Sensing head drive

A sensing head and drive technology, which is applied to the configuration/installation of instruments and heads, recording/reproduction by optical methods, etc., can solve the problems of increased manufacturing cost and complicated manufacturing process of optical sensing head devices, and achieve simplified manufacturing Process, the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

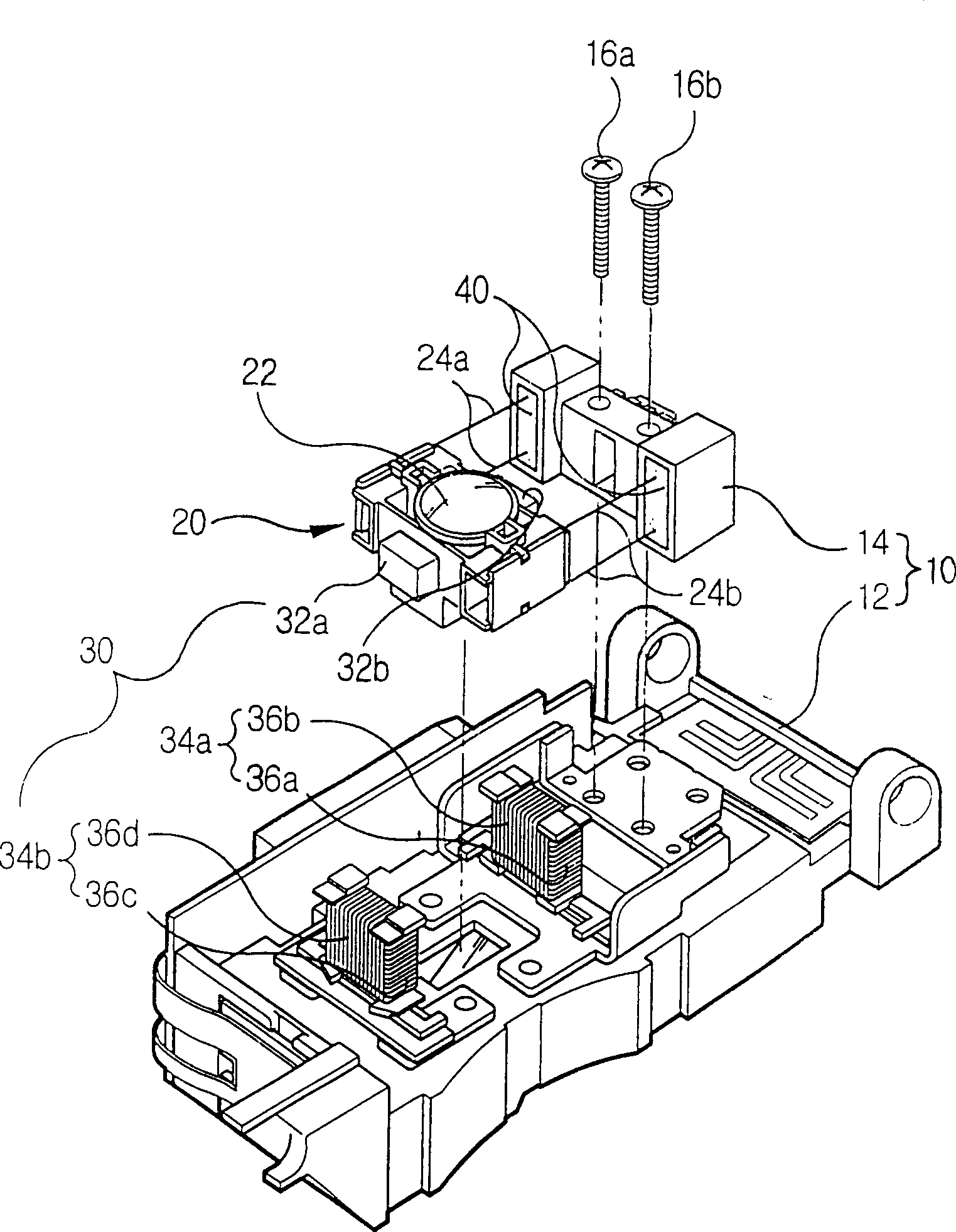

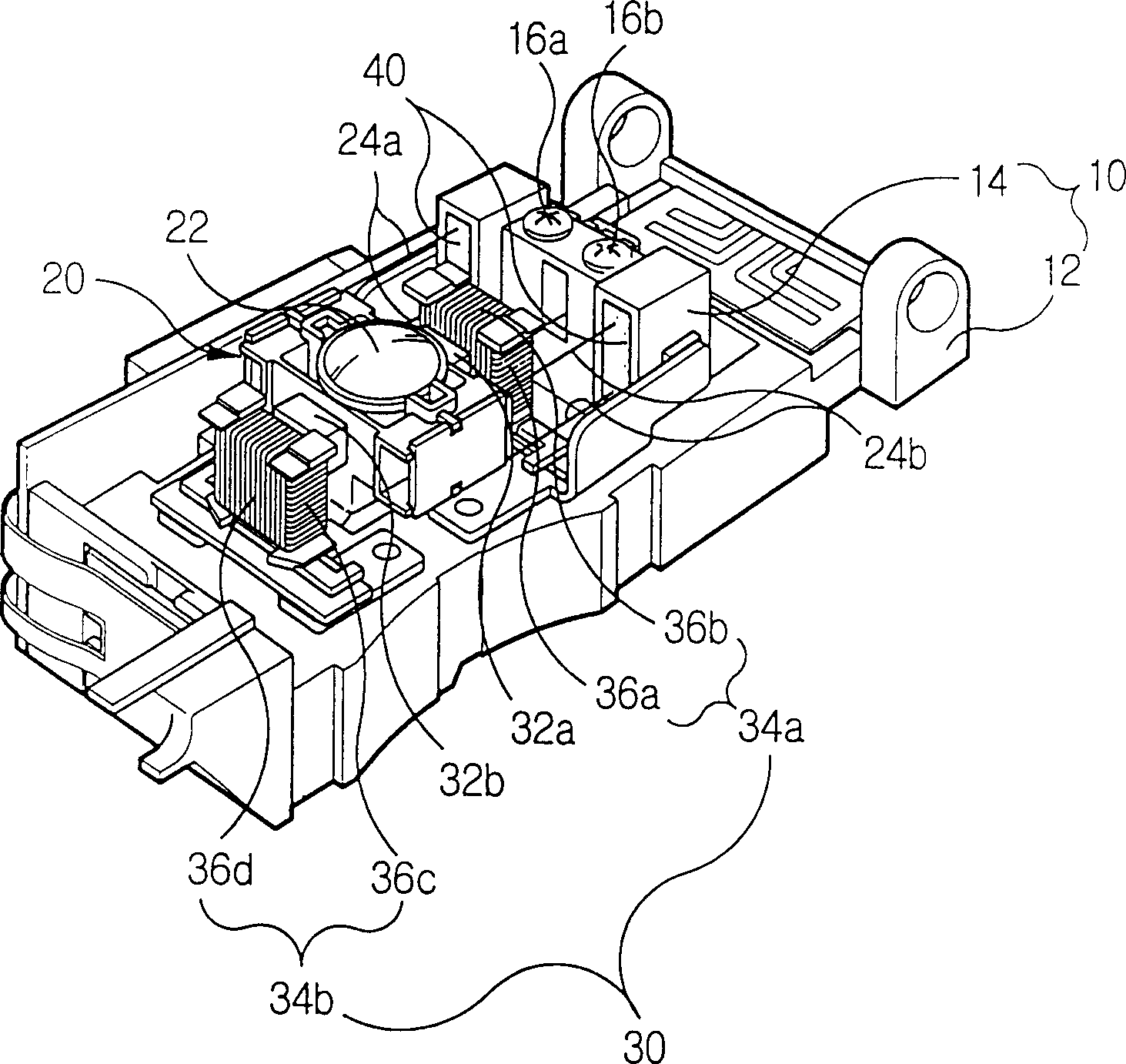

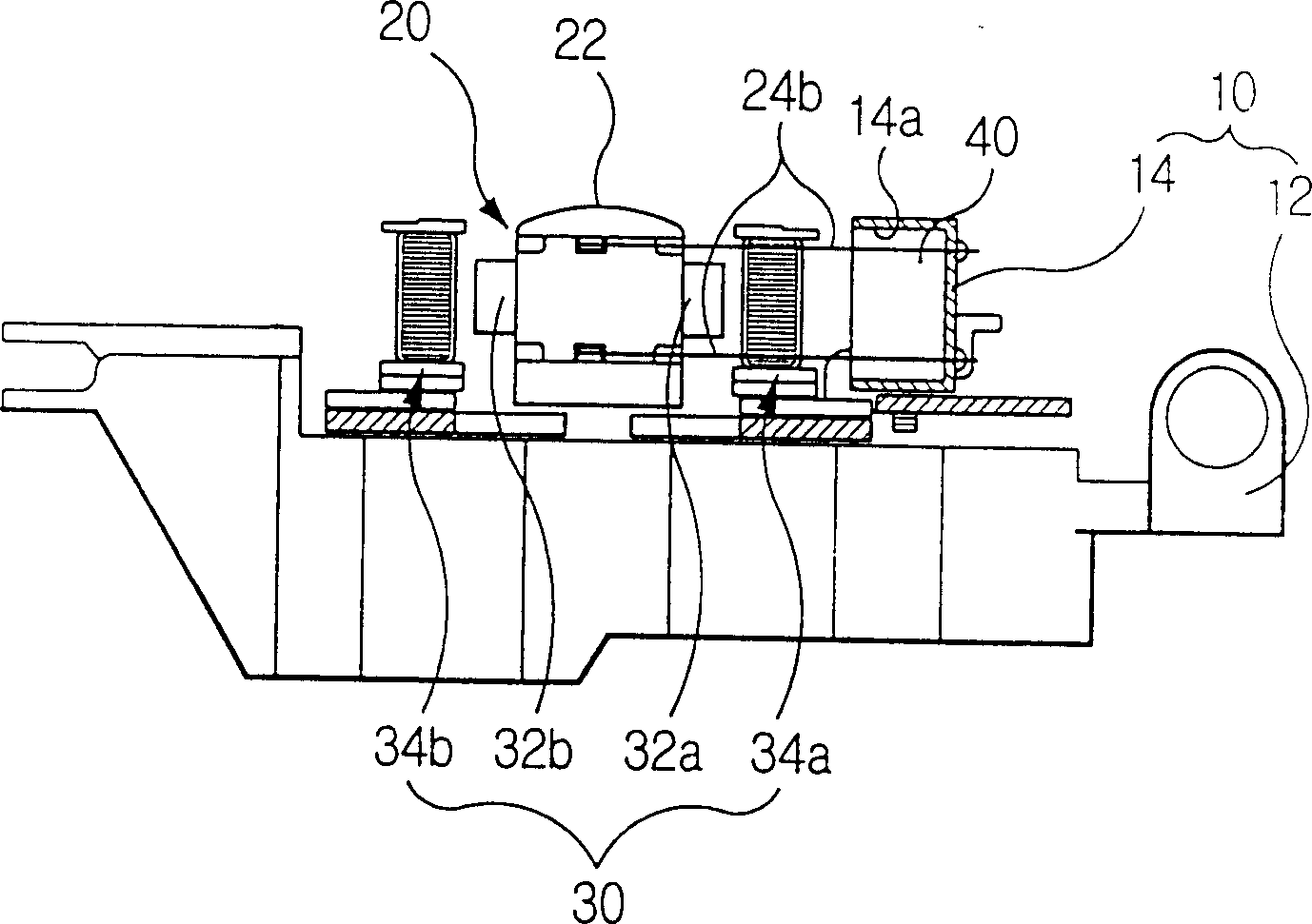

[0060] Figure 5A to Figure 6 Shows the sensor head driver according to the first preferred embodiment of the present invention. It will be found that the marking numbers on the same components are also the same. Correspondingly, the reference numeral 10 in these figures denotes a base member, 20 denotes a lens holder, 30 denotes a lens holder driving device, and 50 denotes a damping fluid.

[0061] Such as Figure 5A to Figure 6 As shown, the base member 10 includes a body portion 12 and a holder support portion 14. The holder supporting part 14 is fixed to the upper part of the body part 12 by a pair of screws 16a and 16b.

[0062] An objective lens 22 is mounted on the lens holder 20. The lens holder 20 is suspended on the holder supporting portion 14 of the base member 10 by two pairs of wire springs 24a and 24b, and can move in the focusing direction and the tracking direction at the same time.

[0063] The lens holder driving device 30 includes a pair of magnets 32a and 32b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com