Bag cage for pleated filter bag and processing technology of bag cage

A processing technology and filter bag technology, applied in the field of bag cages for pleated filter bags and their processing technology, can solve the problems of reduced production efficiency of bag cages, difficult welding operations, and affecting structural strength, so as to improve adaptability and save Welding fixation, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

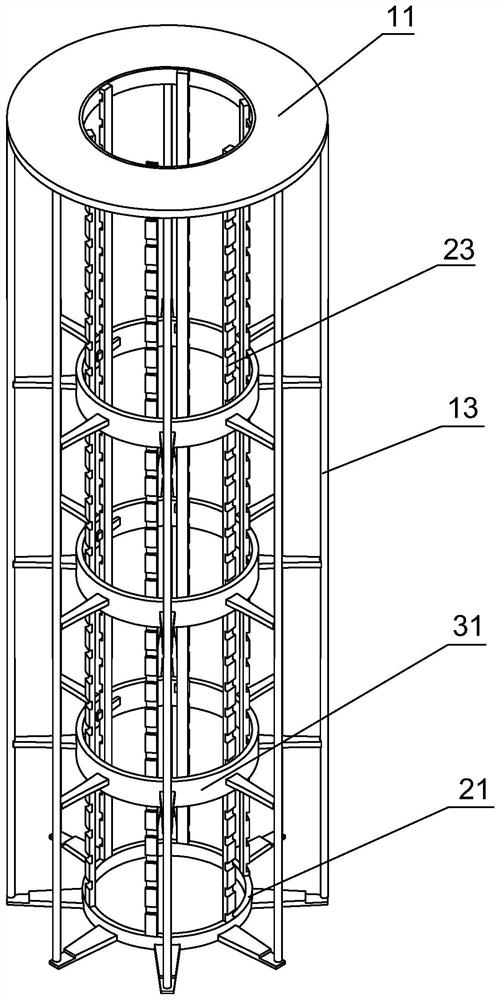

[0030] A bag cage for pleated filter bags includes an outer unit 100 , an inner unit 200 and an inner lining unit 300 .

