Scroll-type compressor

A technology of scroll compressors and compression chambers, applied in the direction of rotary piston machines, rotary piston pumps, mechanical equipment, etc., can solve problems such as unequal flows

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

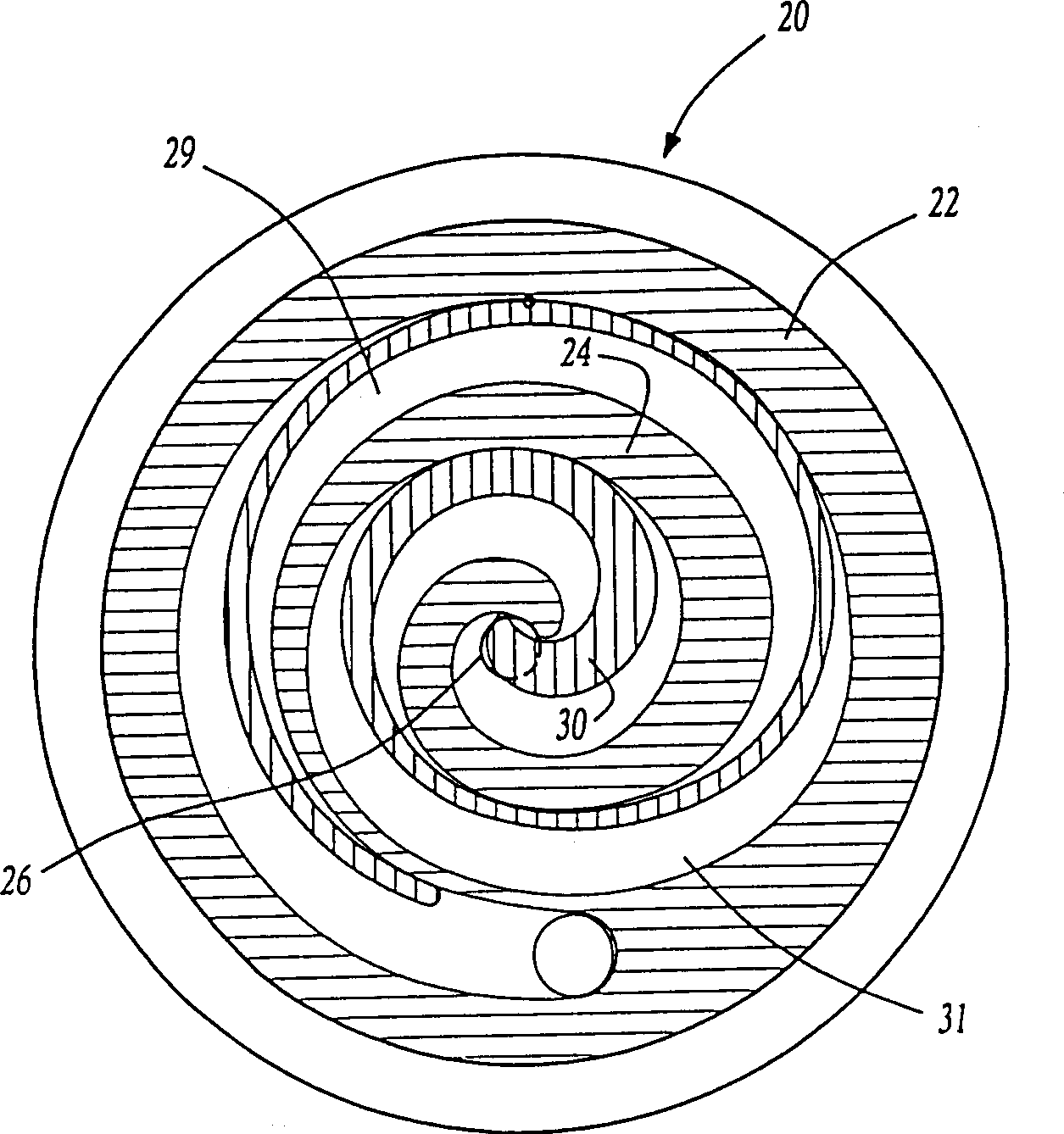

[0026] Figure 1A A prior art scroll compressor pump unit 20 having a non-rotating scroll member 22 with a scroll 24 is shown. As shown, scroll 24 begins at a generally central point 6 and extends generally along a helical line to an outer location. As also shown, orbiting scroll 30 cooperates with scroll 24 and defines a plurality of compression chambers such as 29 and 31 .

