Plastic box

A box and plastic technology, applied in the field of machinery, can solve the problems of being unable to be stacked together, occupying a large area, and high transportation costs, etc., to achieve the effects of saving transportation costs, easy breathing, and saving storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

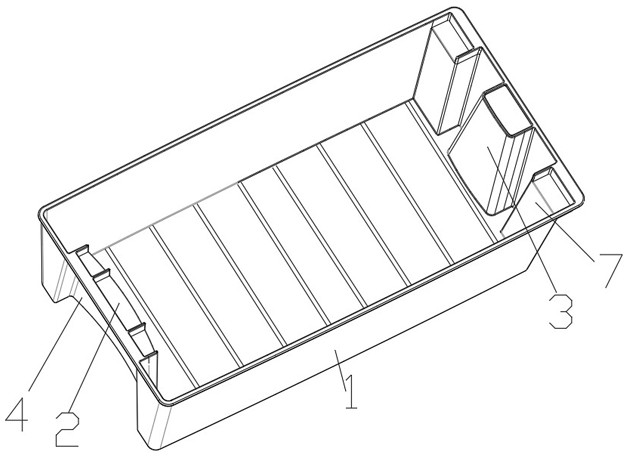

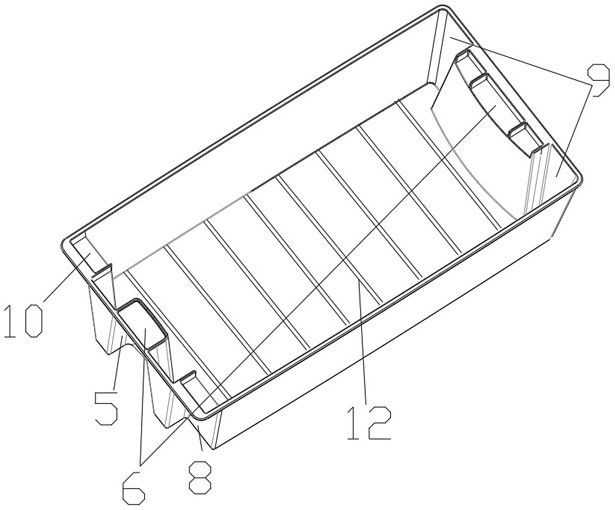

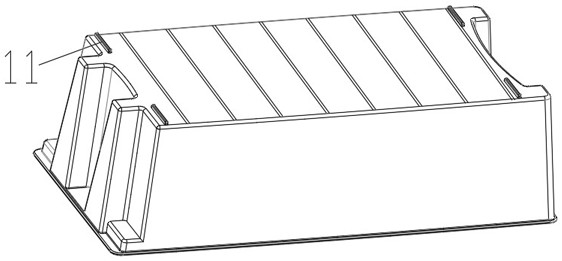

[0022] like figure 1 and figure 2 The shown plastic box includes a box body 1, a first raised portion 2, a second raised portion 3, a first guide groove 4, a second guide groove 5, a support plate 6, a support portion 7, and a guide groove 8 , the first avoidance groove 9 , the second avoidance groove 10 , the positioning protruding strips 11 and the decorative stripes 12 .

[0023] Wherein, the middle part of the left inner wall of the box body 1 is formed with a first raised part 2, and the middle part of the right inner wall is formed with a second raised part 3; the first raised part 2 and the second raised part 3 Both are gradually narrowed from the bottom to the top, and the second raised portion 3 is smaller than the first raised portion 2; The outer sides of the second raised portions 3 are the second guide grooves 5 that cooperate with the second raised portions 3 ; the tops of the first guide grooves 4 and the second guide grooves 5 are fixed with a support plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com