Ink-jet image forming method and device

An image, predetermined image technology, applied in the direction of inking device, printing, etc., can solve the problems of deterioration of black image quality, increased power of drying parts, poor black reproducibility, etc., and achieve the effect of preventing image quality deterioration and improving printing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] [Embodiment 1]

[0091] -Overall configuration of the device-

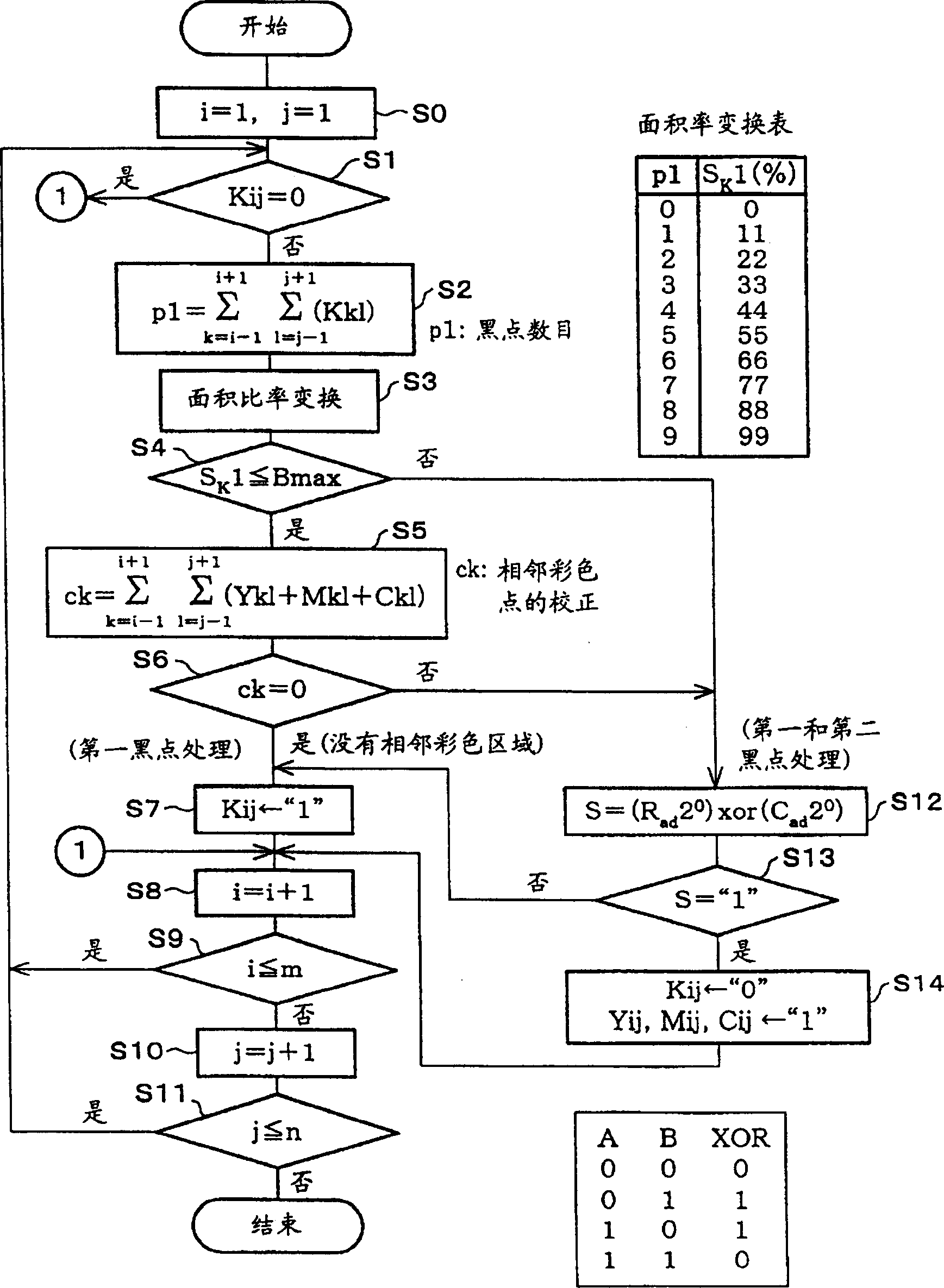

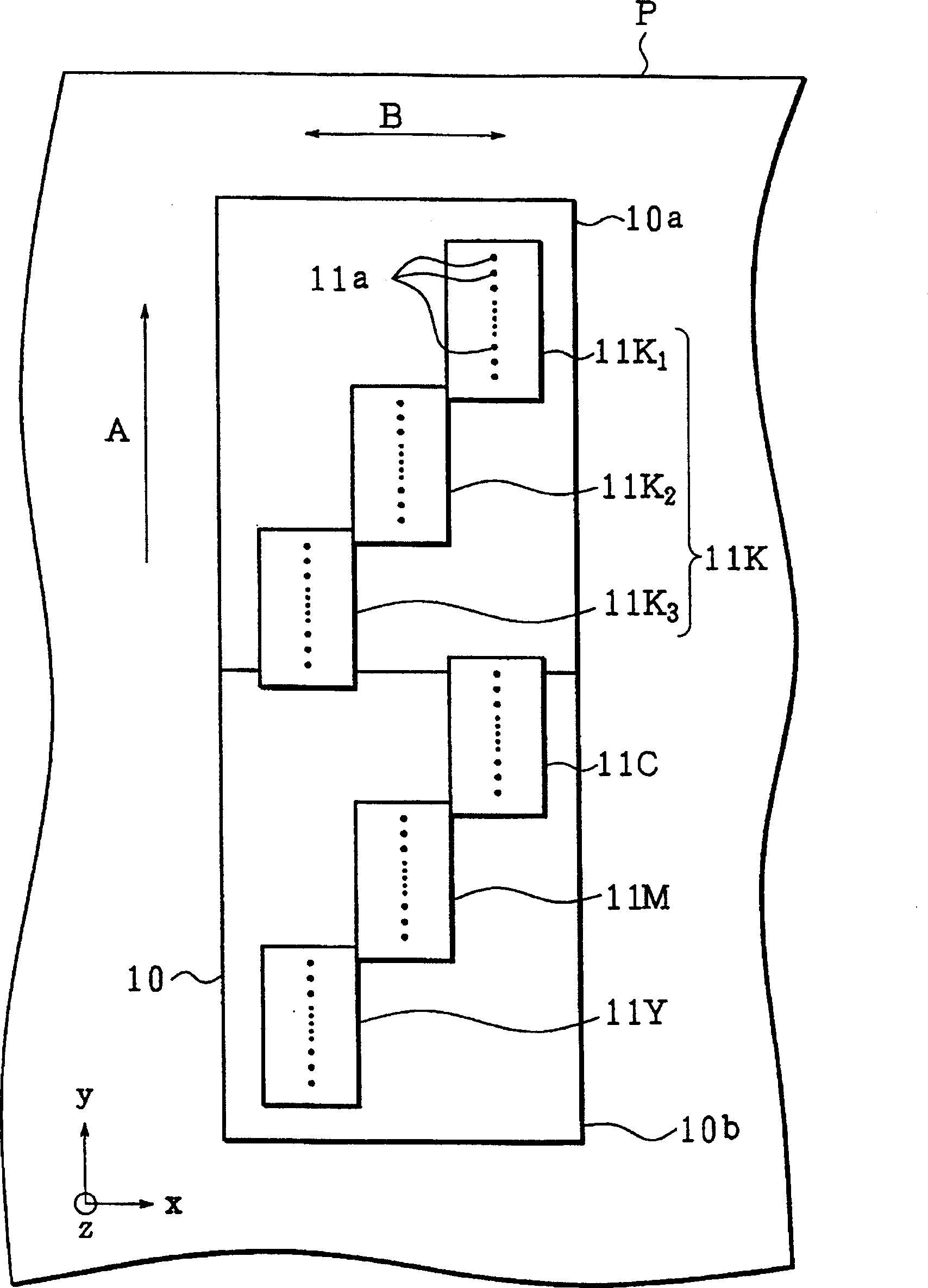

[0092] Refer below Figure 1 to Figure 18 One embodiment of the present invention will be described.