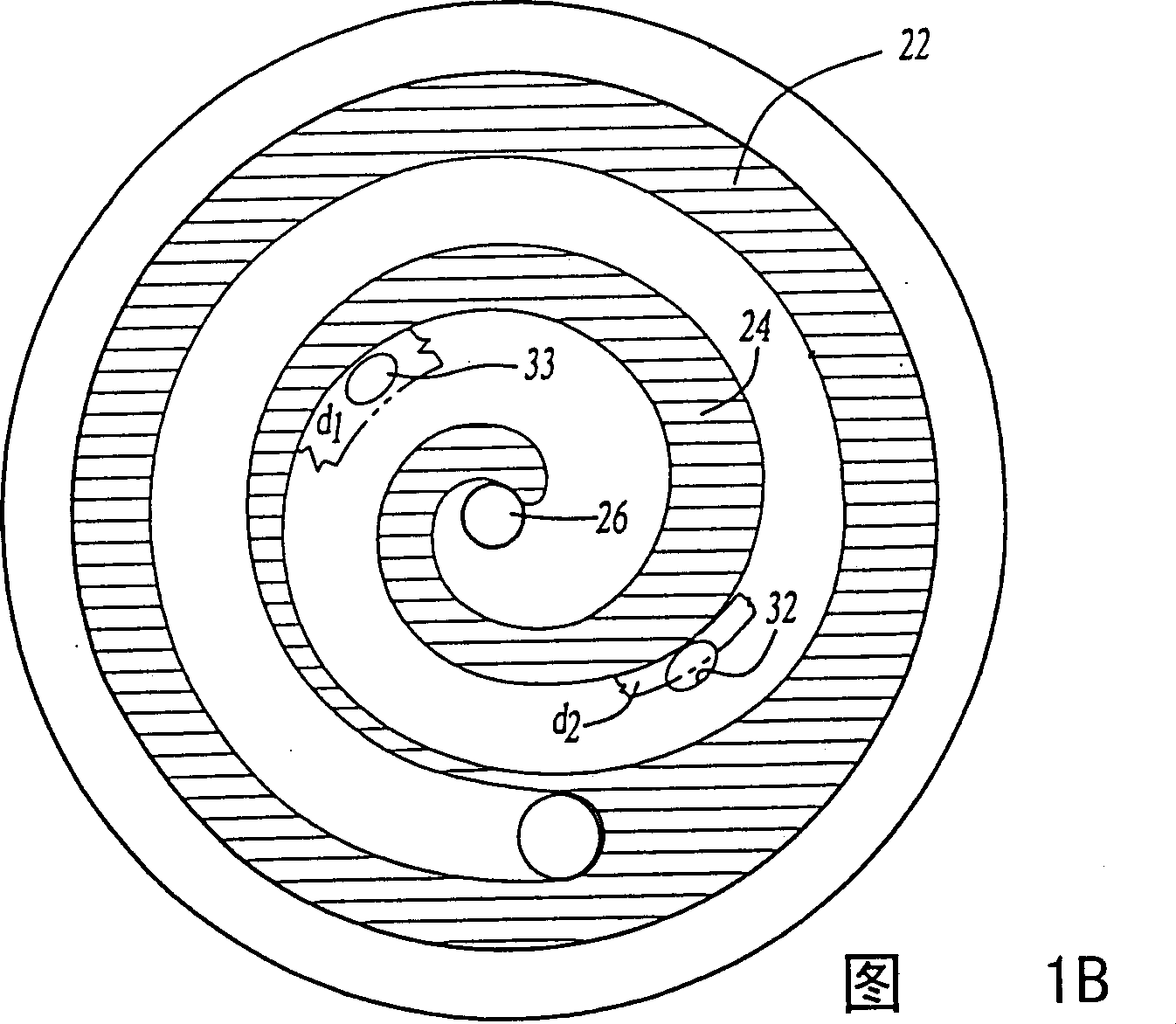

[0027] As shown in FIG. 1B , injection ports 33 and 32 selectively communicate with compression chambers 31 and 29 , respectively.

