Method and device for cutting to length strips or sheets in rolling or transport line

A technology of transverse cutting and rolling line, which is applied in the direction of shearing and forming blank devices, shearing devices, knives for shearing machine devices, etc., and can solve problems affecting the operation of the strip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

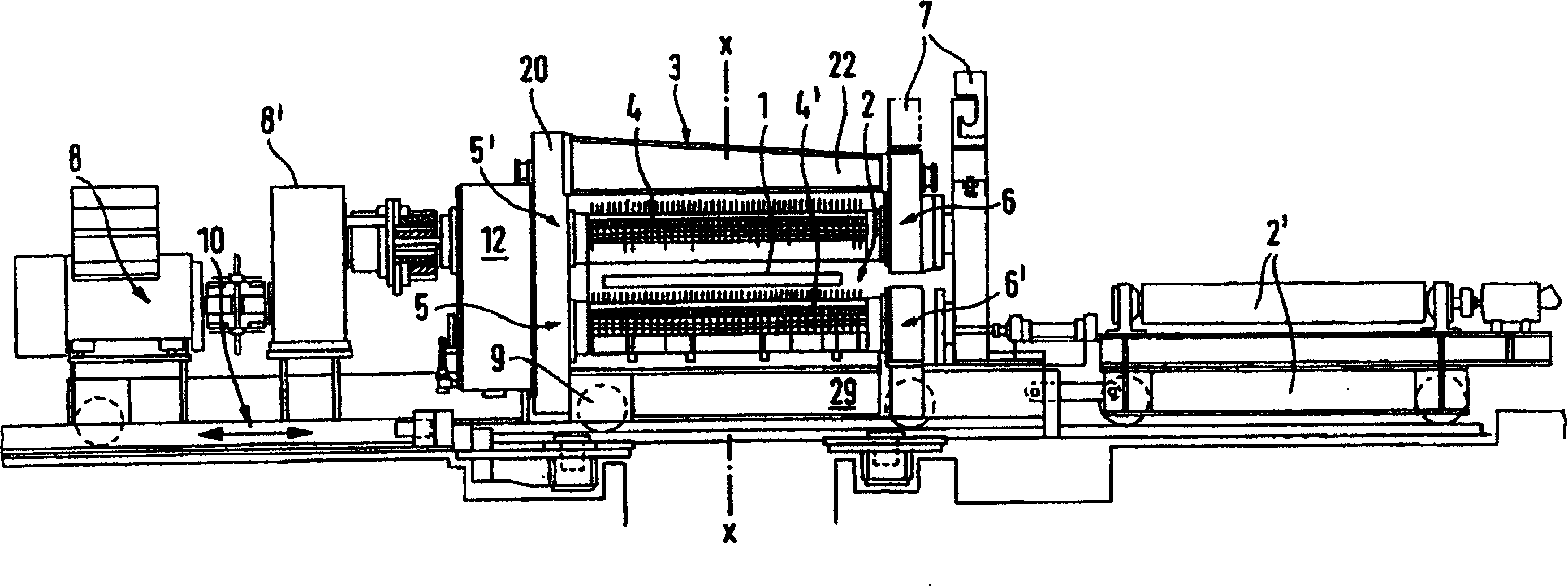

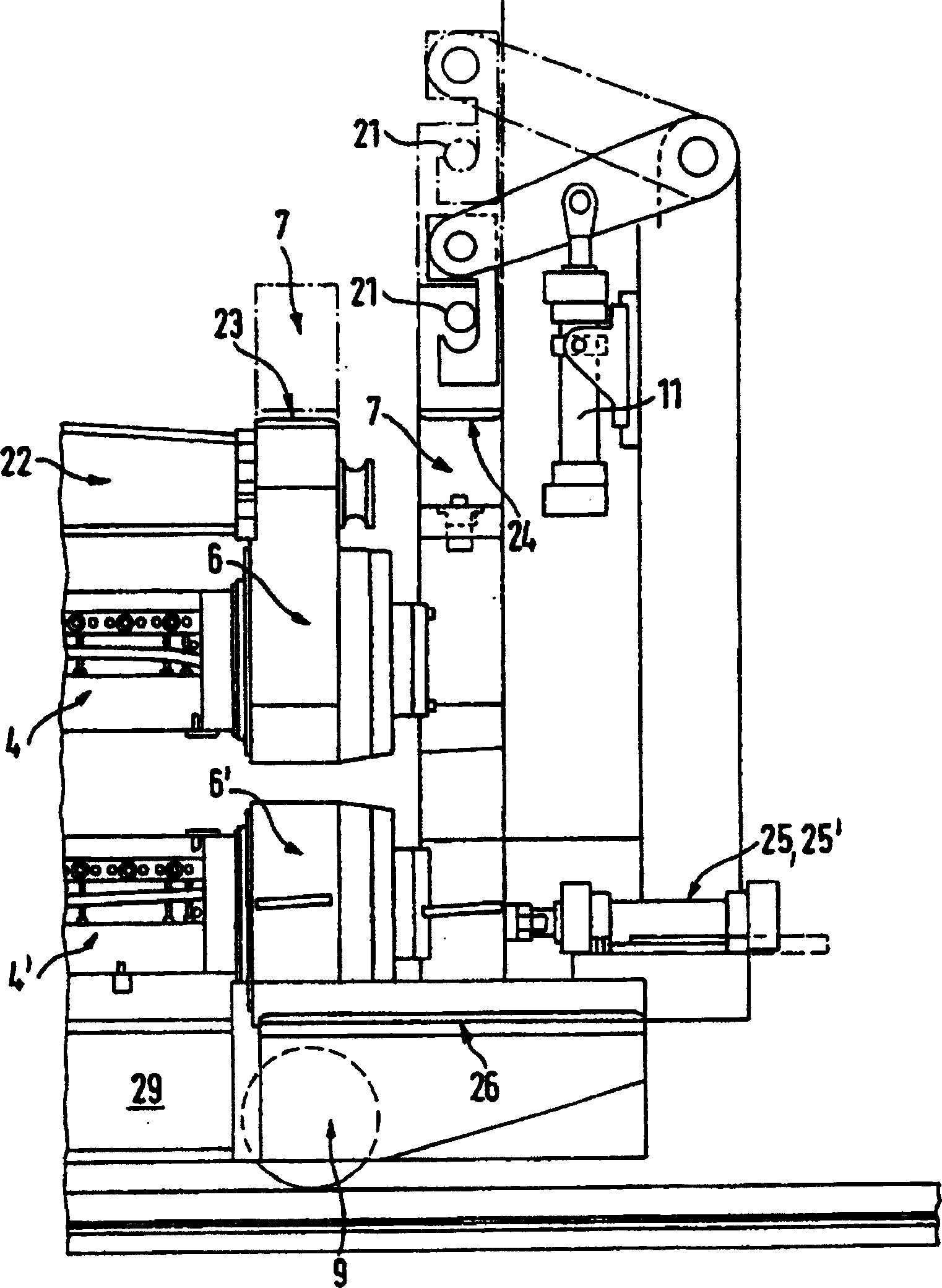

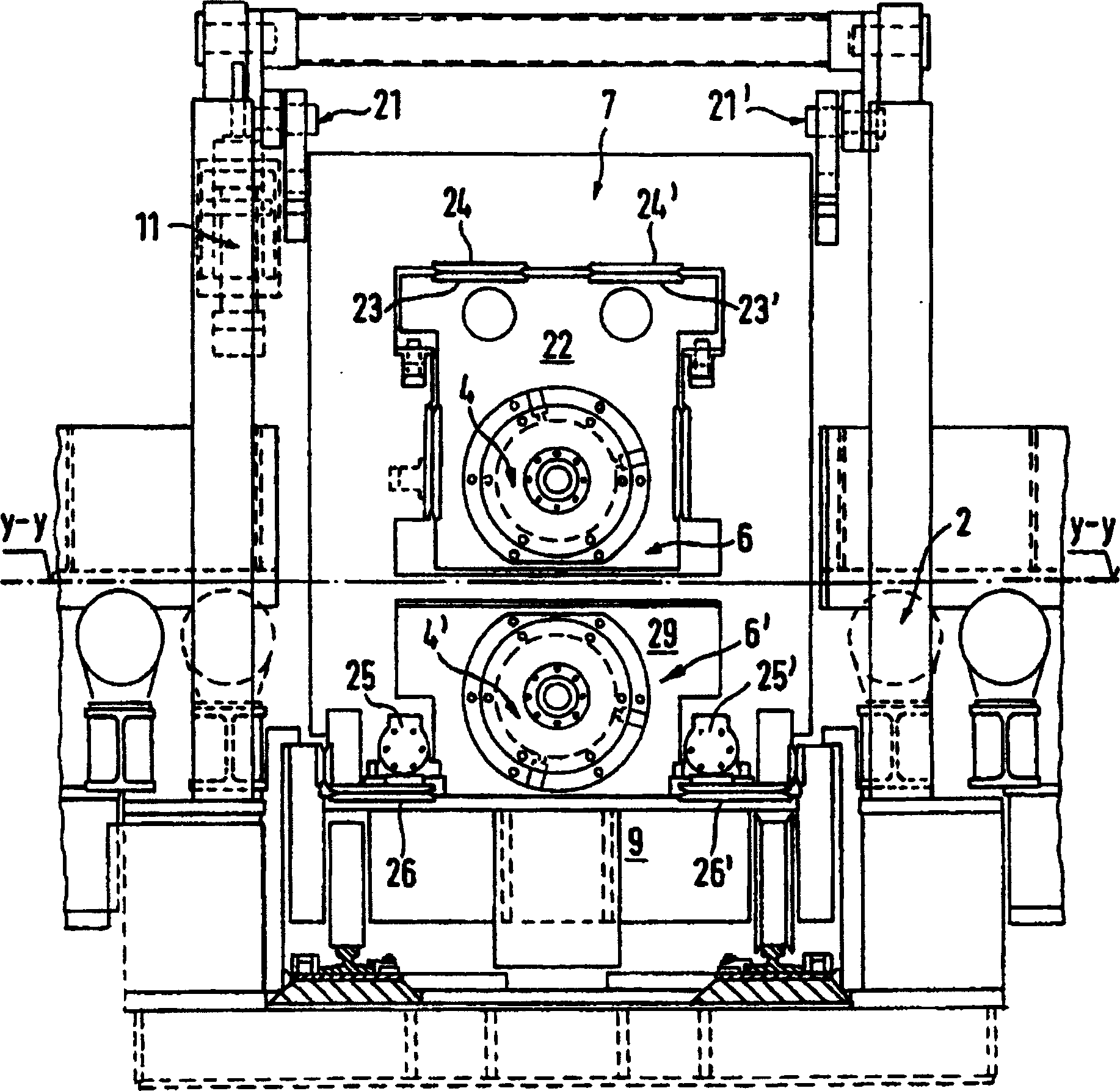

[0026] figure 1 The device shown is used for transverse cutting of plate strip 1 on rolling line or conveying line x-x, particularly on roller table 2, wherein shearer 3 is in a position about to cut, it has still The cantilevers 22, 29 of its frame 20 in the open state. The shearing machine has a drive 8 with a reduction gear 8 ′ and a synchronous drive 12 fastened to a frame 20 . The shearer with its drive is moved perpendicular to the rolling line or conveying line x-x via a travel drive 10 and a carriage 9 guided by rails. Said trolley frame 9 is connected to a movable part 2' of said roller table 2 and moves together with the shearer 3 in such a way that when the shearer 3 is as figure 1 When shown outside the roll line x-x, move into the roll line x-x, and vice versa, re-enter the roller table 2 when the shearer 3 moves out.

[0027] Such as figure 1 As shown, at least one clamping part 7 with actuating means 11 , 25 , 30 , 36 is arranged at the roller table-side end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com