Inkjet printer for printing on goods

A technology of inkjet printers and commodities, applied in typewriters, printing, etc., can solve the problems of inkjet printer failure, poor printing quality, and incomplete fluids, etc., and achieve the effect of preventing quality reduction and sealing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

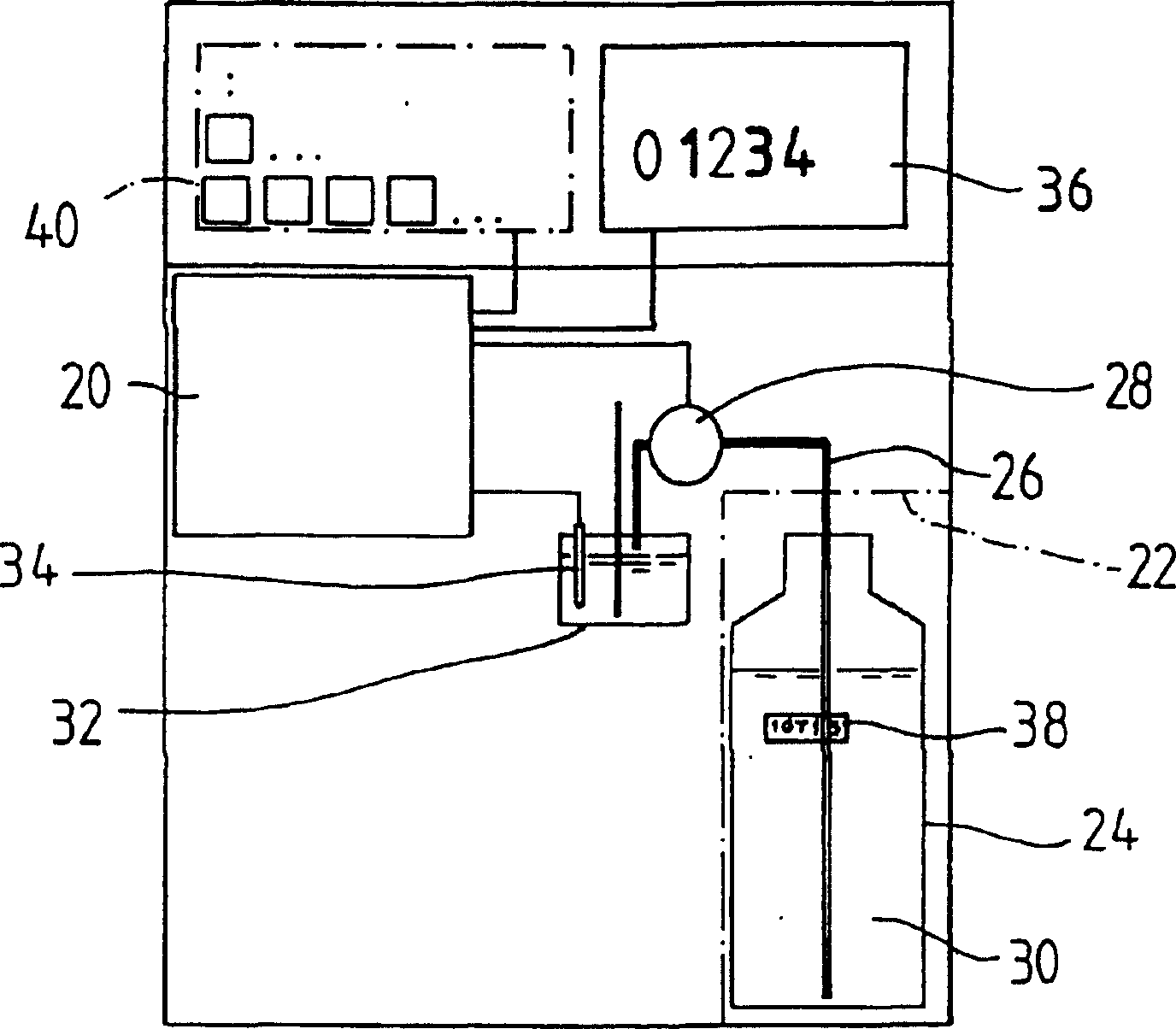

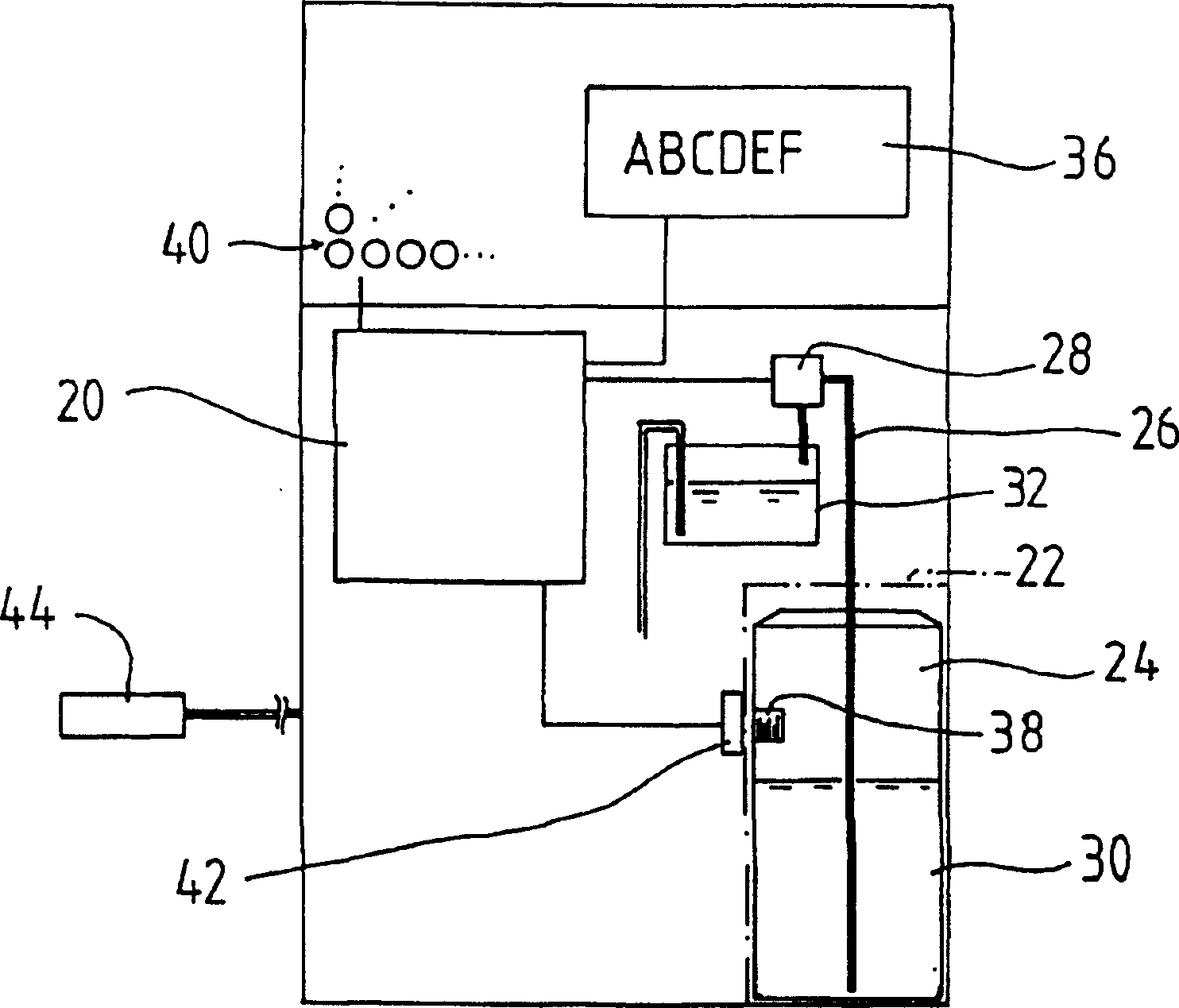

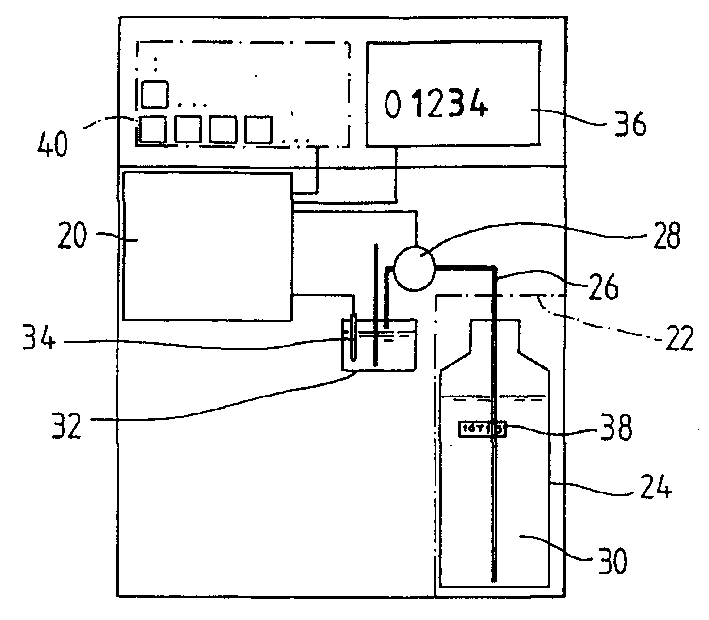

[0020] The inkjet printer has a computer 20 which controls the internal operating program. In addition, it is provided with at least one storage bottle 24 accommodated in the holding device 22, said bottle containing a fluid such as a paint or a solvent. In the present invention, the storage bottle 24 used is the simplest kind. It doesn't have a light-blocking window to detect height, doesn't have any mechanical parts, and doesn't have a distinctive stop. The fluid 30 contained in the storage bottle 24 is withdrawn by means of a suction tube 26 using a pump 28 and delivered to an intermediate container 32 fitted therein. exist figure 1 In the preferred embodiment, the intermediate container is equipped with a device 34 designed to detect the amount of fluid 30 withdrawn from the storage bottle 24. For this purpose, a sensor 34 is arranged in the intermediate container 32 , which can be, for example, a capacitive sensor. Its output is connected to a computer. When it is de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com