Automatic cotton bale packaging device and packaging production line

An automatic packaging and production line technology, applied in the direction of wrapping paper bending device, packaging material feeding device, packaging, etc., can solve the problems of consuming large manpower and material resources, increasing costs, and low production efficiency, so as to reduce labor intensity and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

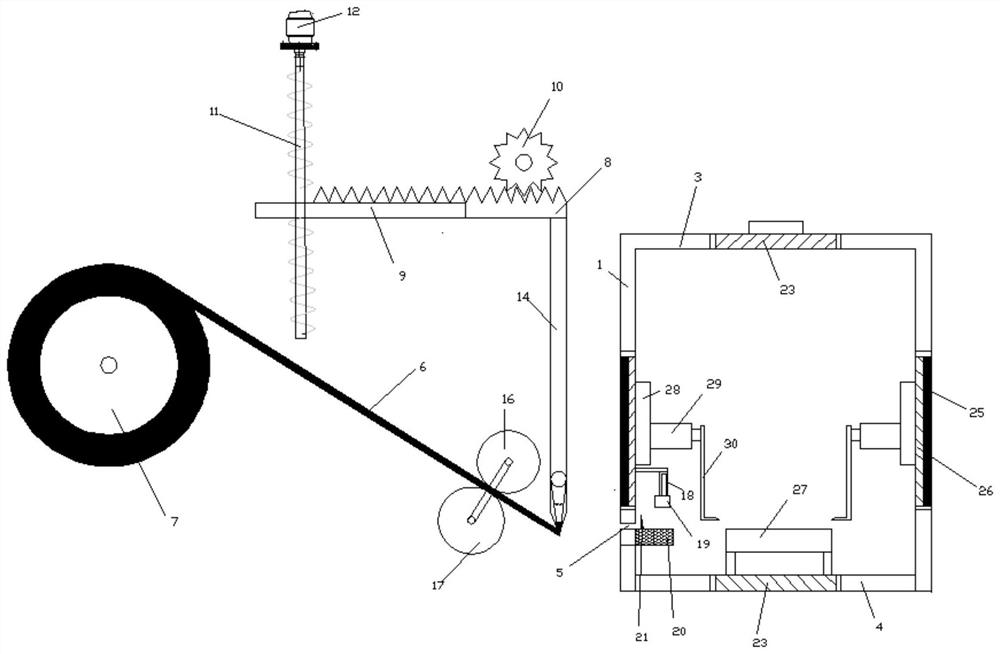

[0029] This embodiment provides an automatic packaging device for cotton bale, which is used for wrapping a packaging film on the outer surface of a cotton bale with a rectangular parallelepiped structure.

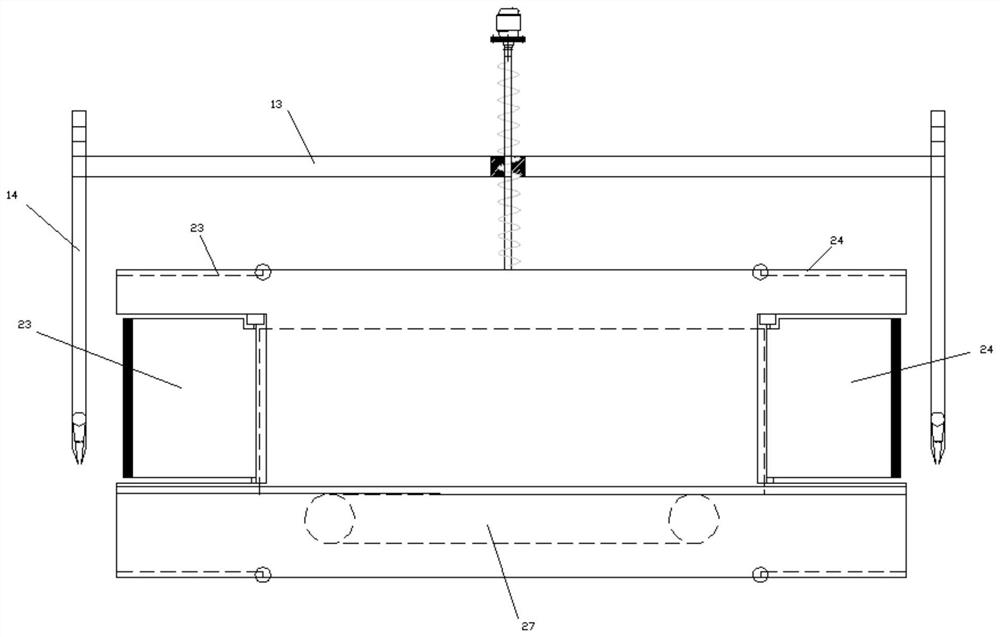

[0030] like Figure 1-Figure 5 As shown, the cotton bale automatic packaging device includes a box, which is fixed on the box bracket and has a set distance from the ground foundation. The box adopts a cuboid structure with open ends at both ends, including a front box wall 1, a rear box wall 2. Upper box wall 3 and lower box wall 4.

[0031] An opening 5 is provided at the bottom position of the front box wall of the box body. The opening 5 is arranged along the length direction of the box body. The opening 5 is used for the packaging film 6 to enter the inside of the box body.

[0032] A film roller 7 is provided on one side of the front box wall of the box body, the film roller 7 is rotatably connected with the film roller frame, and the film roller 7 is used for wrapp...

Embodiment 2

[0079] This embodiment provides an automatic cotton bale packaging production line, including the cotton bale automatic device described in Embodiment 1. One side of the open end of the box body is provided with a bale feeding transmission mechanism, which is used as the bale feeding end. One side of the open end of the other end is provided with a package delivery mechanism as the package delivery end.

[0080] Both the in-packet transmission mechanism and the out-pack transmission mechanism adopt the existing belt transmission mechanism, the top surface height of the in-packet transmission mechanism is slightly higher than the top surface height of the in-box transmission mechanism, and the top surface height of the in-box transmission mechanism is slightly higher at the height of the top surface of the out-pack conveyor.

[0081] The box is provided with an in-box conveying mechanism, and the inner sides of the front box wall and the rear box wall of the box are provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com