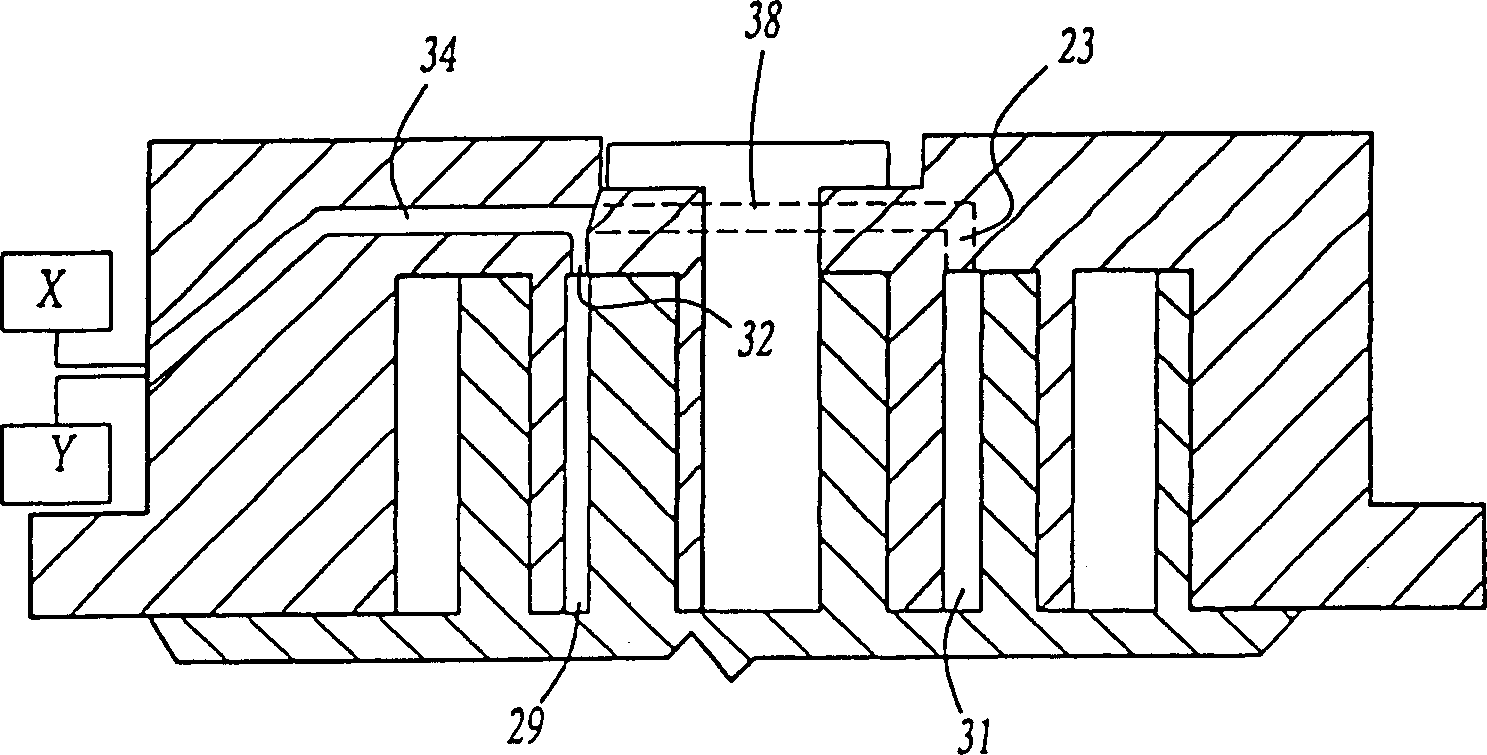

[0028] Such as figure 2 As shown, passage 34 communicates with injection port 32 . The passage 34 communicates with the injection port 33 through a passage 38 . Channel 38 is often curved to avoid interference with the discharge opening. For this reason, the channel is shown with dashed lines. Passage 34 communicates within an economizer cycle (x) or with an unloader valve (y) or both, as schematically shown.

[0029] Depend on figure 2 It can be seen that the flui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com