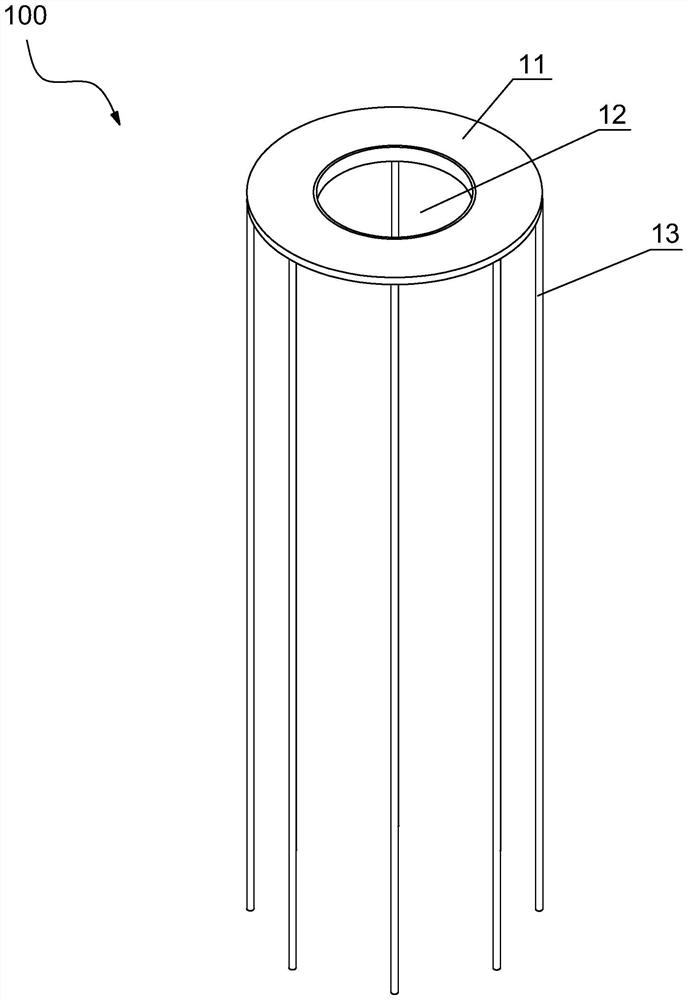

[0031] refer to figure 1 and figure 2 , the external unit 100 includes a top cover 11 with a ventilation channel 12 opened in its middle position, the top cover 11 is annular, and the outer edge of the top cover 11 is provided with a plurality of external ribs 13 extending in the same side direction, and the external ribs 13 Vertical to the surface of the top cover 11 , the plurality of outer ribs 13 are distributed in a ring-shaped array. In this embodiment, there are preferably eight outer ribs 13 .

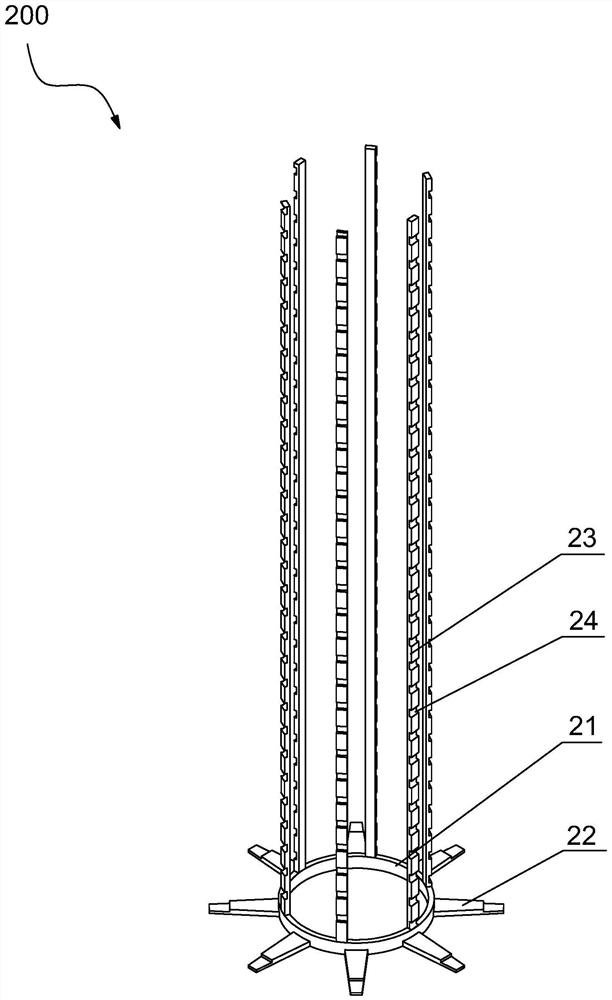

[0032] refer to figure 1 and image 3 , the internal unit 200 includes a bottom bracket 21, the bottom bracket 21 is annular, a plurality of support arms 22 are welded and fixed on the peripheral side of the bottom bracket 21, and the plurality of support arms 22 are distributed in an annular array and correspond to the outer ribs 13 one-to-one . The i...

Embodiment 2

[0036] A processing technology of a bag cage for pleated filter bags, refer to Figure 5 , including the following steps:

[0037] In step 1, the steel plate is segmented, cut and welded to manufacture the independent inner unit 200 , outer unit 100 and inner lining unit 300 .

[0038] The steel bars are cut in sections to produce a plurality of outer bars 13 of equal length. After laser cutting the flat steel plate, the top cover 11, the bottom bracket 21, the support arm 22 and the support rod 32 are produced and then refined again. After wire-cutting the cylindrical steel plate, the inner rib 23, the clamping block 33, and the support ring 31 are produced and refined again. A plurality of outer ribs 13 are welded on one side of the top cover 11 to make an independent external unit 100 , a plurality of support arms 22 are welded on the peripheral side of the bottom bracket 21 , and a plurality of inner ribs 23 are welded on one side to form an independent external unit 100 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com