Microwave oven

A microwave oven and microwave technology, applied in microwave heating, electric/magnetic/electromagnetic heating, electrical components, etc., can solve problems such as difficult heating methods, and achieve the effect of improved left-right symmetry and large degrees of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

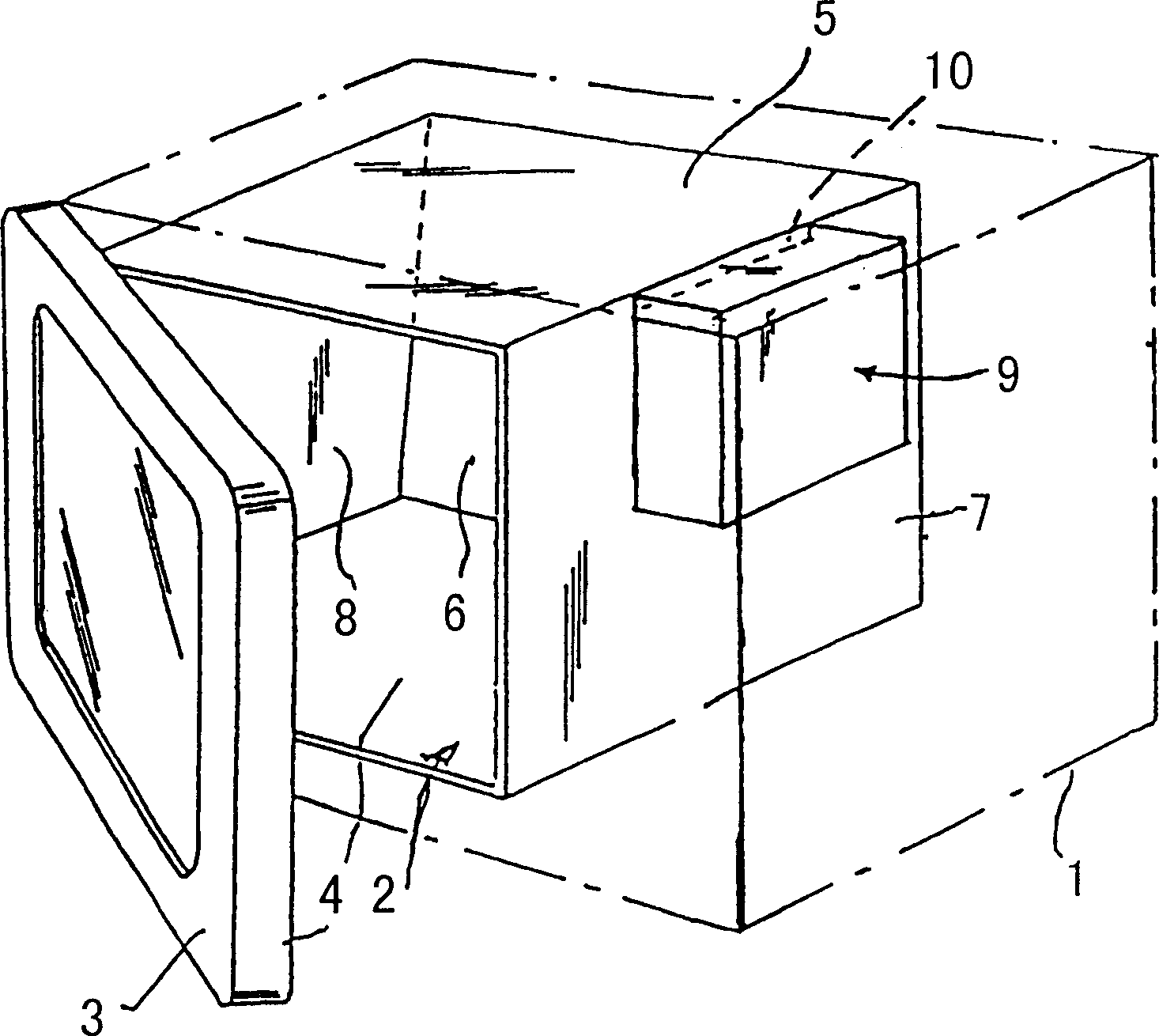

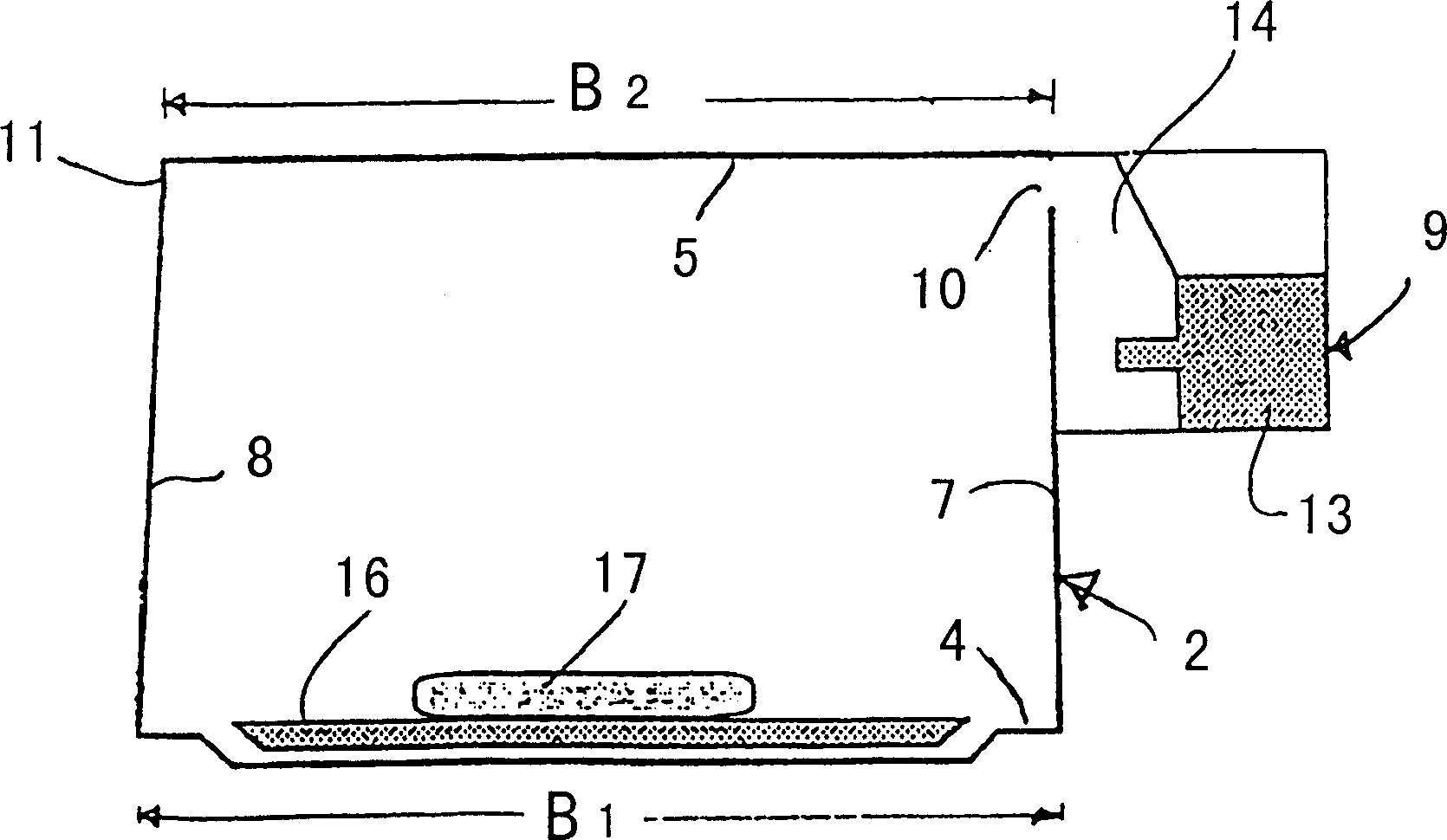

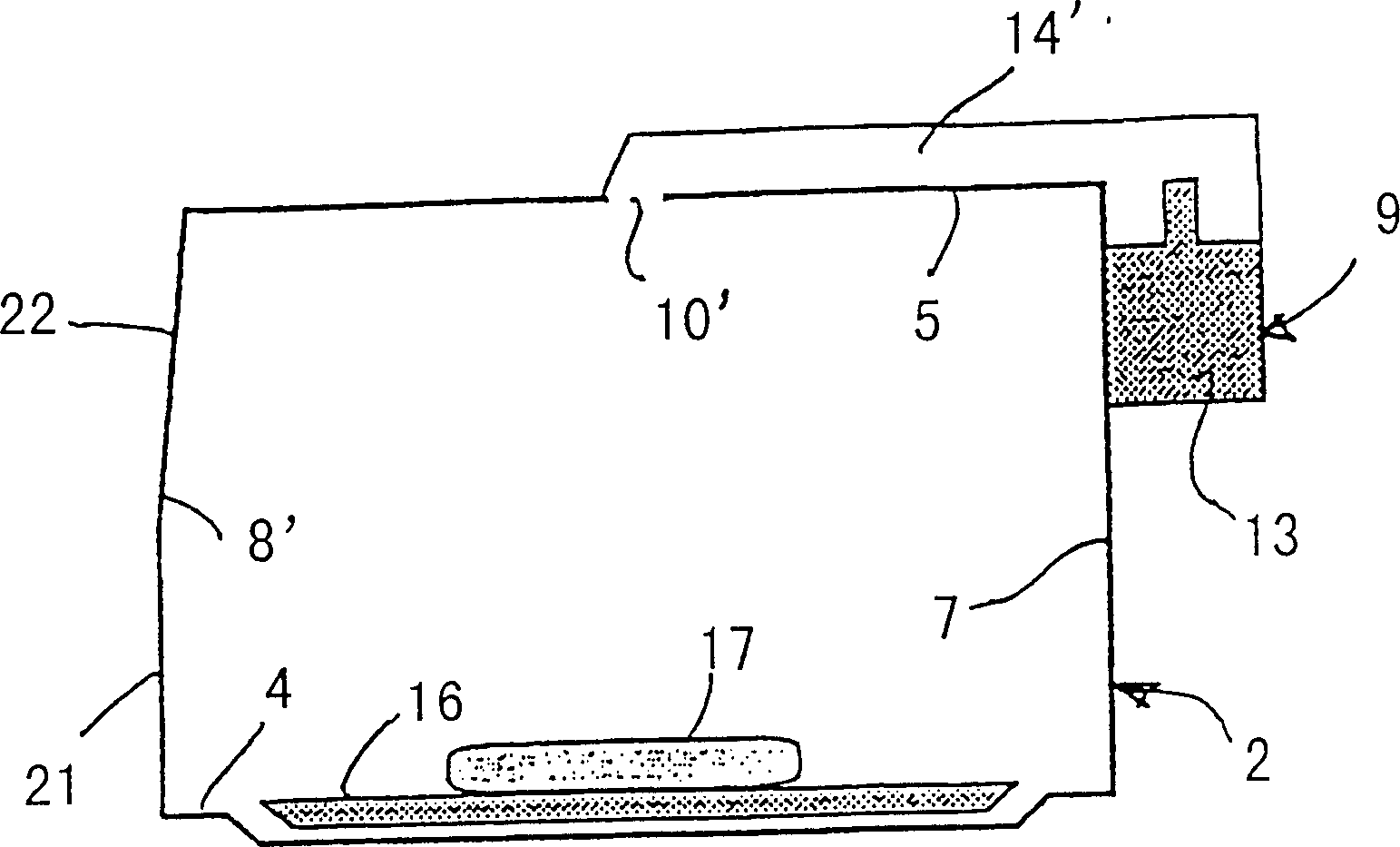

[0039] figure 1 and figure 2 The illustrated embodiment of the microwave oven according to the invention comprises an outer housing 1 , shown only roughly, and an oven cavity 2 , which is closed by means of a front door 3 . The cavity 2 consists of a horizontal cavity bottom 4 , a horizontal cavity top 5 , a vertical rear cavity wall 6 , a front vertical wall on the inside of the front door 3 and two cavity side walls 7 , 8 . exist figure 1 and figure 2 The right side wall 7 is vertical and equipped with a microwave device for feeding microwaves into the oven cavity through the slot-shaped rectangular side wall opening 10, for example as will be described in detail below. figure 1 and figure 2 The left side wall 8 is inclined somewhat inwardly and thus forms an angle of approximately 3° with respect to the vertical. Thus, apart from the inward slope of the side walls 8, the cavity is a cuboid. However, said inward slope is so small that no substantial difference from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com