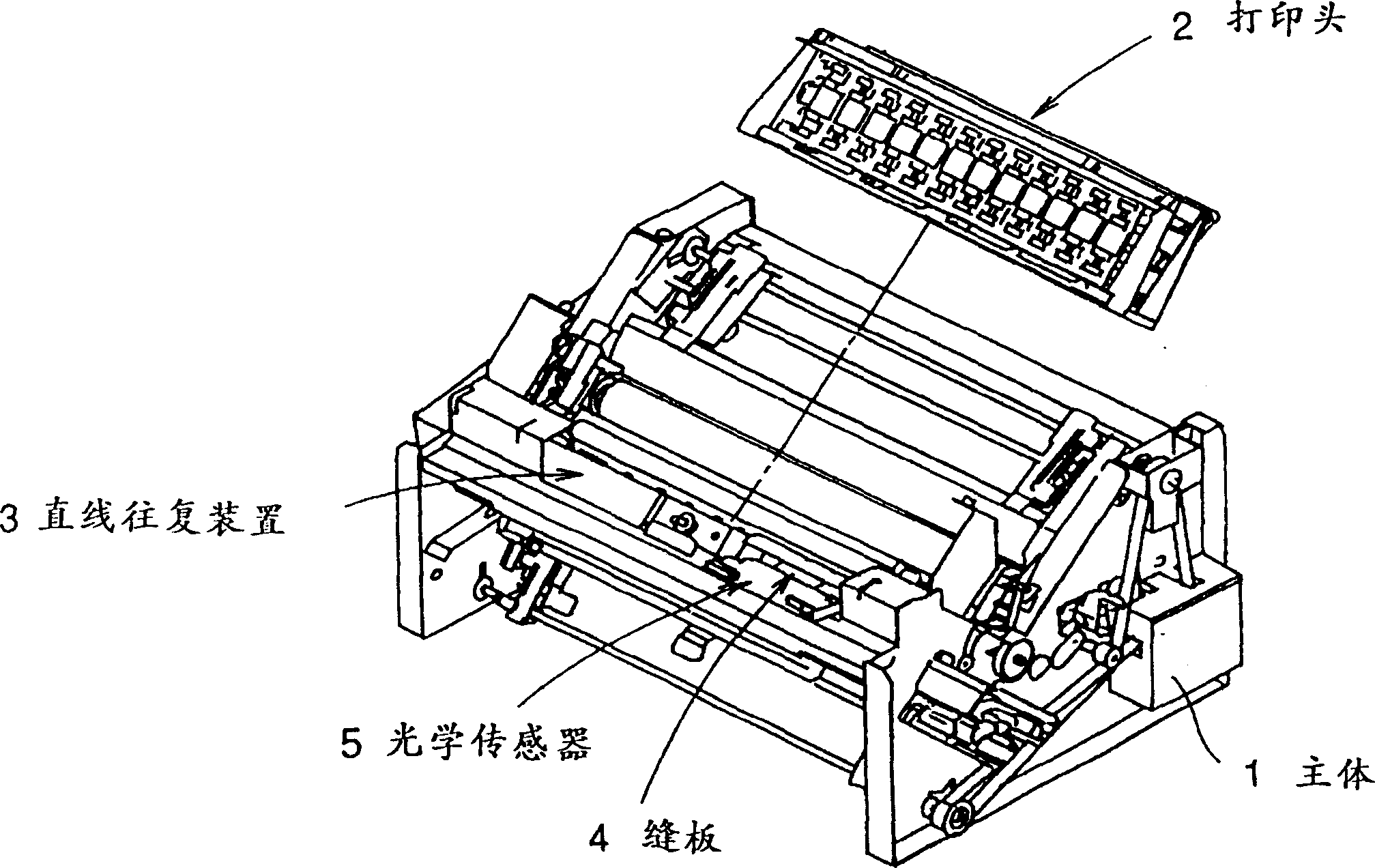

[0045] exist figure 1 A perspective view of the printing apparatus of the present invention is shown in .

[0046] exist figure 1 Among them, the print head 2 is mounted on the linear reciprocating device 3, and the linear reciprocating device 3 is movable in the left and right directions along the axis extending in the left and right direction of the printing device main body 1 (direction perpendicular to the conveying direction of the printing paper). device 3.

[0047] On the print head 2, a plurality of print head needles are arranged side by side in the left-right direction. For example, with 12 to 18 printhead pins. A yoke, a permanent magnet, and a slit plate 4 are arranged on the linear reciprocating device 3, and an optical sensor 5 composed of a pair of light-emitting LEDs and a photosensiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com