Immersed tube joint floating condition calibration method

A calibration method and tube section technology, applied in complex mathematical operations, instruments, measuring devices, etc., can solve problems such as poor floating state calibration accuracy, reduce costs and difficulties, improve floating state calibration accuracy, and improve sinking installation accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

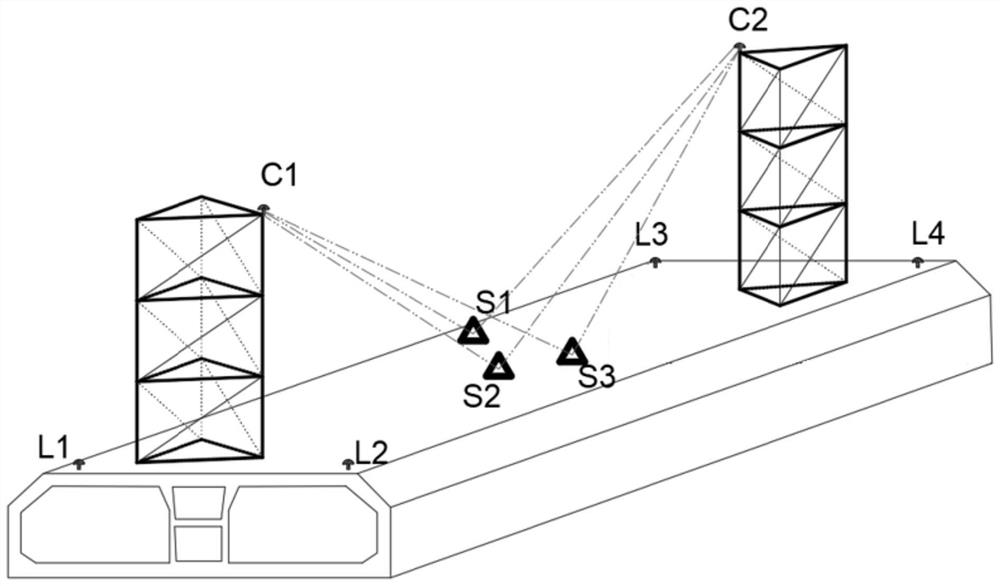

[0053] refer to figure 2 As shown, the present invention provides a method for calibrating a floating state of an immersed tube section, comprising the following steps:

[0054] 1) Prefabricate the pipe section in the dry dock area and establish the pipe joint coordinate system. At least three non-collinear characteristic points S1, S2 and S3 of the middle section of the pipe top are arranged in the middle section of the top surface of the pipe section, and the three pipe tops are calibrated respectively. The three-dimensional coordinates of the mid-section feature points S1, S2, and S3 in the pipe joint coordinate system; further, the three pipe top mid-section characteristic points S1, S2, and S3 can be dispersed to correspond to different positions in the pipe section width direction, and the distance from each other should be as large as possible Preferably, two feature points can be arranged at both ends of the pipe section in the width direction, three feature points in...

Embodiment 2

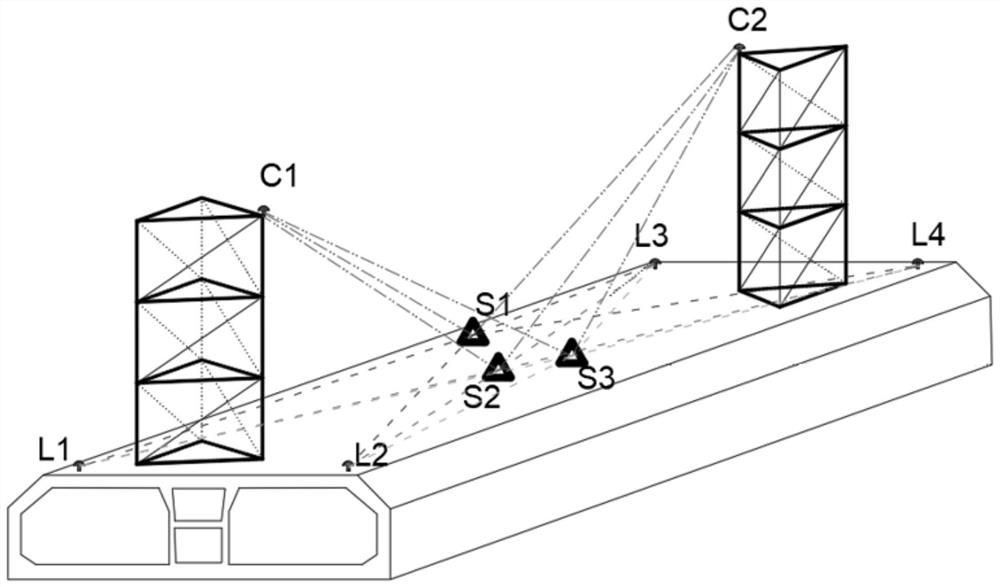

[0069] refer to image 3 As shown in the figure, the present invention also provides a method for calibrating the floating state of the immersed tube section. On the basis of the first embodiment, in order to ensure the robustness and reliability of the solution results, a spatial network is established to measure the characteristic points of the tower top. Calibration includes the following steps:

[0070] 1) Prefabricate the pipe section in the dry dock area and establish the pipe joint coordinate system, and arrange a pipe top feature point at each of the four corners of the top surface of the pipe section, denoted as L1, L2, L3, and L4, respectively. The three-dimensional coordinates of the feature points L1, L2, L3, and L4 at the top of each pipe in the pipe joint coordinate system; at least three non-collinear feature points S1, S2, S3 in the middle section of the pipe top are arranged in the middle section of the top surface of the pipe section. It should be noted that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com