Flying negative pressure air bearing slider with divided negative pressure pockets

A slider, air technology, applied in the hydrodynamic spacing of the head, instruments, support heads, etc., can solve problems such as adverse performance and influence, and achieve the effect of small actual contact area, constant suspended gram load, and stable floating state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

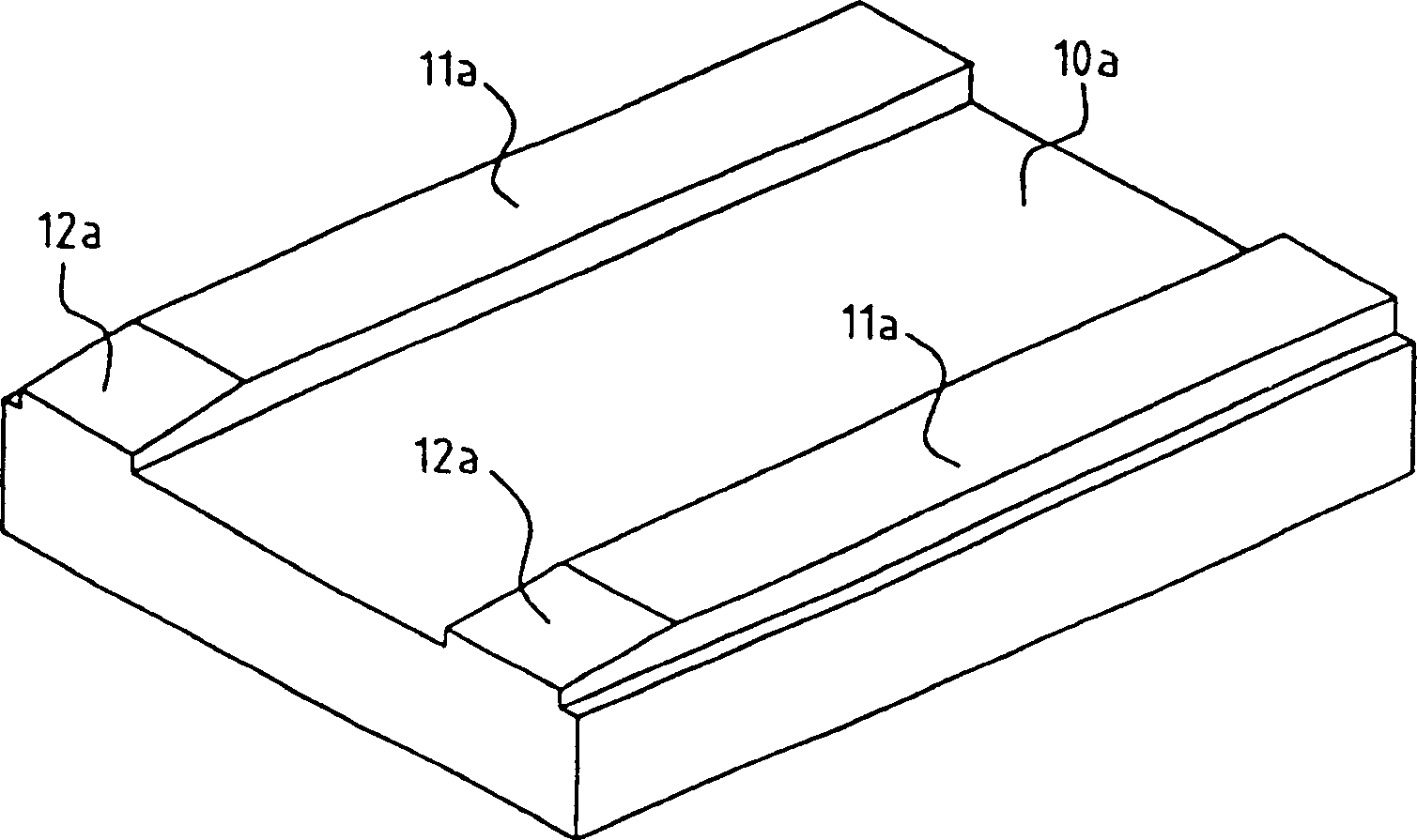

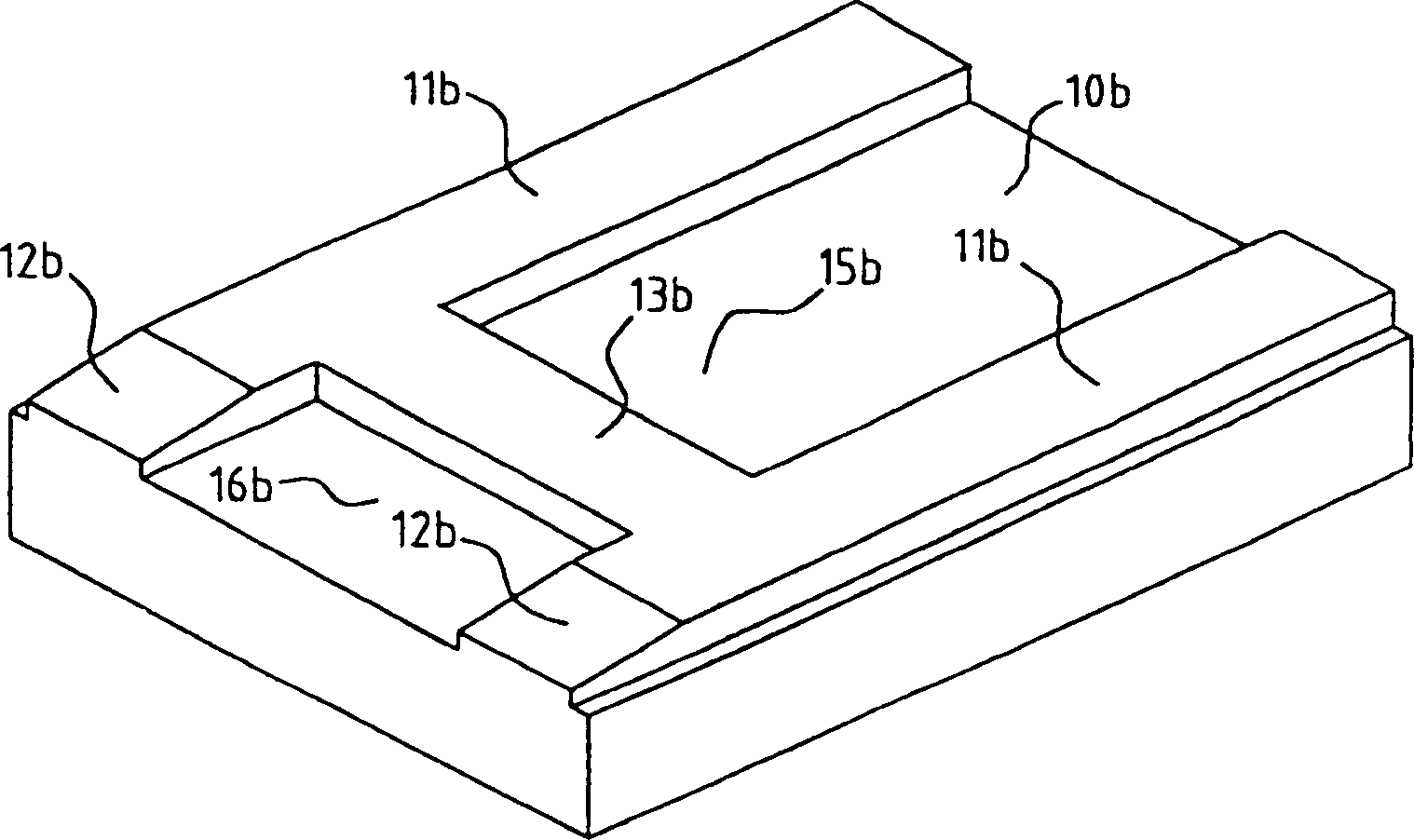

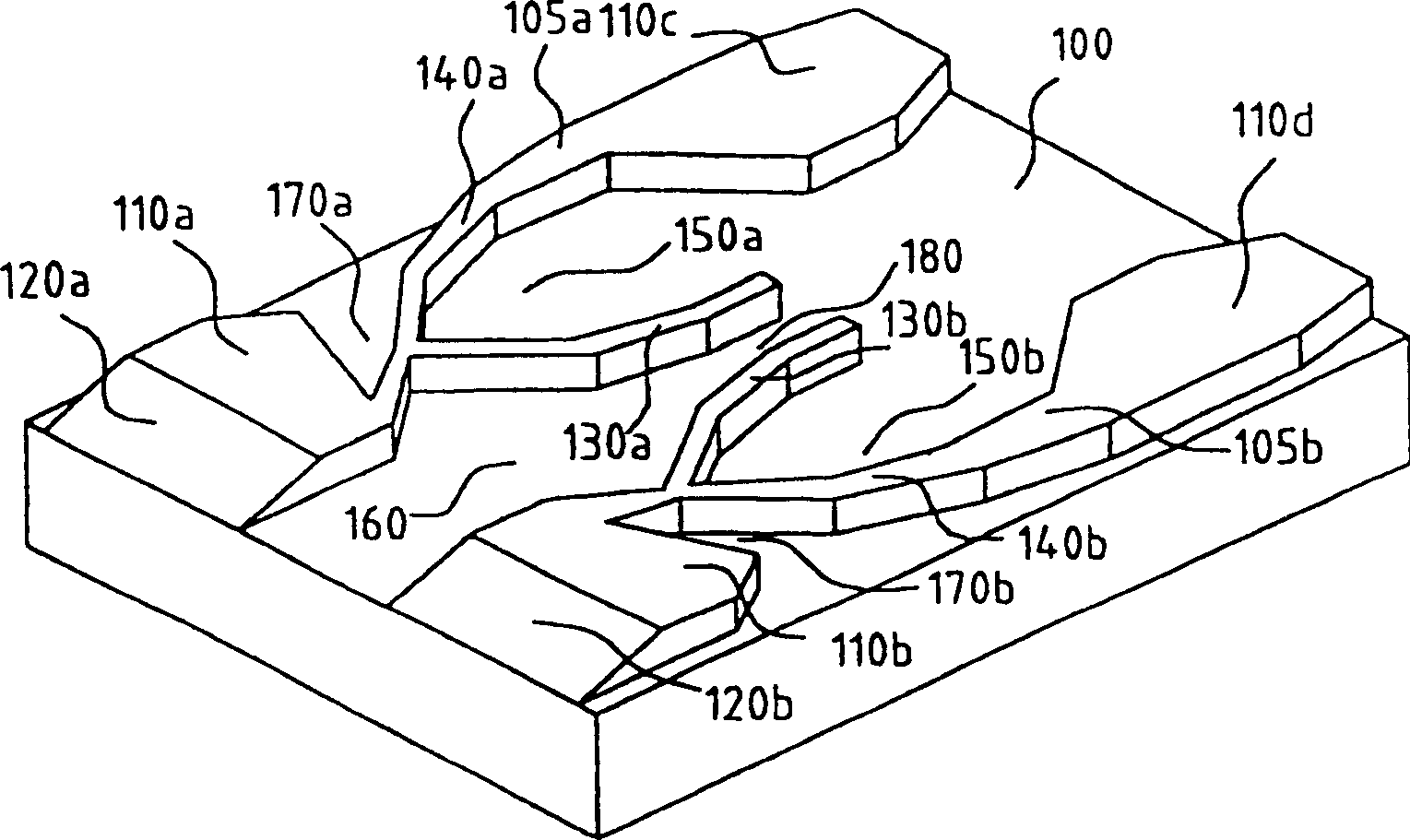

[0036] The present invention generally relates to floating air bearing sliders with spaced negative pressure pockets or cavities. image 3 is a bottom perspective view of the improved floating NPAB slider of the present invention, Figure 4 A bottom plan view of the modified slider embodiment is shown.

[0037] The following discussion is conditioned on the floating air bearing slider body 100 floating above the surface of the recording disk during the relative rotation of the recording disk. The slider body 100 has a main surface facing the magnetic disk surface, and on the main surface, rail and groove patterns are formed. The major surface has a leading edge (front), a trailing edge (rear), a first side and a second side, wherein the leading edge is upstream of the trailing edge spaced relative to the longitudinal axis of the slider body, the longitudinal direction Corresponds to the tangential rotation direction of the recording disk. The first side is spaced apart from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com