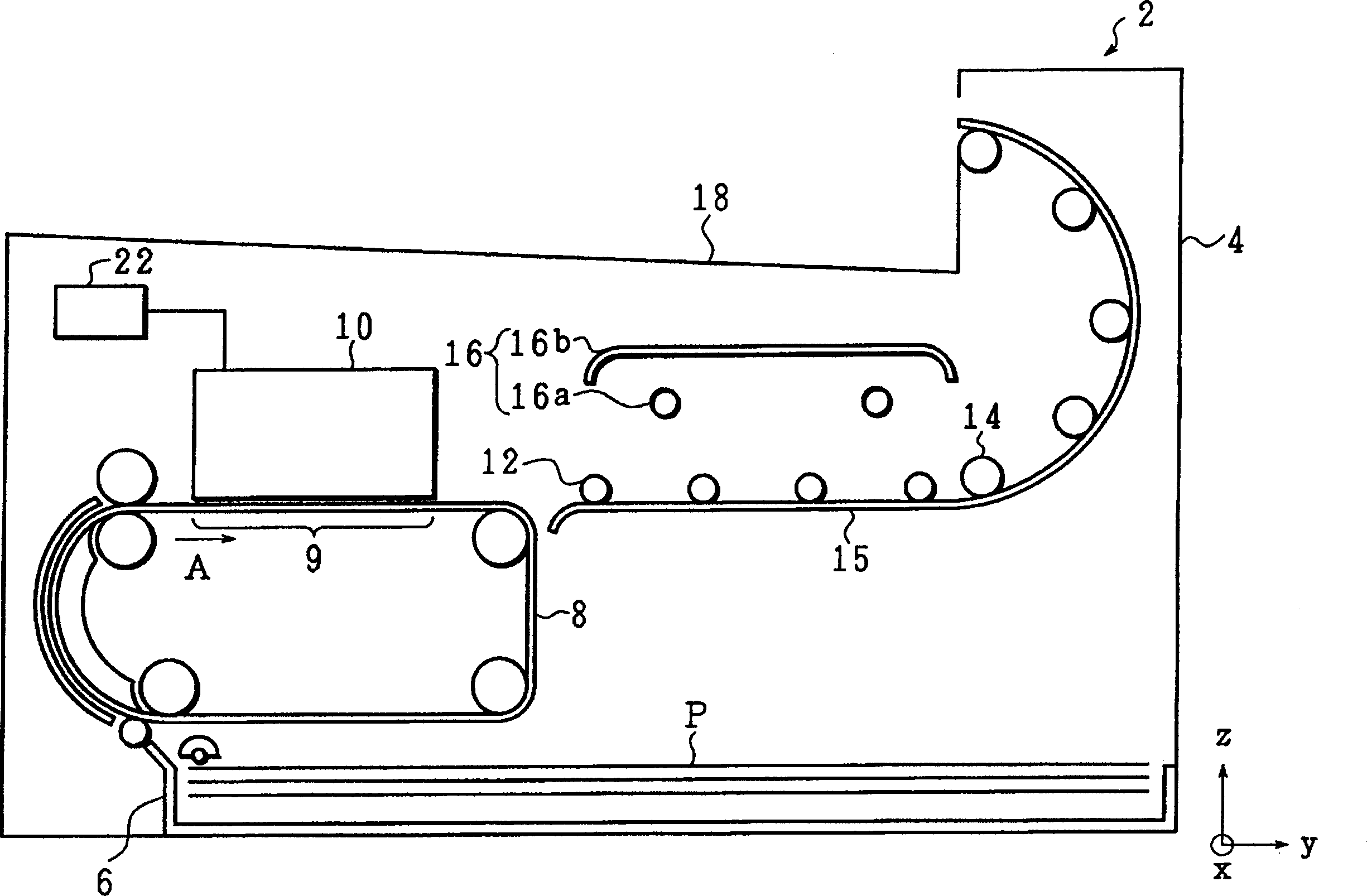

[0093] Refer below figure 2 The structure of the color inkjet printer 2 applicable to the dot forming method of the inkjet system according to this embodiment will be described. figure 2 It is an internal configuration diagram showing the inside of the color inkjet printer 2 according to the present embodiment viewed from the side direction.

[0094] Inside the casing 4 of the color inkjet printer 2 are provided with a paper feed carriage 6, a conveying belt 8, a printing head (ink printing head) 10, a star roller 12, a conveying roller 14, a conveying path 15 and a drier 16, Moreover, a paper discharge bracket 18 is also provided on the top of the casing 4 . In addition, the color inkjet printer 2 has a control unit (control unit) 22 for controlling various components, and a temperature detection u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com