Tandem heat exchanger thermal load distribution method for aero-engine fulcrum sealing

A technology of aero-engine and distribution method, applied in the direction of indirect heat exchanger, heat exchange equipment, lighting and heating equipment, etc., to achieve the effect of avoiding over-design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the implementation purpose, technical solutions and advantages of the present application clearer, the technical solutions in the embodiments of the present application will be described in more detail below with reference to the accompanying drawings in the embodiments of the present application.

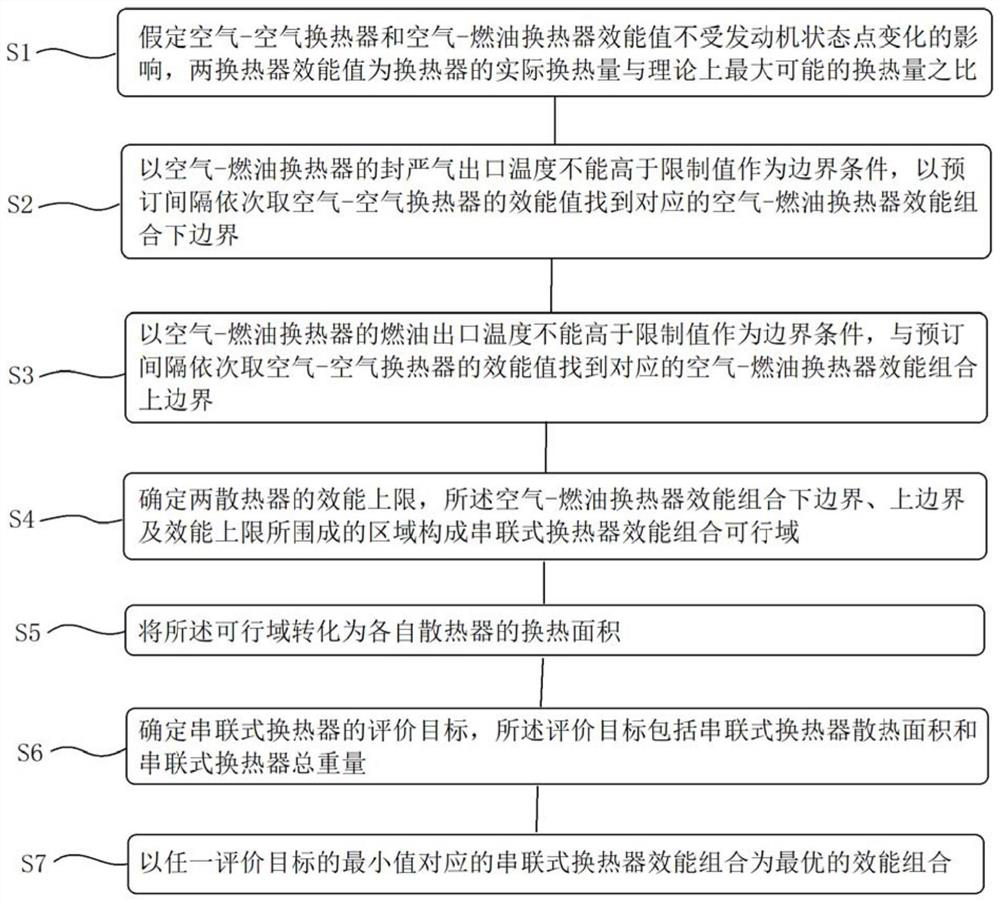

[0031] In order to find the performance combination of the series heat exchangers that meet the design requirements, and at the same time evaluate the performance combinations of the series heat exchangers that meet the design requirements, find the optimal combination of the series heat exchangers, and complete the heat load distribution, the application provides A method of heat load distribution for heat exchangers in series.

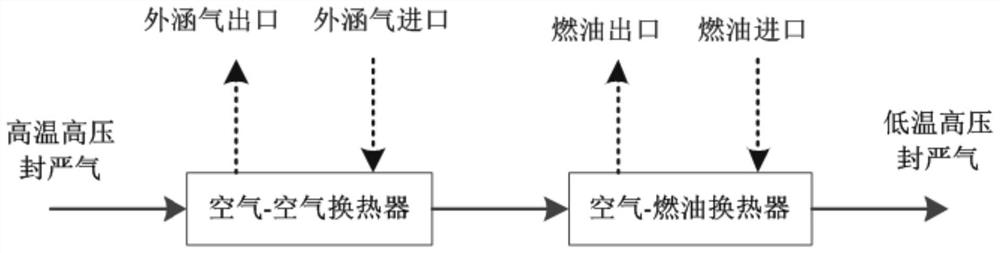

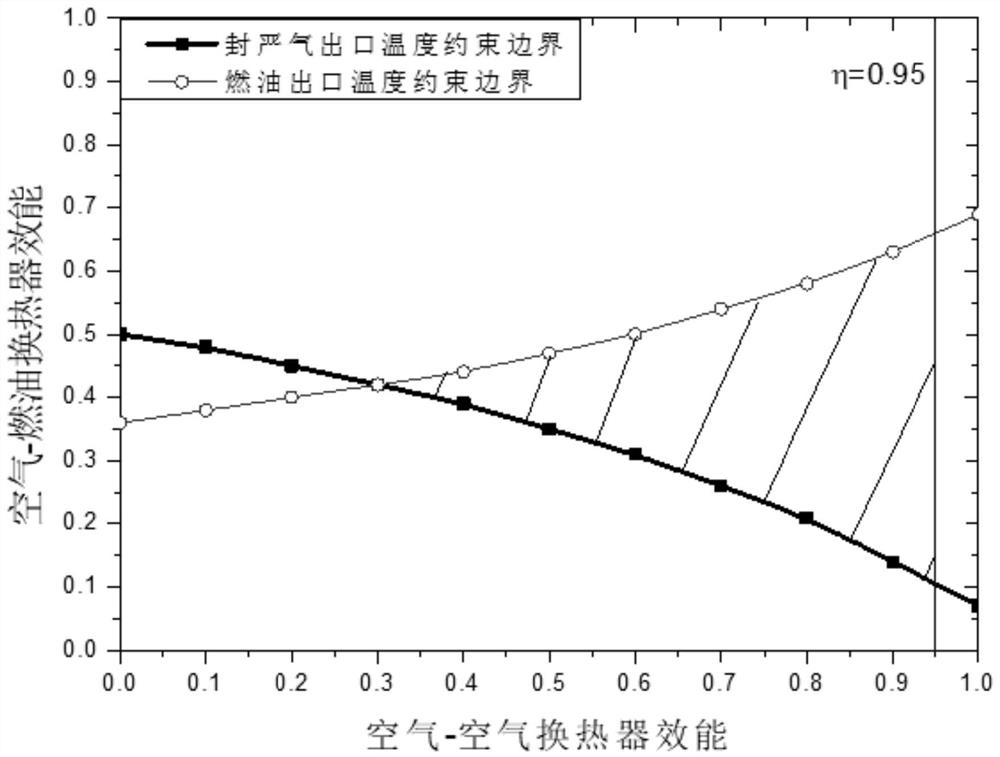

[0032] The method for distributing heat load to series-connected heat exchangers of the present application takes the condition that the outlet temperature of the hot side of the air-fuel heat exchanger does not exceed a certain lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com