Motorcycle brake jaw-force detection table

A technology for brakes and motorcycles, applied in vehicle testing, force/torque/power measuring instruments, machine/structural component testing, etc., can solve problems such as inaccuracy and unscientific test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] specific implementation plan

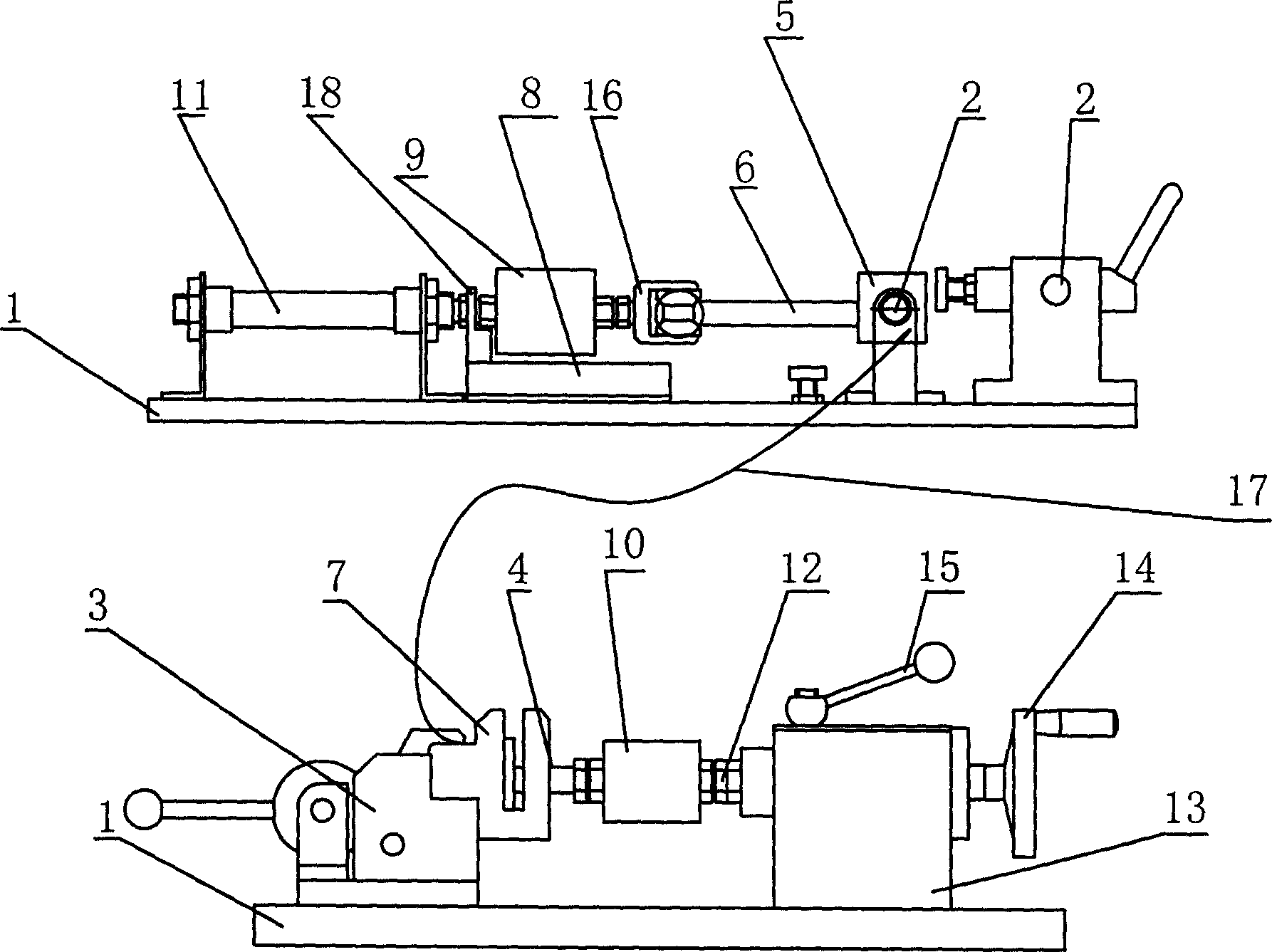

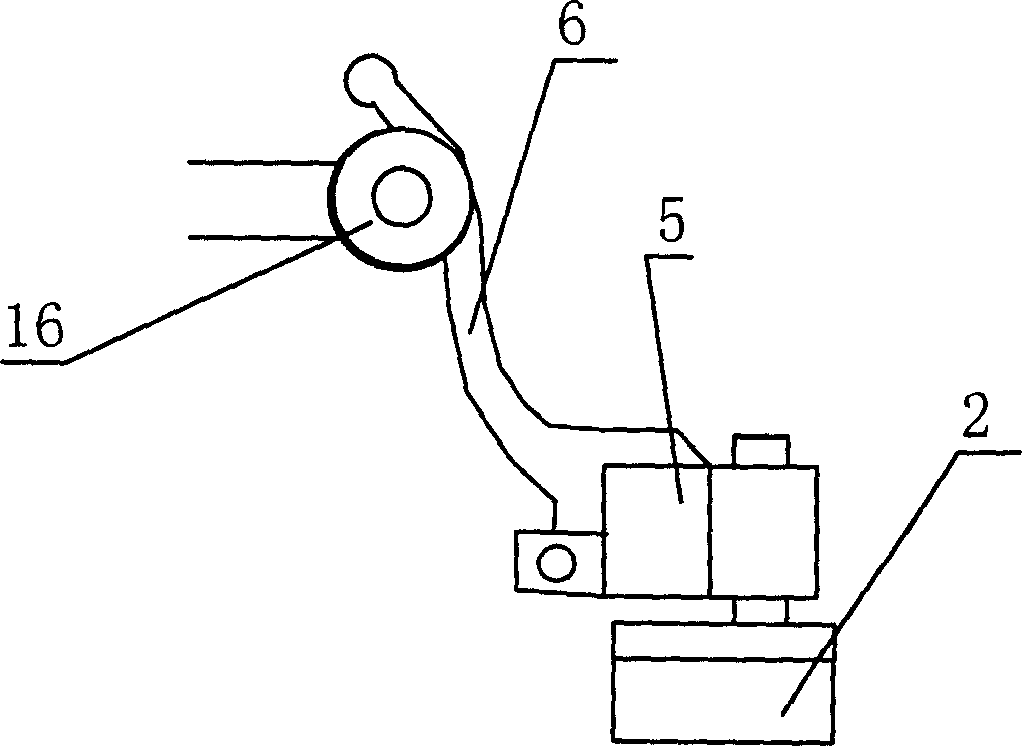

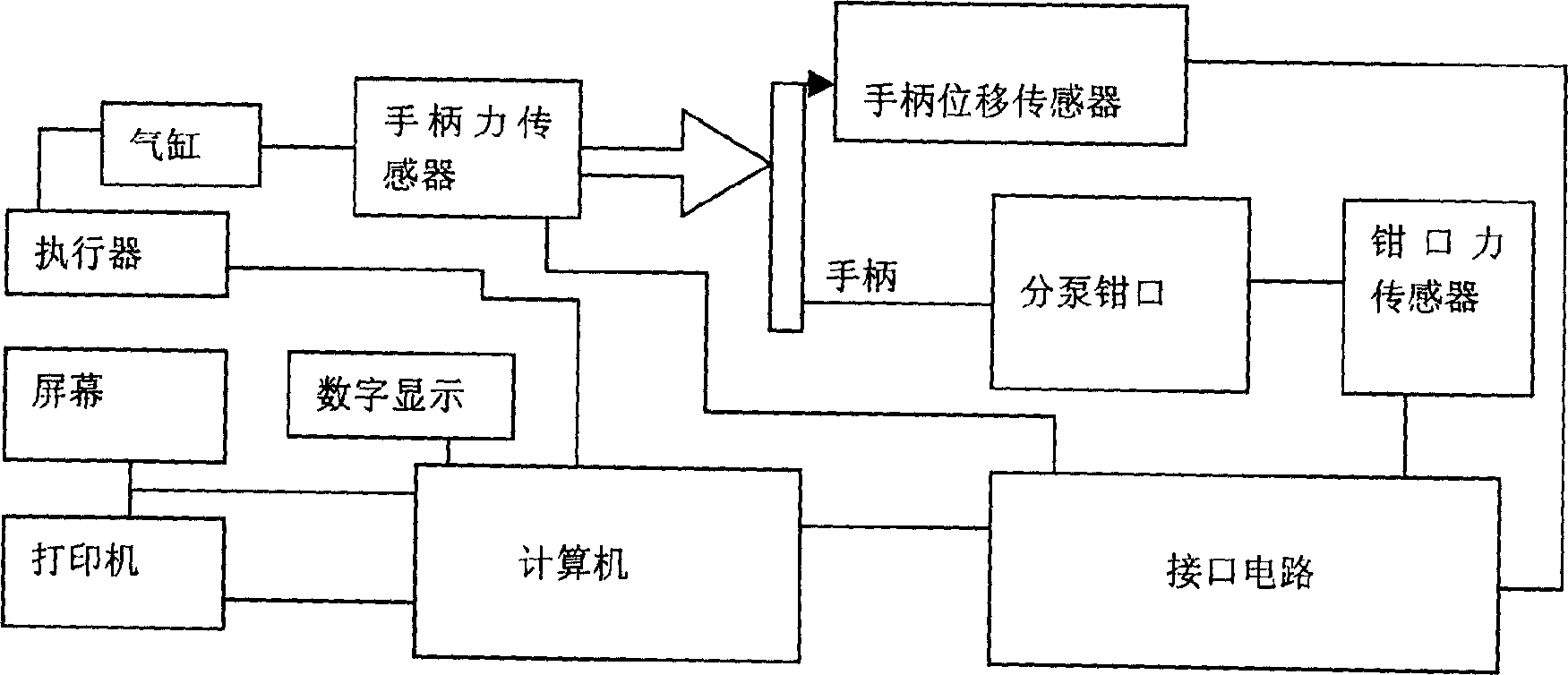

[0026] Such as figure 1 , 2 Shown embodiment of the present invention, it comprises computer and test bench main body; Test bench main body comprises: frame 1, the clamp 2 that is used to fix the handle body 5 of tested piece, the jaw that is used to fix tested piece and pump The clamp 3 of the body assembly 7, the power mechanism for pushing the handle 6 on the handle body 5, and the ejector rod 4 pressed on the jaws. The handle body fixture 2, the jaws and the pump body assembly fixture 3, the power mechanism, and the ejector rod 4 are all arranged on the frame 1. Power mechanism is cylinder power mechanism 11, and it is controlled by computer, and cylinder power mechanism 11 promotes handle by handle, is provided with handle pressure sensor 9 between power mechanism and handle and pushes roller 16. The power mechanism is also provided with a displacement sensor 8 , and the coupling piece 18 of the displacement sensor 8 is arranged be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com