Small substrate baffle for organic luminous film plating machine with automatic recognition function

A technology of automatic identification and coating machine, applied in the field of machinery, can solve problems such as costing a lot of time and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

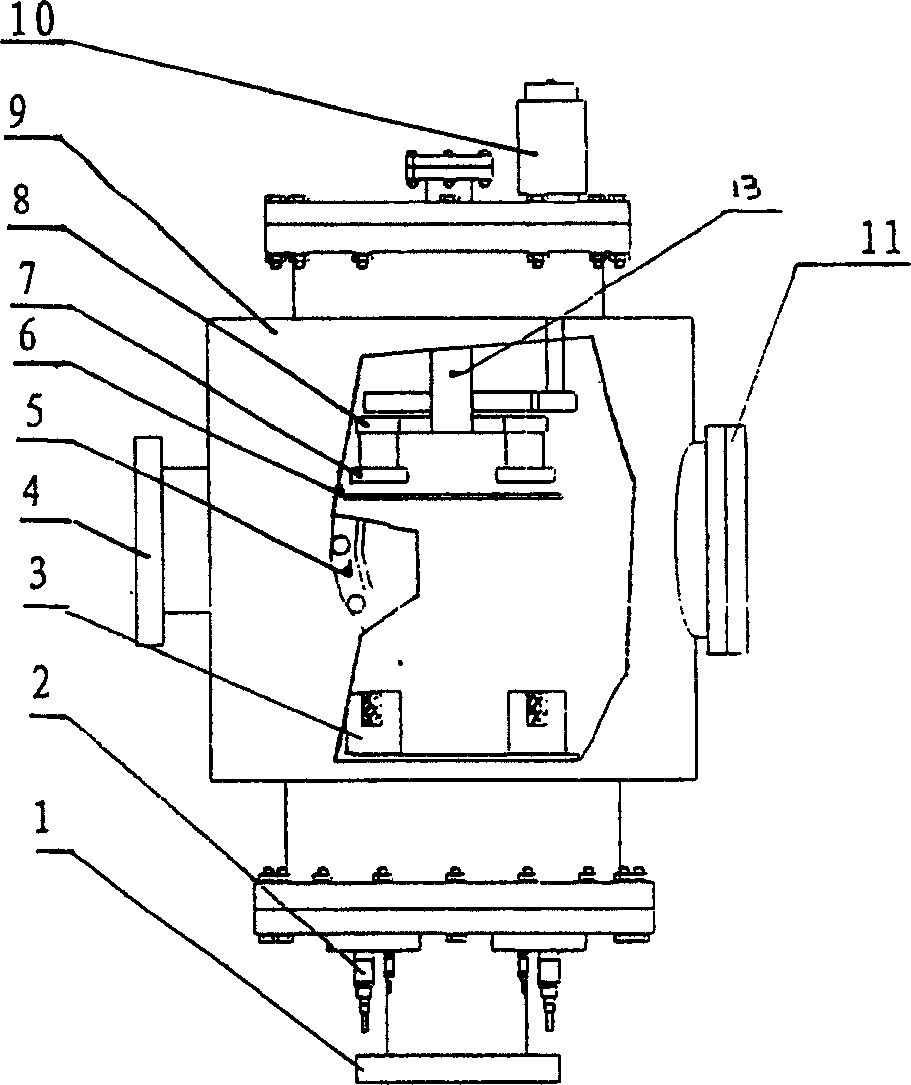

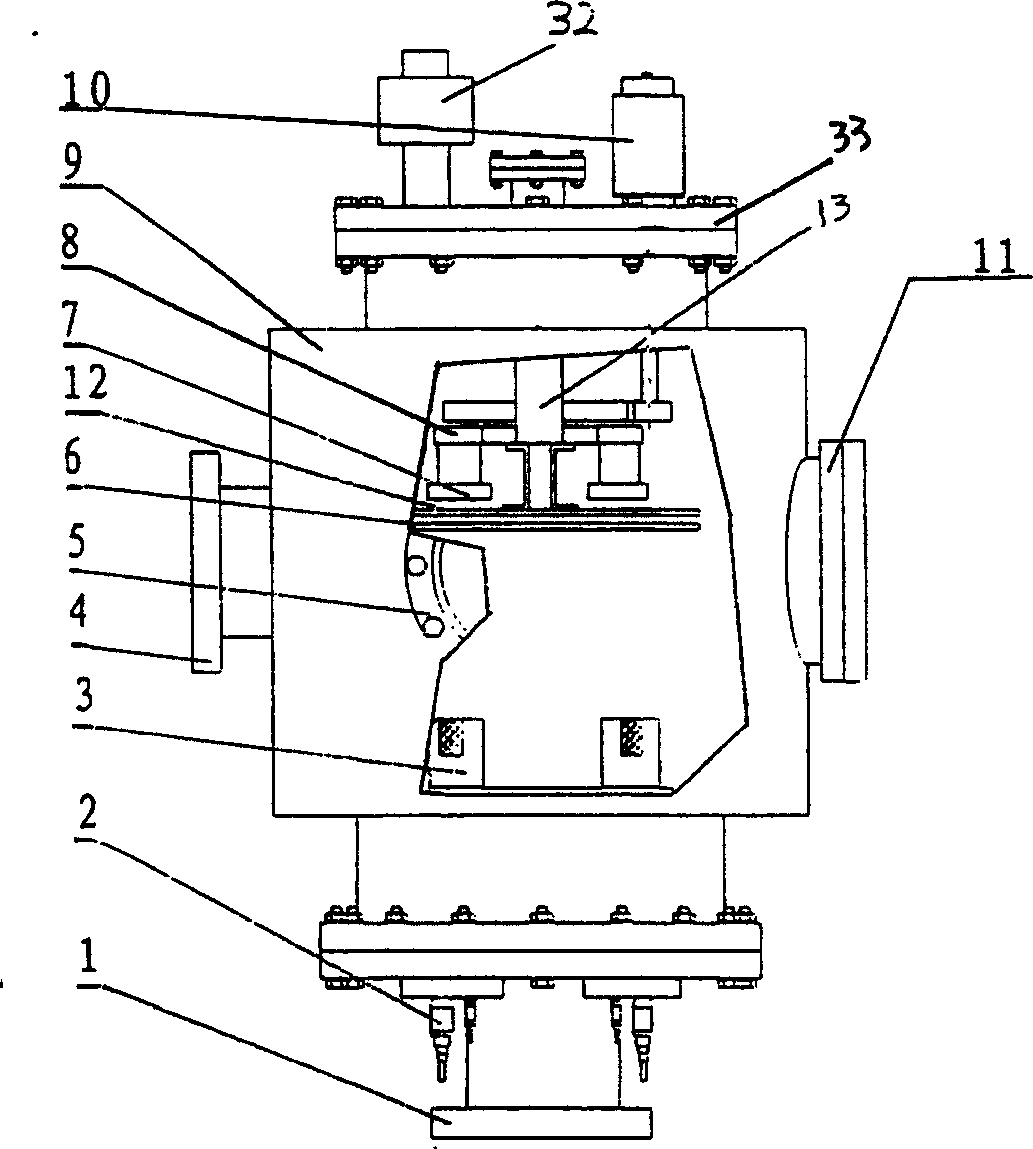

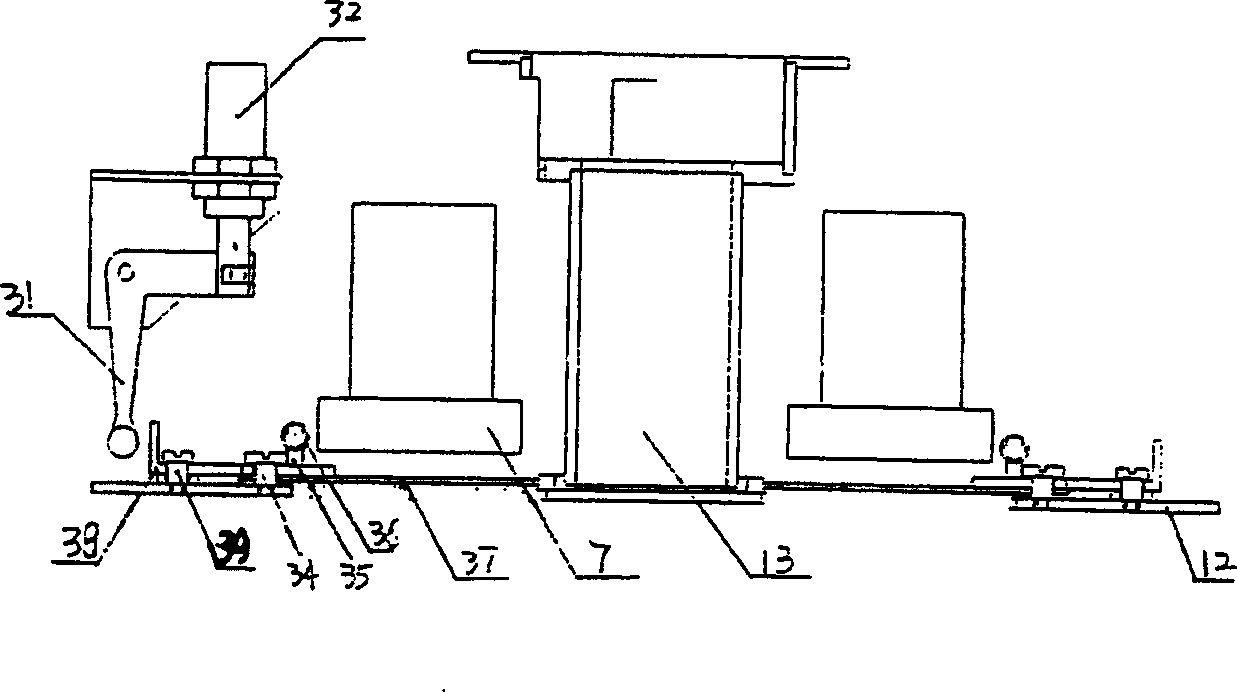

[0015] Specifically, as attached figure 2 As shown, the present invention is provided with a supporting plate 12 between the substrate 7 on the planetary rotating substrate holder 8 and the large substrate baffle plate 6, and the supporting plate 12 is installed on the revolution axis of the planetary rotating substrate holder 8 13, rotates synchronously with 8 on the planetary rotary substrate holder. Small substrate baffles are installed on the supporting plate 12, the position of each small baffle corresponds to the hole position of each substrate, and each small substrate baffle can control the coating on the corresponding substrate in one experimental cycle. Like this, just can be provided with a plurality of substrates (>=2) on the planetary rotary substrate holder 8 of the same vacuum chamber, correspondingly a plurality of small baffles are set on the supporting plate 12, and a plurality of small baffles are arranged around the common The rotating shafts (13) are arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com