Automatic sorting device for articles in logistics supply chain

A logistics supply chain, automatic sorting technology, applied in sorting and other directions, can solve problems such as affecting human health, manual sorting, unable to concentrate for a long time, unable to work for a long time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

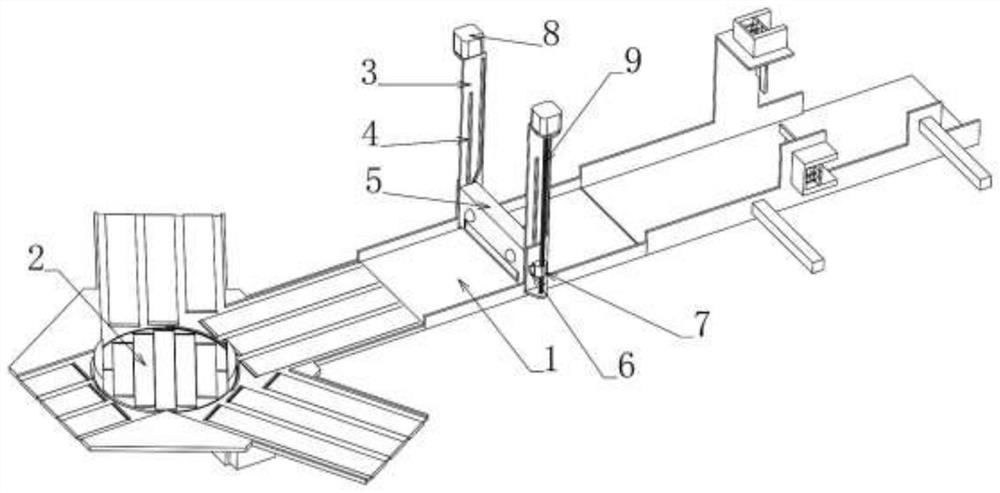

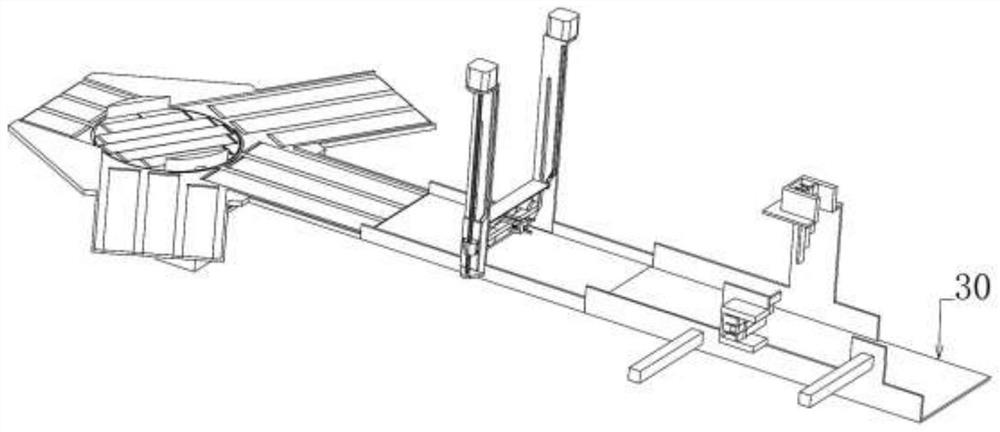

[0031] Attached to the following Figure 1-11 The specific embodiments of the present invention will be further described in detail.

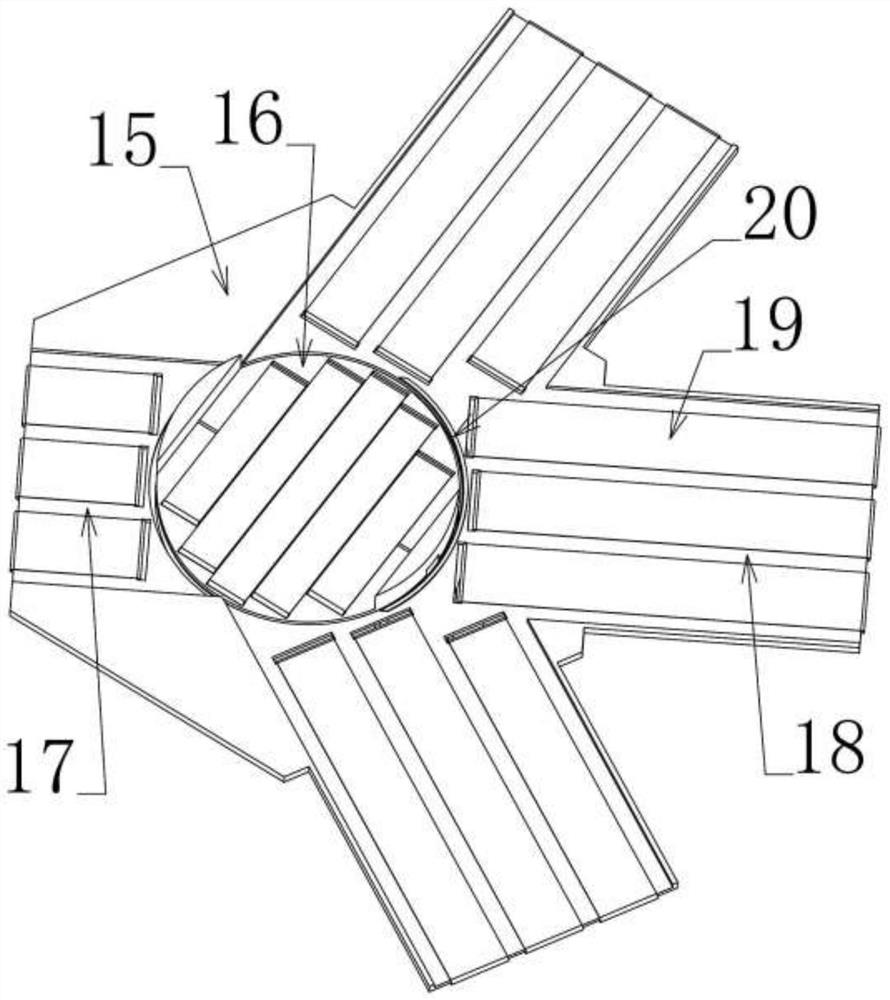

[0032] When this embodiment is used, the items that need to be classified are first packed into boxes, which are generally placed in a square box, and then an information label is affixed to the upper end of the box, which includes regional information, and then the items that need to be classified are They are placed on the conveyor belt 1 in turn, and then the items are sorted, detected and classified while being transported through the conveyor belt 1. First, the items are placed on the left end of the conveyor belt 1 when they are placed, and the conveyor belt 1 gradually removes the items during the conveying process. During the conveying process, the items will first pass through the sorting turntable 2, and then stay in the area of the sorting turntable 2 after touching the arc lift plate 20, and then pass the scanner located above the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com